NUP New Elastic Sleeve Pin Coupling

Category

Contact Information

Detailed introduction

Product Features

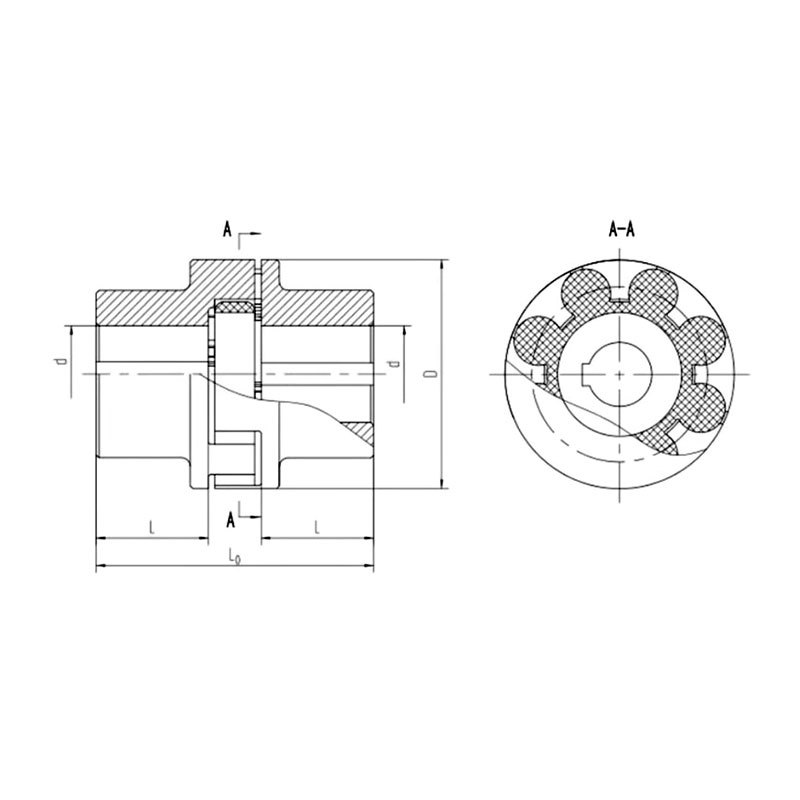

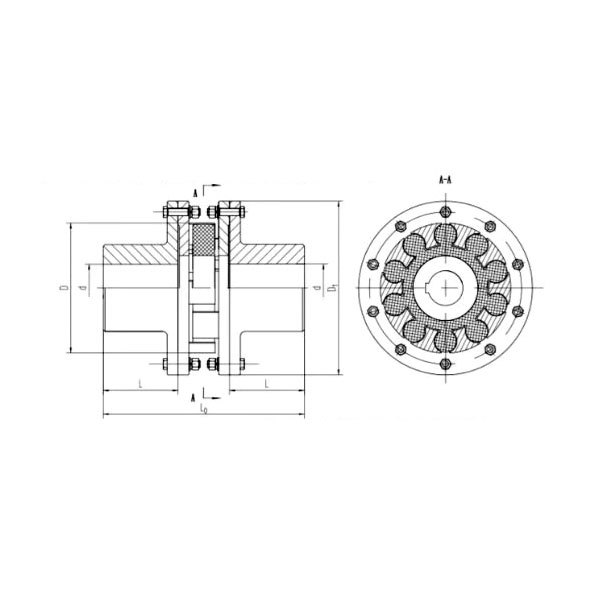

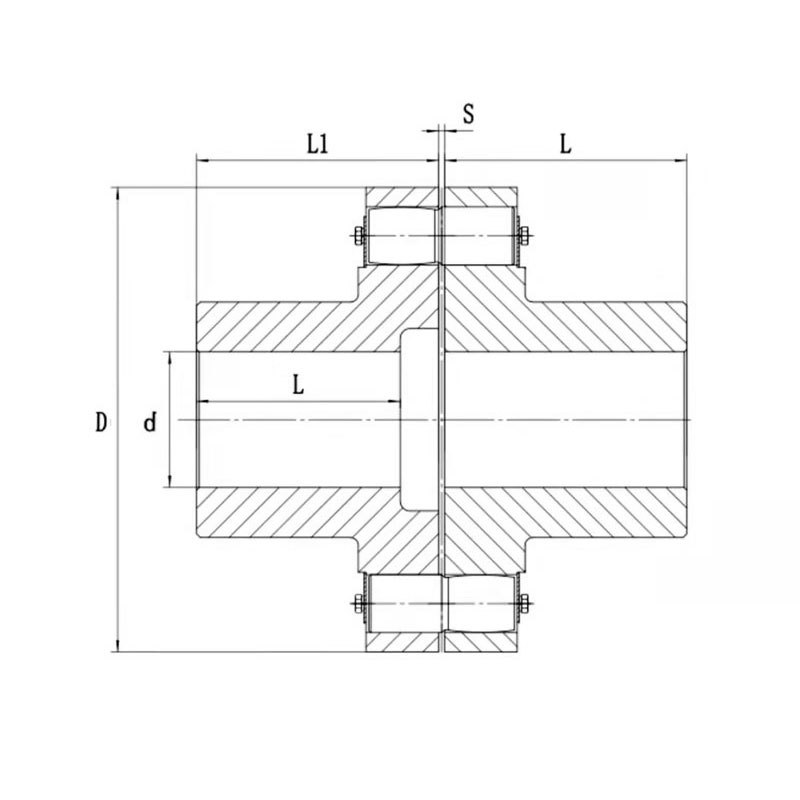

The NUP elastic sleeve material is made of polyurethane reinforced with graphite, offering excellent toughness, self-lubrication, and wear resistance. It features a hollow grid design and comes in three different elasticity options, providing vibration absorption and impact resistance. The tapered-hole bolts ensure a tight fit that prevents loosening.

Thanks to its high safety and reliability, as well as its outstanding vibration absorption and shock resistance capabilities, this coupling has received unanimous praise from over 100 users and has been awarded innovation funds by the Ministry of Science and Technology, the Provincial Department of Science and Technology, and the Municipal Science and Technology Commission.

Application scenarios

Torque is transmitted through elastic buffering, so the coupling typically exhibits flexible rubber-like properties. It is suitable for pumps, blower units, variable-frequency drive units, diesel engine sets, piston compressor units, and any rotating machinery subjected to impact loads, effectively addressing the challenge of high-frequency torsional oscillations in their transmission systems.

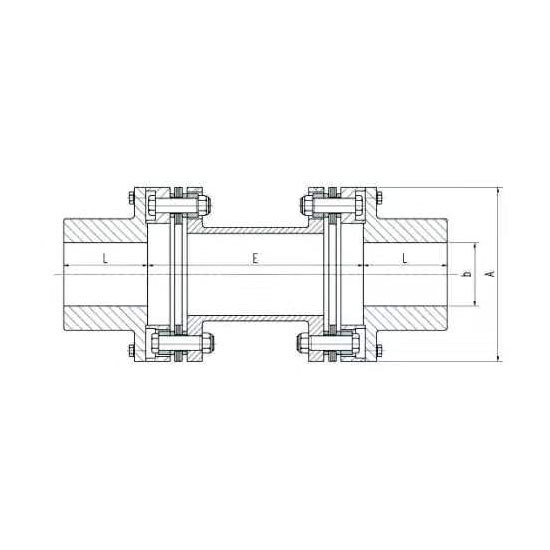

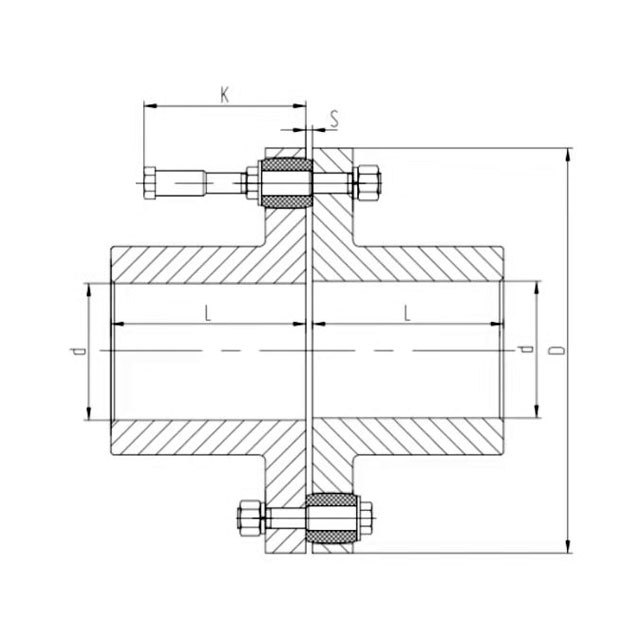

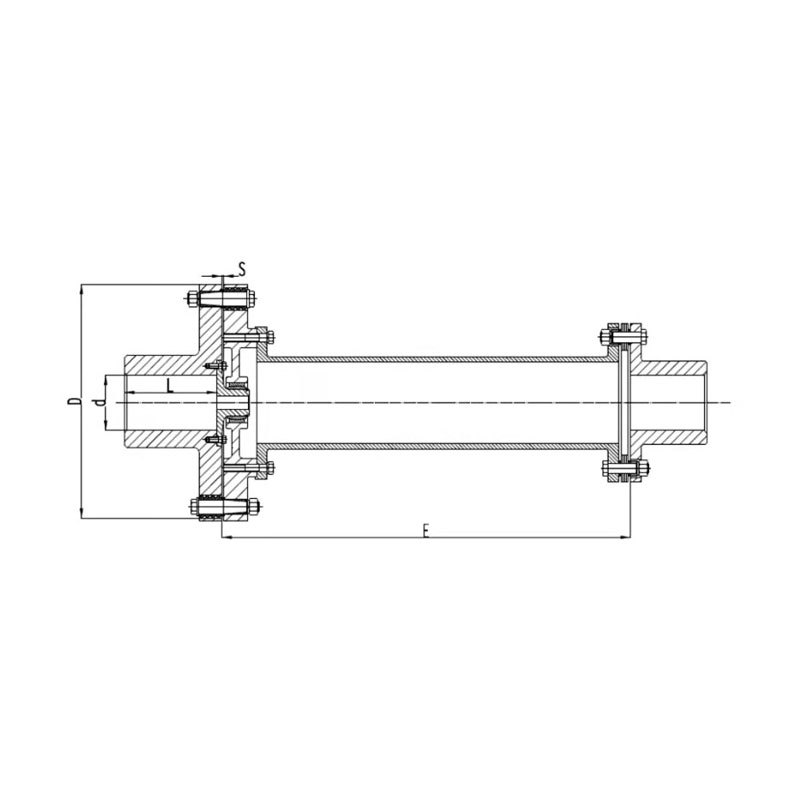

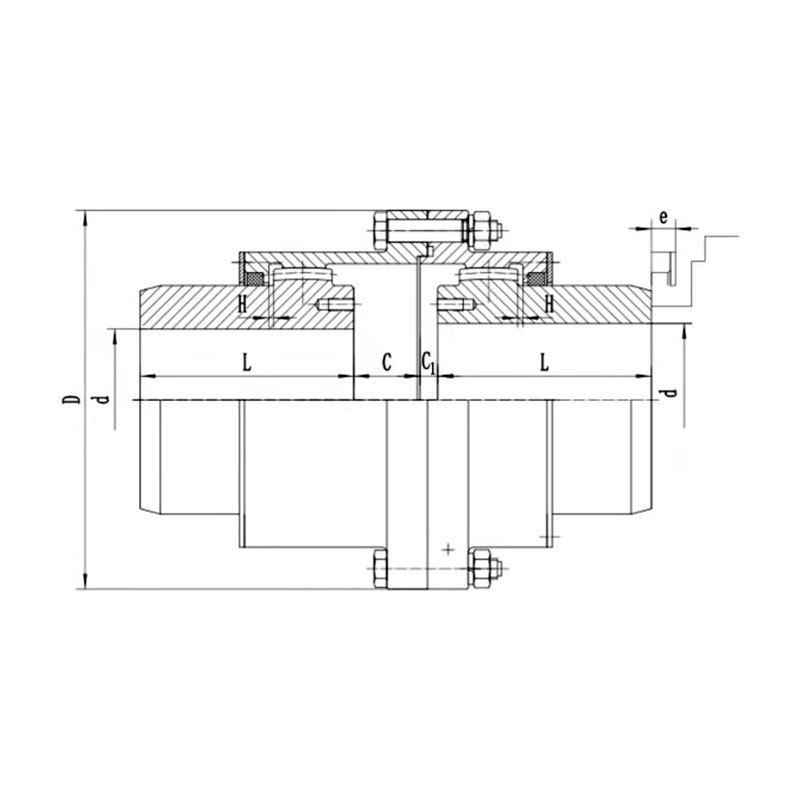

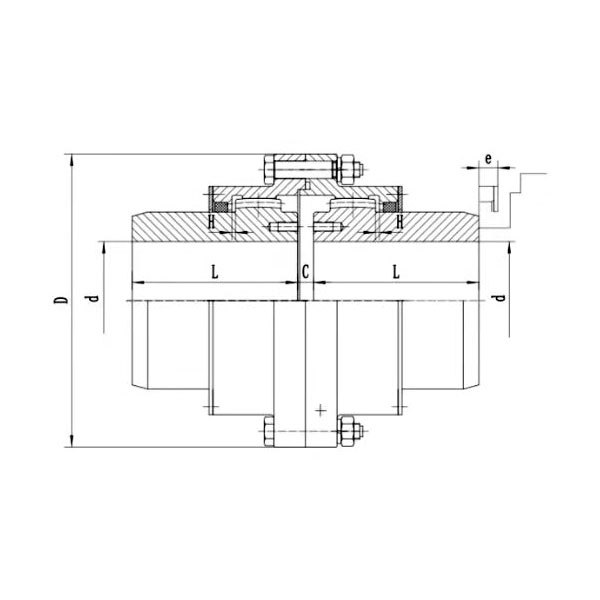

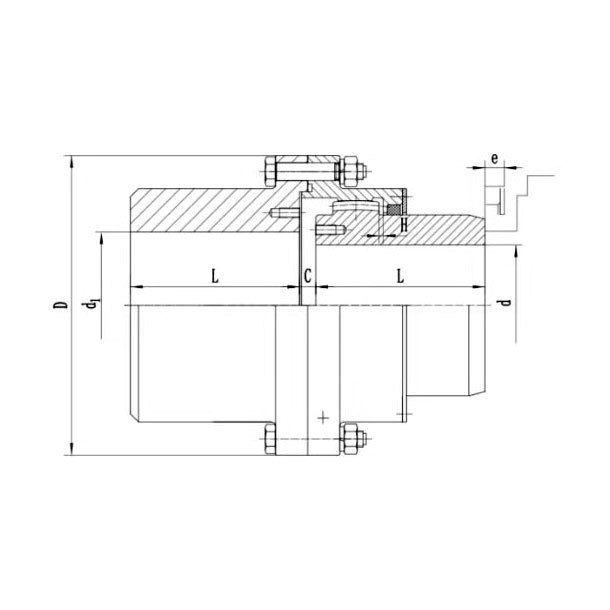

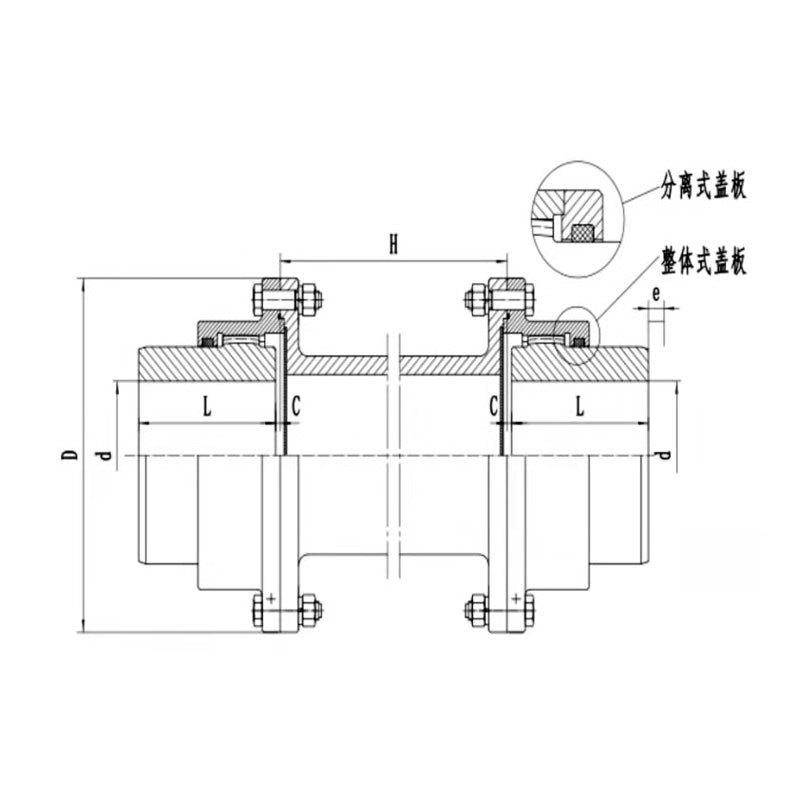

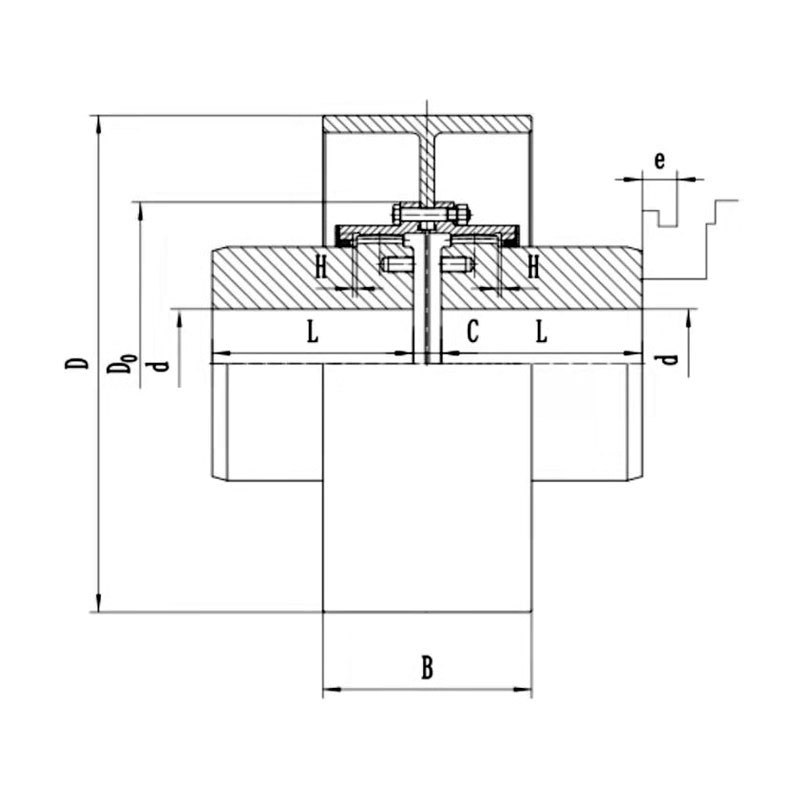

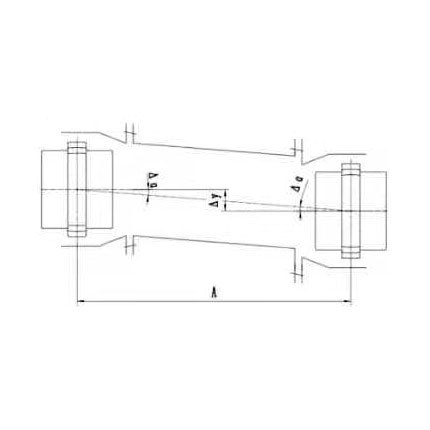

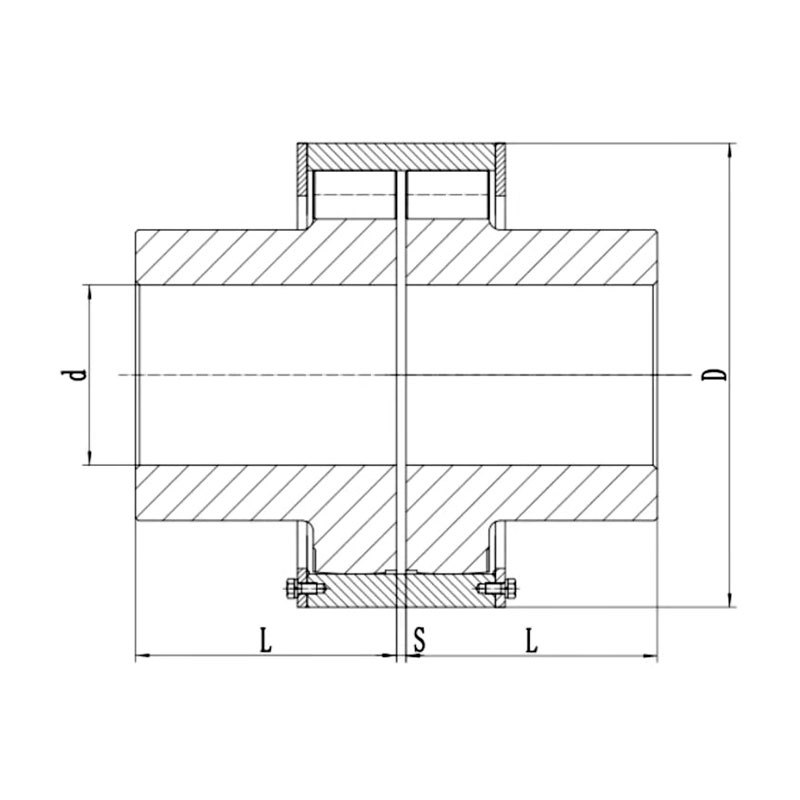

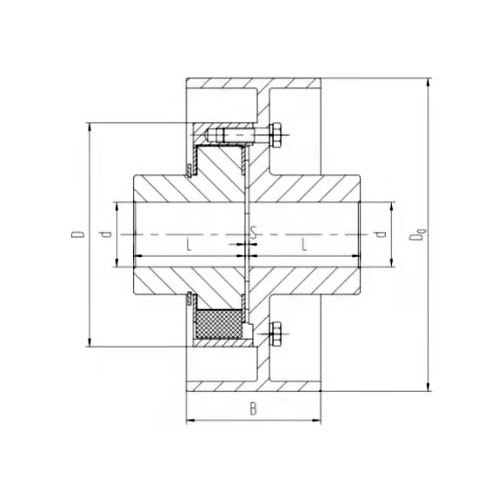

Its structural configuration is shown in Figure 3.1, and the technical parameters and main dimensions are listed in Table 3-1.

Figure 3.1 NUP Elastic Sleeve Pin Coupling

Table 3-1: Technical Parameters and Main Dimensions of the NUP Elastic Sleeve Pin Coupling

| Model | Rated torque Mr. N.m |

Peak torque City of Tp N.m |

Permissible Rotational Speed revolutions per minute |

D mm |

d Max mm |

S mm |

K mm |

Weight Kilogram |

Moment of inertia Kg·m² |

Torsional stiffness MNm/rad |

Misalignment absorption capability | ||

| Axial mm |

Angular direction · |

Radial mm |

|||||||||||

| NUP105 | 530 | 1060 | 5000 | 105 | 40 | 4 | 66 | 2.2 | 0.11 | 0.002 | 3 | 2 | 1 |

| NUP125 | 700 | 1400 | 5000 | 125 | 55 | 4 | 72 | 3.6 | 0.118 | 0.006 | 3 | 2 | 1 |

| NUP144 | 1100 | 2200 | 4900 | 144 | 60 | 4 | 99 | 5.5 | 0.126 | 0.01 | 3 | 2 | 1 |

| NUP162 | 1800 | 3600 | 4300 | 162 | 75 | 4 | 99 | 9.6 | 0.132 | 0.02 | 3 | 2 | 1 |

| NUP178 | 2100 | 4200 | 3800 | 178 | 80 | 4 | 99 | 12 | 0.14 | 0.036 | 3 | 2 | 1 |

| NUP198 | 2300 | 4600 | 3400 | 198 | 90 | 4 | 99 | 16.9 | 0.148 | 0.054 | 3 | 2 | 1 |

| NUP228 | 3600 | 7200 | 3000 | 228 | 100 | 5 | 106 | 24 | 0.159 | 0.114 | 3 | 2 | 1 |

| NUP252 | 5200 | 10400 | 2700 | 252 | 120 | 5 | 106 | 33 | 0.17 | 0.19 | 3 | 1.5 | 1 |

| NUP285 | 9000 | 18000 | 2400 | 285 | 130 | 5 | 133 | 47 | 0.179 | 0.35 | 4 | 1.5 | 1.2 |

| NUP320 | 11000 | 22000 | 2100 | 320 | 140 | 5 | 133 | 65 | 0.19 | 0.46 | 4 | 1.5 | 1.2 |

| NUP360 | 22000 | 44000 | 1900 | 360 | 160 | 5 | 138 | 92 | 0.2 | 0.13 | 4 | 1.5 | 1.2 |

| NUP400 | 27000 | 54000 | 1700 | 400 | 170 | 6 | 168 | 130 | 0.212 | 1.9 | 4 | 1.2 | 1.5 |

| NUP450 | 44000 | 88000 | 1500 | 450 | 195 | 6 | 196 | 200 | 0.22 | 3.6 | 4 | 1.2 | 1.5 |

| NUP500 | 54000 | 108000 | 1350 | 500 | 220 | 6 | 196 | 250 | 0.23 | 5.8 | 4 | 1.2 | 1.5 |

| NUP560 | 84000 | 168000 | 1200 | 560 | 235 | 6 | 241 | 320 | 0.24 | 10.4 | 4 | 1 | 1.5 |

| NUP630 | 95000 | 190000 | 1050 | 630 | 250 | 6 | 241 | 340 | 0.25 | 16 | 5 | 1 | 1.5 |

| NUP710 | 142000 | 284000 | 950 | 710 | 270 | 6 | 279 | 360 | 0.26 | 30 | 5 | 1 | 1.5 |

| NUP800 | 162000 | 324000 | 850 | 800 | 295 | 6 | 279 | 400 | 0.27 | 47 | 5 | 1 | 1.5 |

| NUP900 | 245000 | 490000 | 750 | 900 | 320 | 8 | 313 | 420 | 0.28 | 85 | 6 | 0.75 | 1.8 |

| NUP1000 | 280000 | 560000 | 680 | 1000 | 350 | 8 | 313 | 450 | 0.29 | 125 | 6 | 0.75 | 1.8 |

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products