G-type diaphragm coupling

Category

Contact Information

Detailed introduction

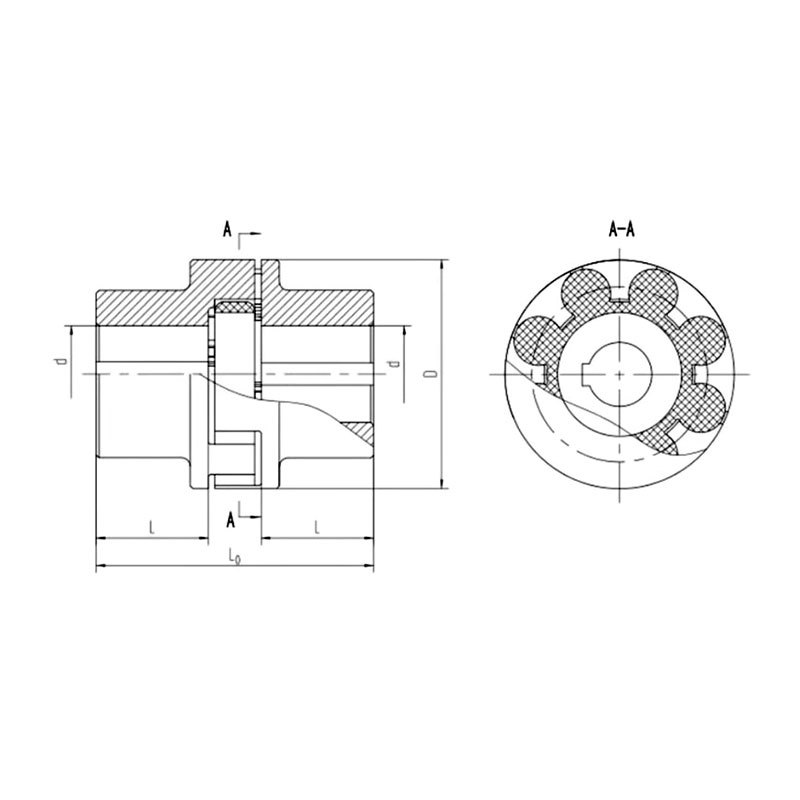

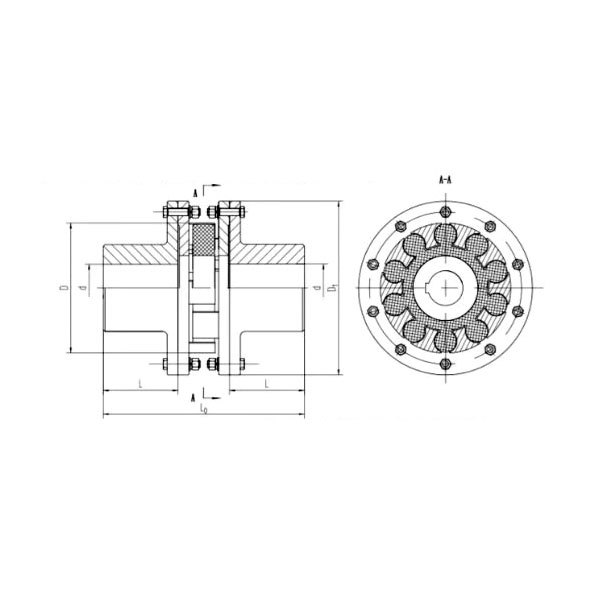

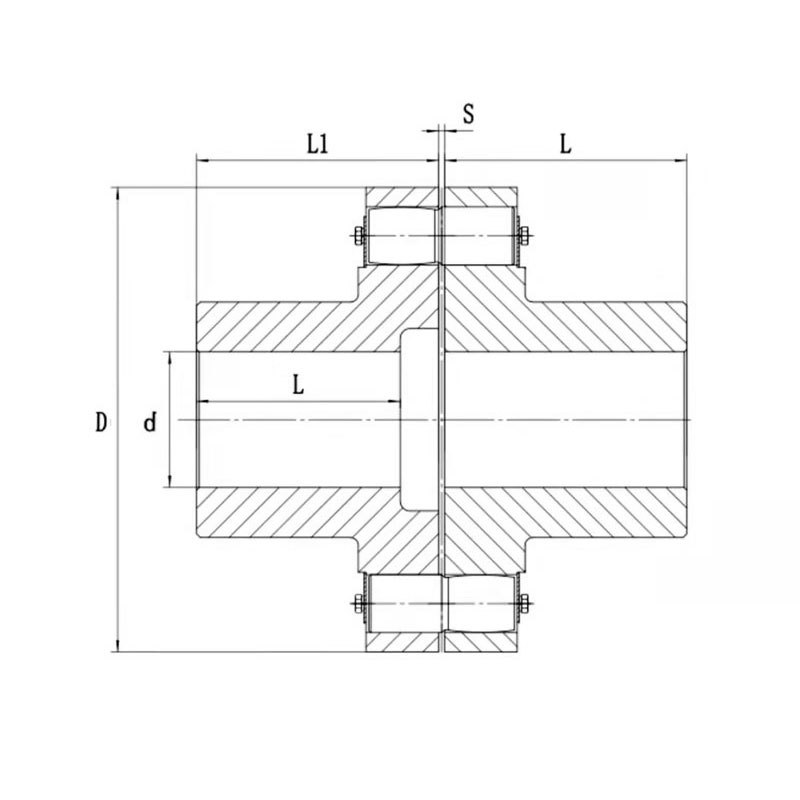

In addition to the key advantages of R-type couplings, the G-type coupling’s half-coupling features a larger shaft-diameter capacity and can be manufactured with either straight bores or tapered bores (for hydraulic assembly and disassembly), or it can be conveniently connected to flanged shaft hubs. The G-type is particularly well-suited for large electric motors, generators, or steam turbine units. Among all types of couplings, the G-type coupling is the easiest to assemble and disassemble.

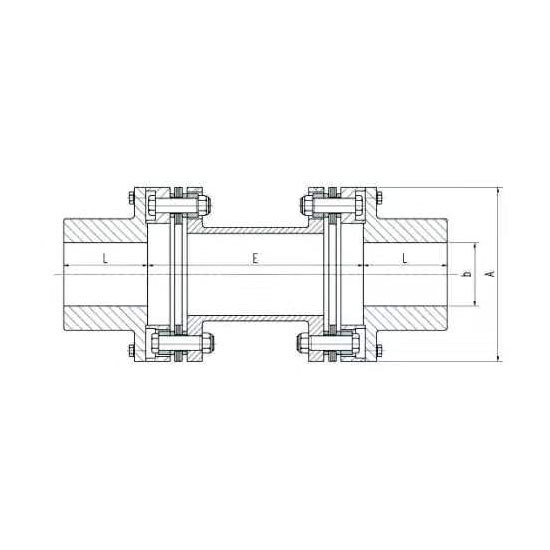

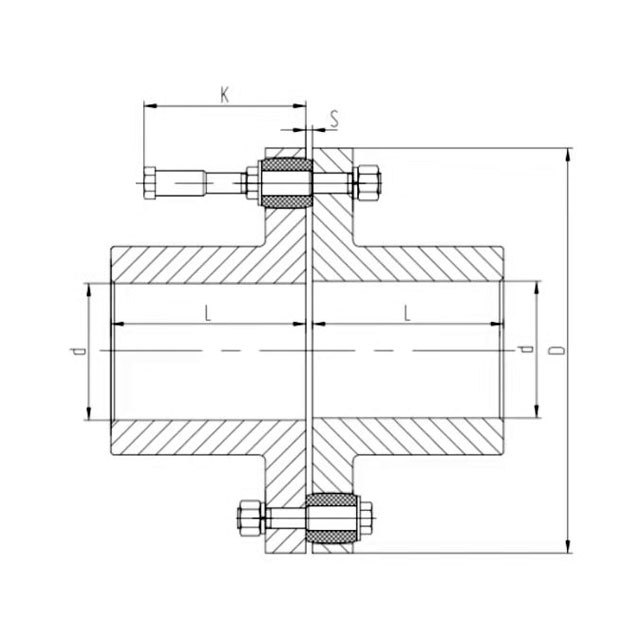

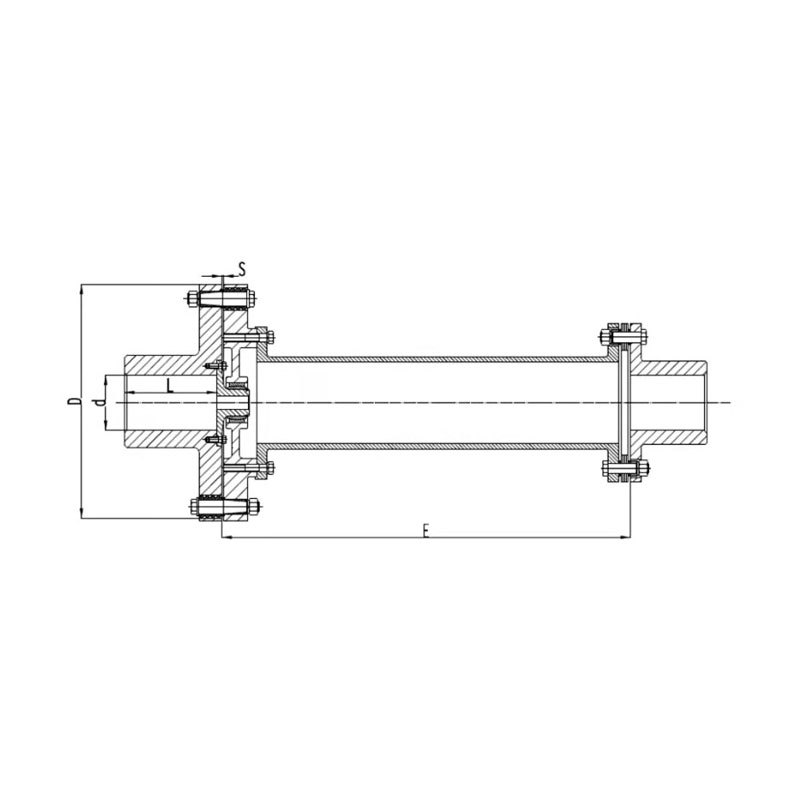

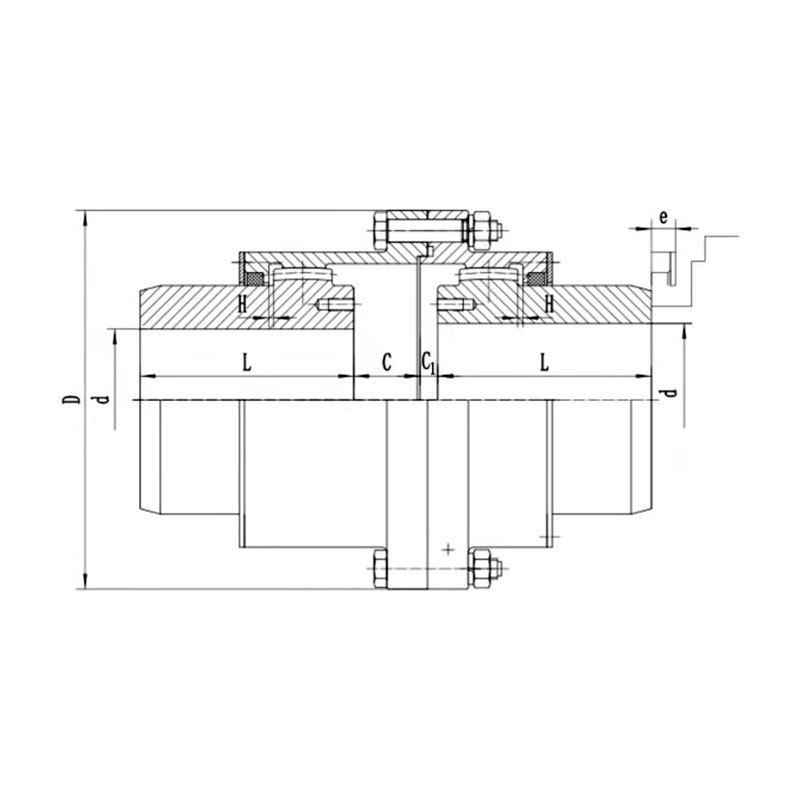

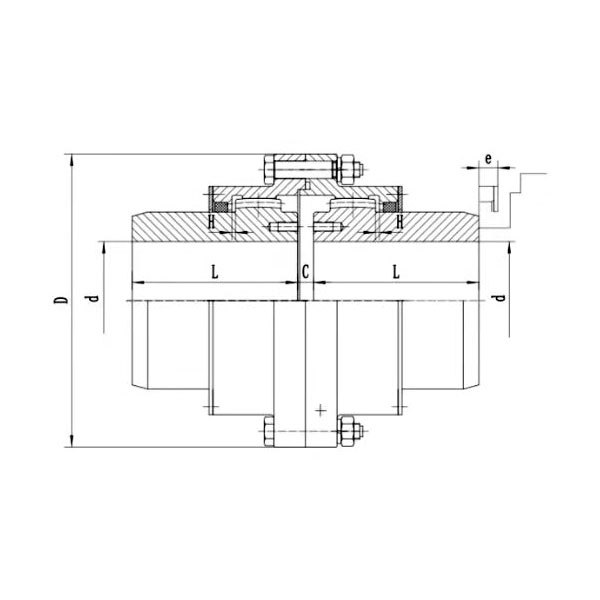

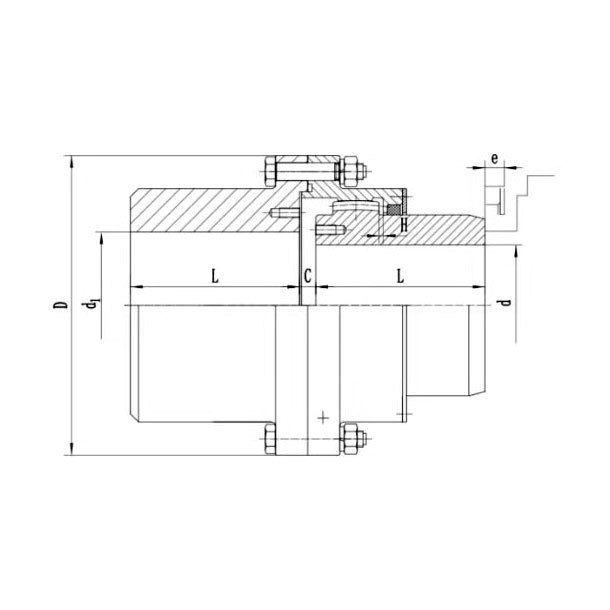

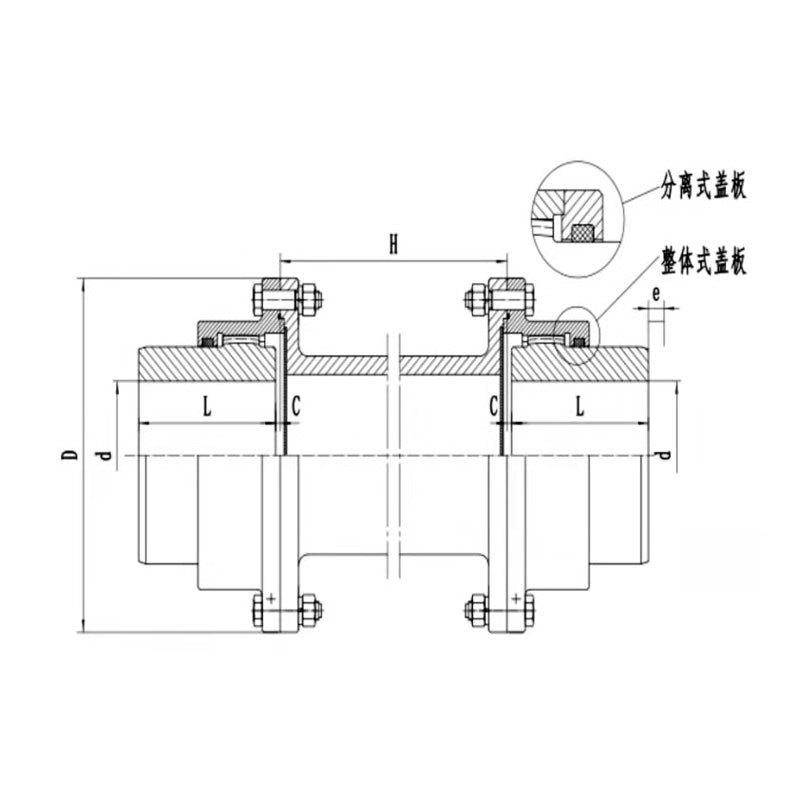

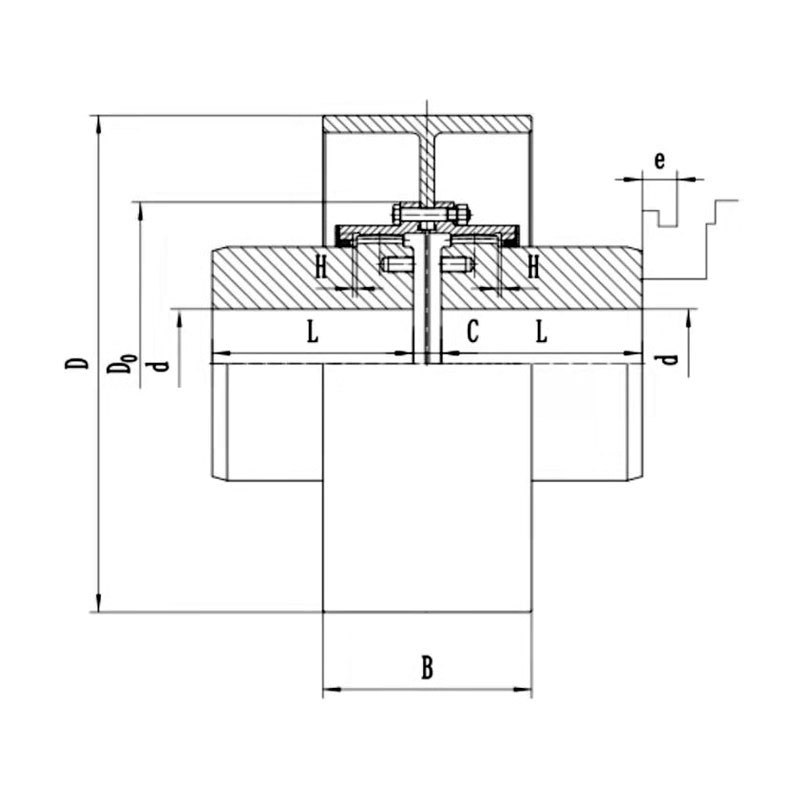

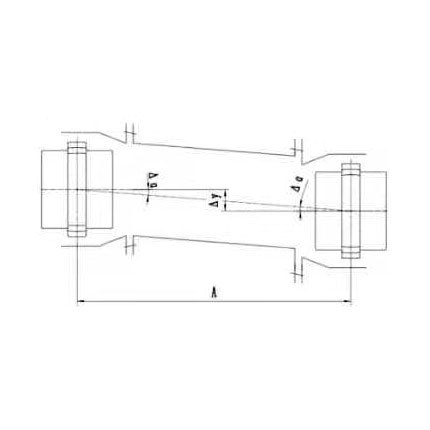

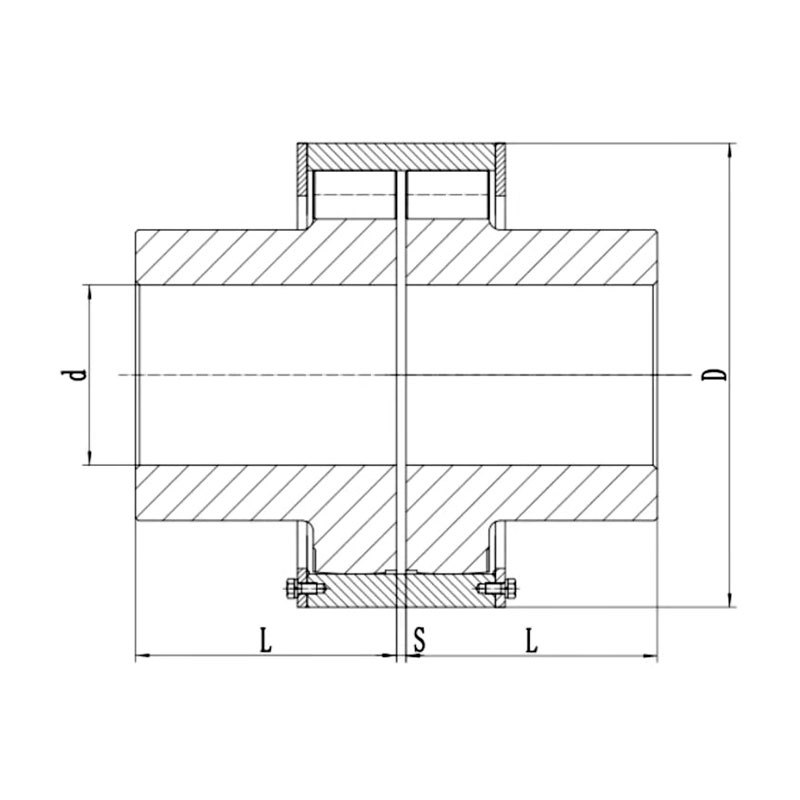

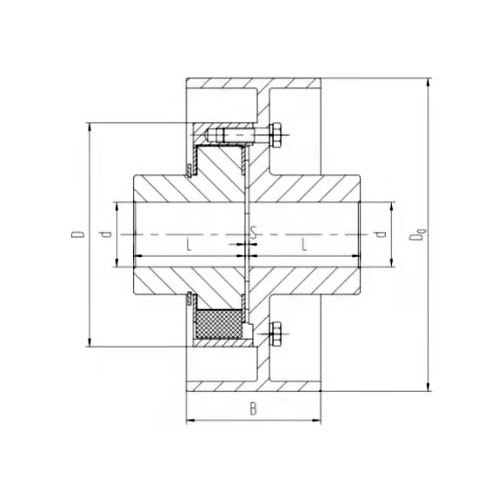

Its structural configuration is shown in Figure 2.4, and the technical parameters and main dimensions are listed in Table 2-4 and Table 2-5.

Figure 2.4G-type diaphragm coupling

Table 2-4G: Main Dimensions of Diaphragm Couplings

| Model | A 0 | A | bmax | L | Emin | ||

| 6090 | 125 | 95 | 65 | 65 | 160 | ||

| 6120 | 155 | 122 | 85 | 85 | 180 | ||

| 6150 | 188 | 150 | 100 | 100 | 200 | ||

| 6170 | 212 | 170 | 115 | 115 | 230 | ||

| 6190 | 233 | 190 | 130 | 130 | 260 | ||

| 6210 | 260 | 210 | 145 | 140 | 265 | ||

| 6240 | 8240 | 295 | 240 | 165 | 160 | 280 | |

| 6260 | 8260 | 310 | 265 | 180 | 180 | 310 | |

| 6280 | 8280 | 334 | 280 | 195 | 190 | 310 | |

| 6310 | 8310 | 1310 | 362 | 310 | 215 | 215 | 345 |

| 8340 | 1340 | 392 | 340 | 240 | 240 | 390 | |

| 8370 | 1370 | 430 | 370 | 255 | 255 | 420 | |

| 8400 | 1400 | 466 | 400 | 280 | 275 | 430 | |

| 8430 | 1430 | 496 | 430 | 300 | 295 | 480 | |

| 8460 | 1460 | 531 | 460 | 320 | 315 | 500 | |

| 8490 | 1490 | 562 | 490 | 345 | 335 | 530 | |

| 1520 | 594 | 516 | 360 | 355 | 580 | ||

| 1560 | 638 | 560 | 395 | 380 | 580 | ||

| 1600 | 680 | 600 | 420 | 410 | 590 | ||

Table 2—Technical Parameters of 5G Type Diaphragm Coupling

| Model Size |

Permissible Torque Coefficient (kW/rpm) |

Nominal torque Mr. (KNm) |

Peak torque (KNm) |

Maximum rotational speed (rpm) |

The entire coupling | Intermediate pipe per meter | Allow axial displacement | Allow angular misalignment (Degree) |

|||||

| Weight (kg) |

Moment of inertia (kg·m²) |

Torsional stiffness TS (Nm/rad) |

Weight (kg) |

Moment of inertia (kg·m²) |

Torsional stiffness You (Nm/rad) |

Coupling (mm) |

Steering force (N) |

||||||

| 6090 | 0.05 | 0.5 | 0.62 | 32000 | 6 | 0.01 | 0.09 | 3.30 | 0.003 | 0.03 | 1.2 | 480 | 0.375 |

| 6120 | 0.11 | 1.1 | 1.37 | 26000 | 12 | 0.03 | 0.16 | 4.13 | 0.004 | 0.04 | 1.8 | 790 | 0.375 |

| 6150 | 0.17 | 1.7 | 2.12 | 20000 | 22 | 0.08 | 0.33 | 5.50 | 0.011 | 0.12 | 2.1 | 1000 | 0.375 |

| 6170 | 0.28 | 2.8 | 3.50 | 18300 | 32 | 0.15 | 0.62 | 6.14 | 0.015 | 0.16 | 2.9 | 1500 | 0.375 |

| 6190 | 0.48 | 4.8 | 6.00 | 17000 | 45 | 0.28 | 1.06 | 9.85 | 0.032 | 0.33 | 3.1 | 1800 | 0.375 |

| 6210 | 0.78 | 7.8 | 9.75 | 15000 | 56 | 0.41 | 1.56 | 12.70 | 0.052 | 0.55 | 3.5 | 1900 | 0.375 |

| 6240 | 1.20 | 12 | 15.00 | 13500 | 78 | 0.75 | 2.85 | 15.92 | 0.090 | 0.92 | 4.2 | 2600 | 0.375 |

| 6260 | 1.50 | 15 | 18.75 | 12500 | 105 | 1.35 | 3.64 | 18.56 | 0.180 | 1.90 | 4.6 | 2900 | 0.375 |

| 6280 | 1.75 | 17.5 | 21.87 | 12000 | 124 | 1.80 | 4.60 | 22.00 | 0.290 | 2.92 | 5.0 | 3300 | 0.375 |

| 6310 | 2.36 | 23.6 | 29.50 | 11000 | 162 | 2.80 | 6.70 | 29.94 | 0.300 | 3.05 | 5.5 | 4000 | 0.375 |

| 8240 | 1.5 | 15.0 | 18.75 | 13500 | 78 | 0.76 | 3.50 | 15.72 | 0.090 | 0.92 | 2.5 | 3000 | 0.250 |

| 8260 | 1.75 | 17.5 | 21.87 | 12500 | 105 | 1.35 | 3.64 | 18.56 | 0.180 | 1.90 | 2.8 | 3500 | 0.250 |

| 8280 | 2.68 | 26.8 | 33.50 | 12000 | 124 | 1.82 | 5.85 | 22.00 | 0.290 | 2.92 | 3.1 | 4000 | 0.250 |

| 8310 | 2.96 | 29.6 | 37.00 | 11000 | 162 | 2.83 | 8.40 | 29.94 | 0.300 | 3.05 | 3.8 | 4900 | 0.250 |

| 8340 | 3.75 | 37.5 | 46.87 | 9800 | 221 | 4.65 | 13.90 | 38.28 | 0.460 | 4.63 | 4.2 | 7000 | 0.250 |

| 8370 | 4.70 | 47.0 | 58.75 | 9100 | 284 | 6.65 | 21.00 | 47.50 | 0.690 | 6.95 | 4.6 | 8900 | 0.250 |

| 8400 | 6.30 | 63.0 | 78.75 | 8400 | 357 | 9.70 | 27.00 | 55.60 | 0.950 | 9.60 | 5.1 | 10000 | 0.250 |

| 8430 | 8.00 | 80.0 | 100.00 | 7800 | 430 | 13.25 | 33.00 | 63.80 | 1.350 | 13.90 | 5.9 | 12000 | 0.250 |

| 8460 | 8.50 | 85.0 | 106.25 | 7400 | 526 | 19.00 | 38.00 | 75.62 | 1.750 | 18.00 | 6.3 | 14000 | 0.250 |

| 8490 | 10.50 | 105.0 | 131.25 | 6900 | 634 | 25.70 | 46.00 | 80.60 | 2.100 | 22.00 | 6.8 | 15000 | 0.250 |

| 1310 | 3.92 | 39.2 | 49.85 | 11000 | 163 | 2.85 | 10.10 | 29.94 | 0.300 | 3.05 | 2.4 | 8000 | 0.165 |

| 1340 | 4.87 | 48.7 | 61.90 | 9800 | 222 | 4.67 | 17.40 | 38.28 | 0.460 | 4.63 | 2.8 | 15000 | 0.165 |

| 1370 | 6.25 | 62.5 | 79.35 | 9100 | 289 | 6.68 | 27.10 | 47.50 | 0.690 | 6.95 | 3.2 | 16500 | 0.165 |

| 1400 | 8.40 | 84.0 | 106.65 | 8400 | 359 | 9.78 | 35.00 | 55.60 | 0.950 | 9.60 | 3.6 | 19000 | 0.165 |

| 1430 | 10.65 | 106.5 | 135.50 | 7800 | 435 | 13.34 | 42.80 | 63.80 | 1.350 | 13.90 | 4.0 | 21000 | 0.165 |

| 1460 | 11.3 | 113.0 | 143.50 | 7400 | 528 | 19.85 | 48.60 | 75.60 | 1.750 | 18.00 | 4.3 | 22000 | 0.165 |

| 1490 | 14.00 | 140.0 | 177.80 | 6900 | 637 | 26.82 | 59.80 | 80.60 | 2.100 | 22.00 | 4.7 | 23000 | 0.165 |

| 1520 | 16.50 | 165.0 | 206.25 | 6500 | 814 | 39.00 | 90.00 | 86.00 | 2.550 | 26.00 | 5.0 | 27000 | 0.165 |

| 1560 | 18.30 | 183.0 | 228.75 | 6100 | 940 | 52.00 | 102.00 | 93.50 | 3.300 | 34.50 | 5.7 | 30000 | 0.165 |

| 1600 | 26.00 | 260.0 | 325.00 | 5900 | 1200 | 78.00 | 118.00 | 142.00 | 5.200 | 54.71 | 6.2 | 35000 | 0.165 |

Note:

1. The parameters in the technical data sheet are all based on the dimensions provided in the size chart.

2. Users often request changes to the shaft-to-shaft distance E; the parameters of the deformed coupling can be easily calculated based on the data provided in the table.

T = Torsional stiffness

E = New spindle center distance

3. For other changes, please contact Schenker’s Engineering Department.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products