LMS-type梅花-shaped elastic coupling

Category

Contact Information

Detailed introduction

Product Features

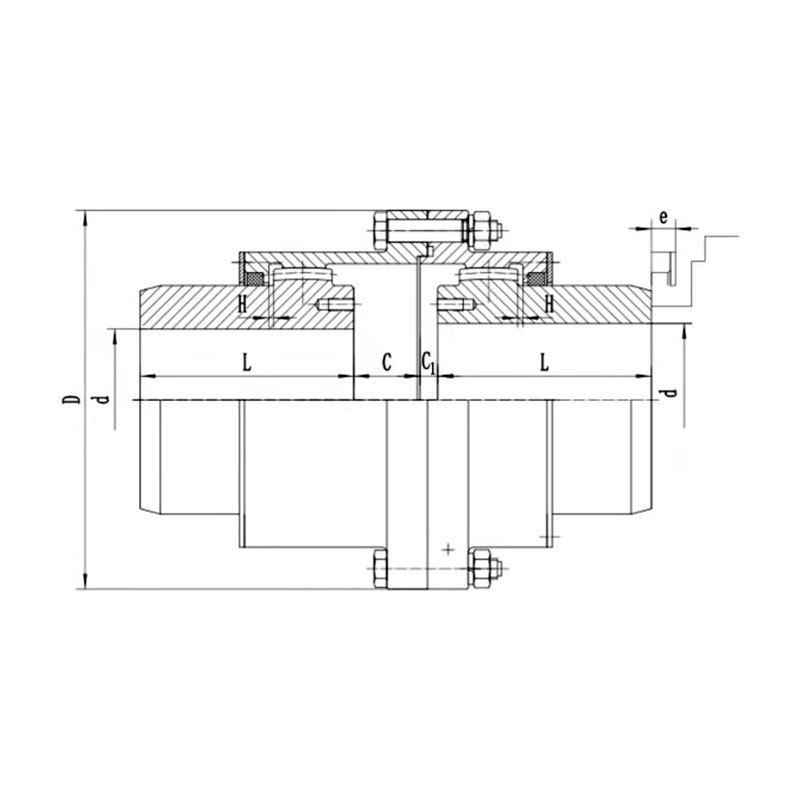

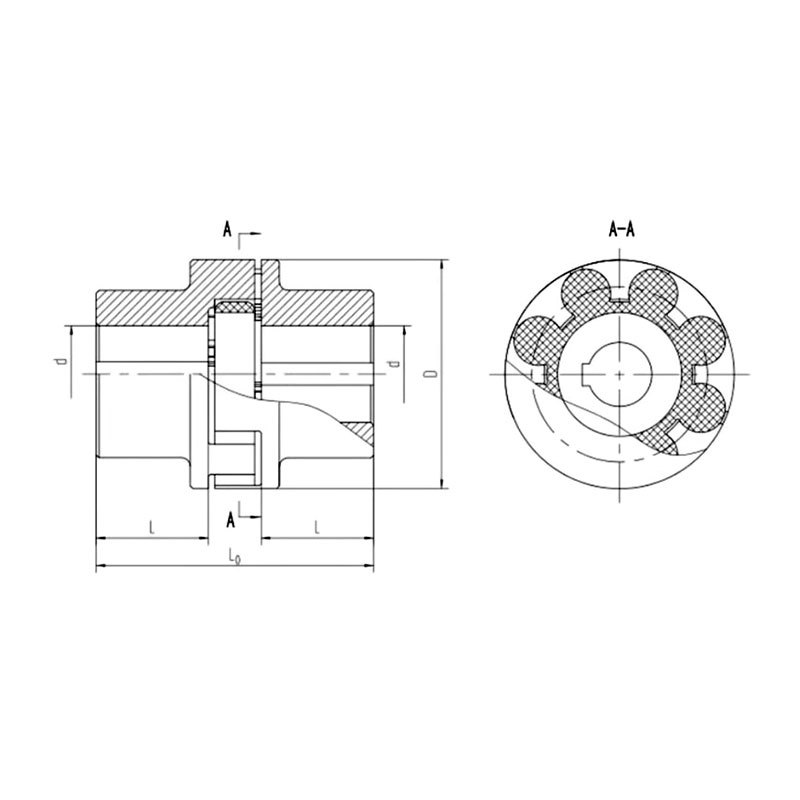

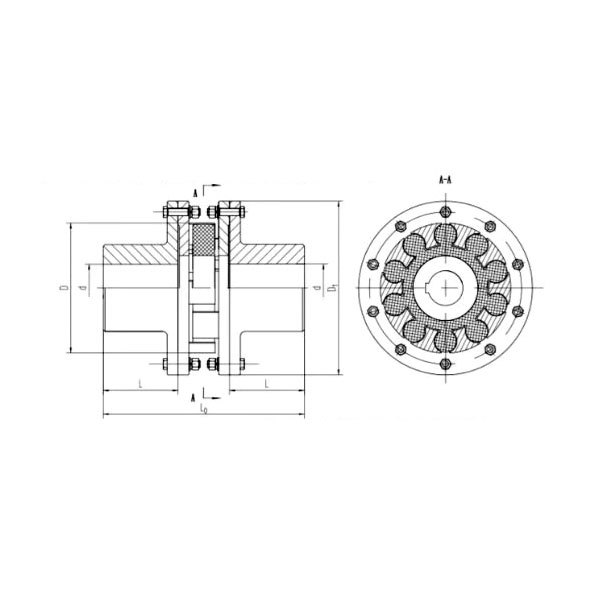

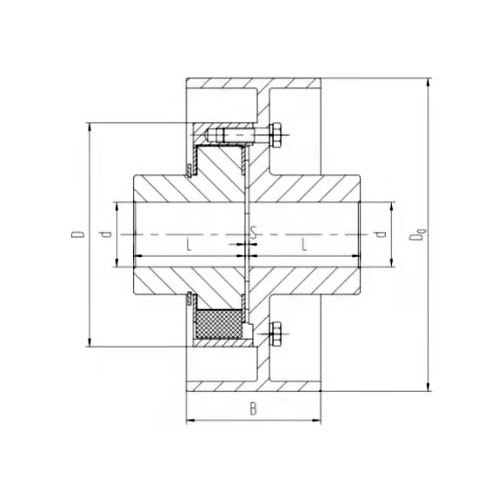

The梅花-shaped elastic coupling consists of two identical half-couplings with claw-shaped protrusions and an elastic element. The梅花-shaped elastic element is placed between the claws of the two half-couplings, thereby achieving the connection between them.

It features compensation for relative misalignment between the two shafts, vibration damping, shock absorption, a small radial dimension, a simple structure, no lubrication required, relatively high load-carrying capacity, and easy maintenance.

Application scenarios

Suitable for applications involving the connection of two coaxial shafts, frequent starts and stops, reversible operation, medium-to-low speeds, small-to-medium power transmission systems, and operating environments that demand high reliability.

LMS-type梅花-shaped elastic coupling

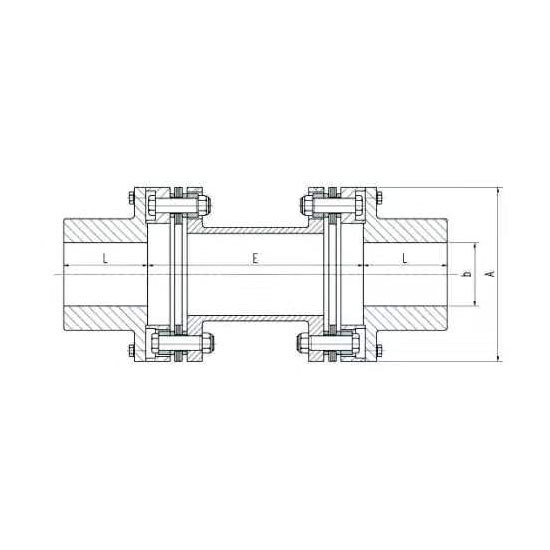

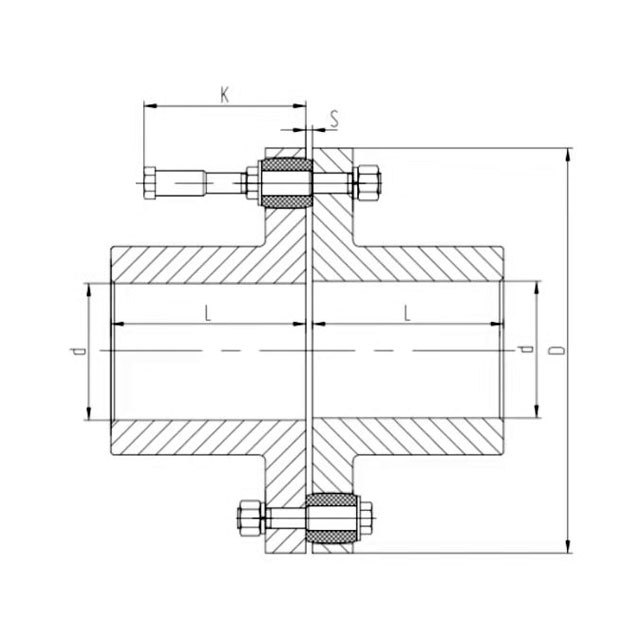

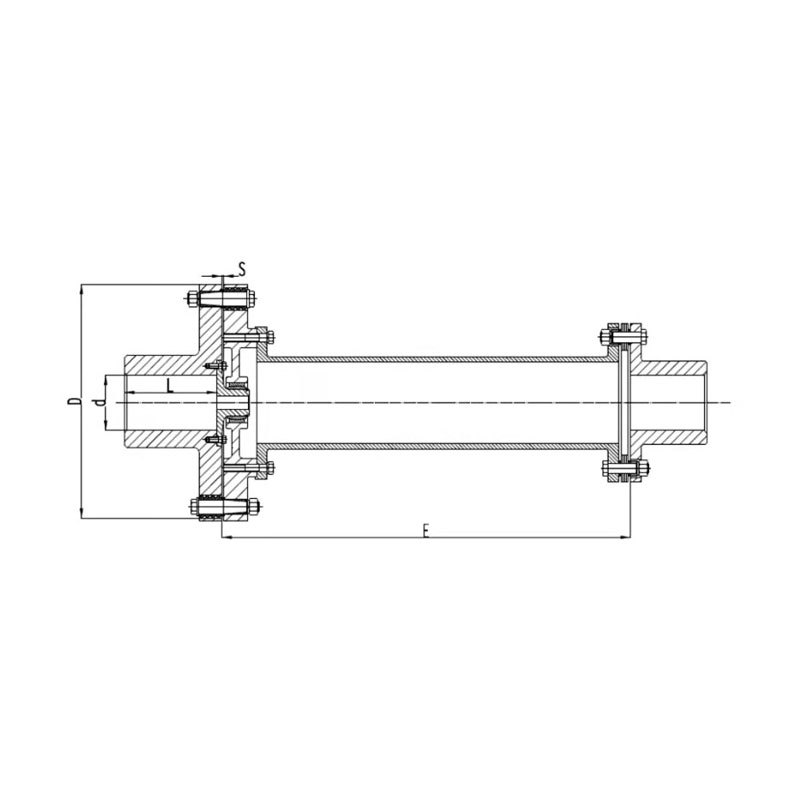

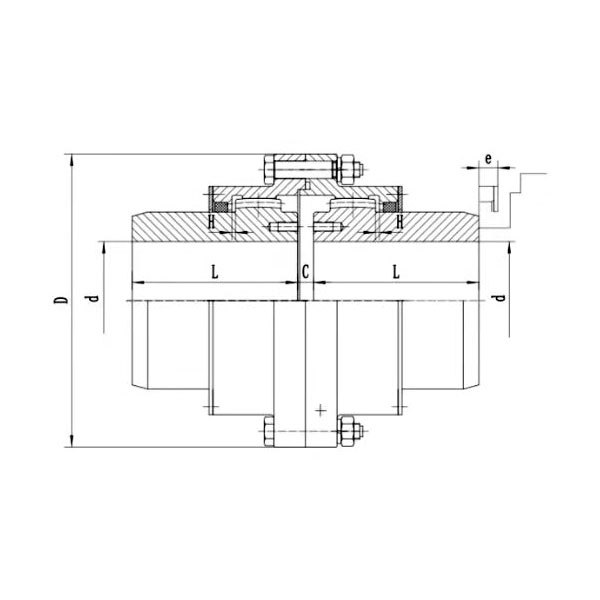

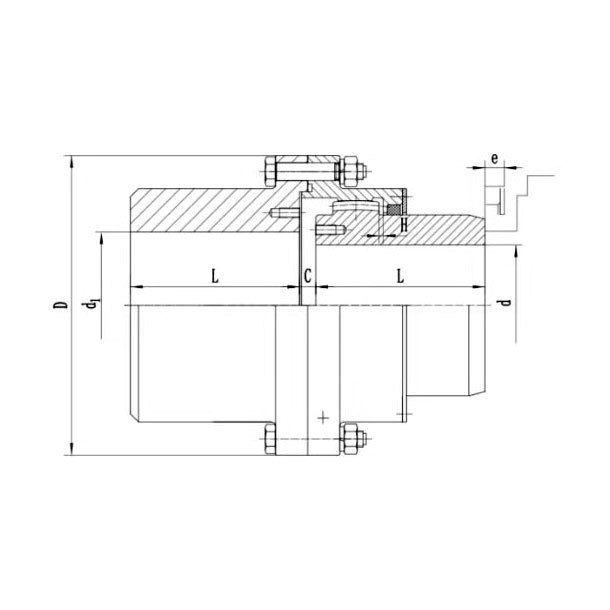

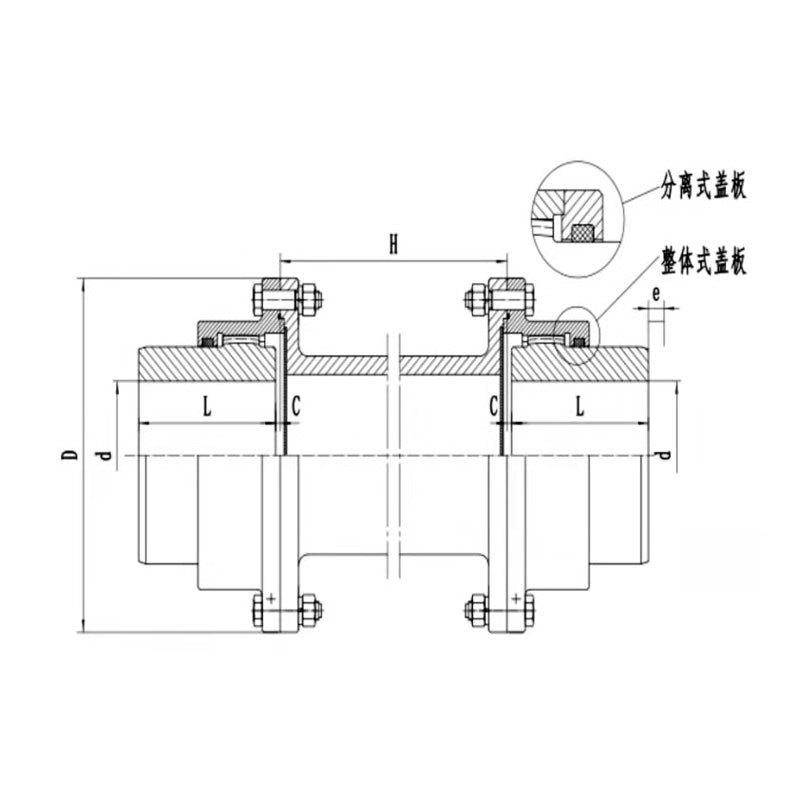

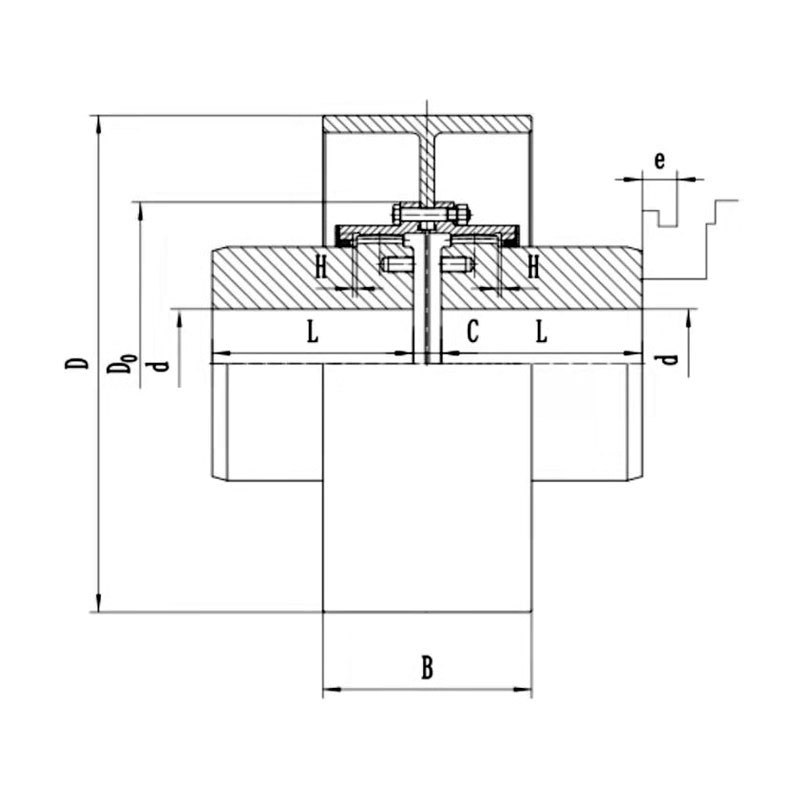

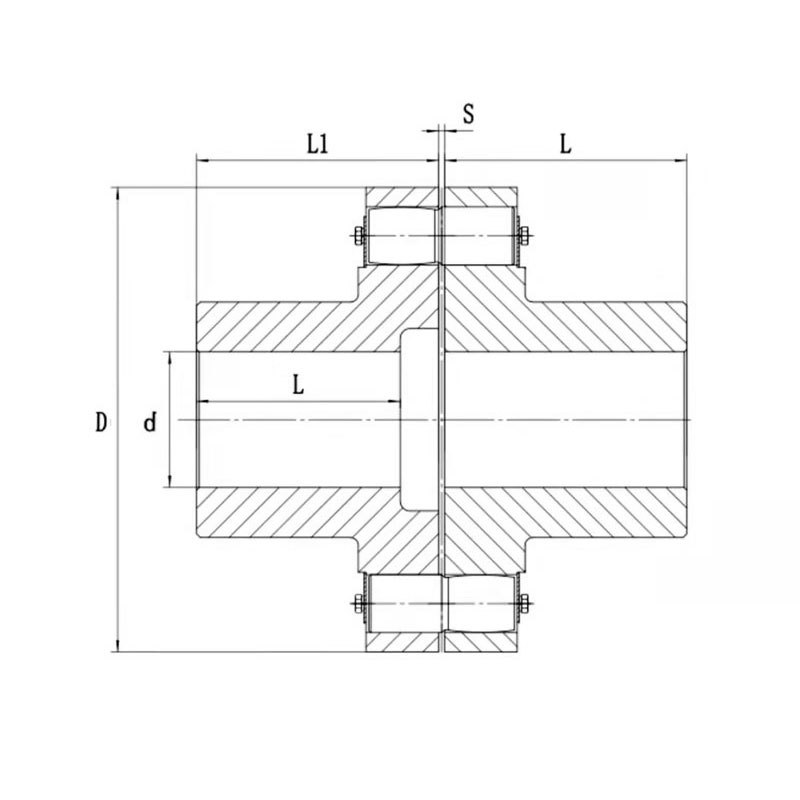

The LMS (double-flange type) plum-blossom-shaped elastic coupling allows replacement of the elastic element without axially moving the coupling. Its structural configuration is shown in Figure 6.2, and its technical parameters and main dimensions are listed in Table 6-2.

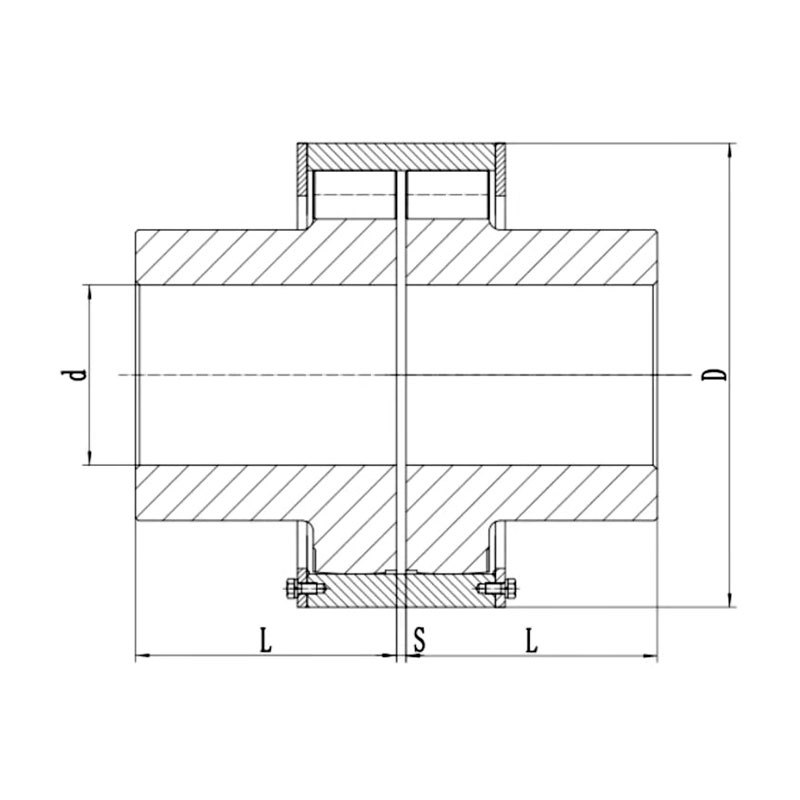

Figure 6.2 LMS-type梅花-shaped elastic coupling

Table 6-2: Technical Parameters and Main Dimensions of the LMS Type Plum Blossom Elastic Coupling

| Model | Nominal torque Tn N · m |

Permissible rotational speed [n] r/min |

Shaft hole diameter d mm |

L/m | L 0/m | D/m | D 1/m | Elastic component Model |

Quality Kg |

Moment of inertia Kg·m² |

Allowable maximum installation error | Maximum operating compensation amount | Axial clearance ±10% mm |

|||

| Elastic component hardness | Radial mm |

Angular. | Radial mm |

Angular. | ||||||||||||

| a(HA) | b(HD) | |||||||||||||||

| 80 ± 5 | 60 ± 5 | |||||||||||||||

| LMS1 | 25 | 45 | 8500 | 12, 14, 16, 18, 19, 20, 22, 24, 25 | 35 | 98 | 50 | 90 | MT1 -a-b | 1.325 | 0.0013 | 0.2 | 1 | 0.5 | 2 | 1.2 |

| LMS2 | 50 | 100 | 7600 | 16, 18, 17, 20, 22, 24, 28, 28, 30 | 38 | 108 | 60 | 100 | MT2 -a-b | 1.736 | 0.0021 | 0.3 | 0.6 | 1.3 | ||

| LMS3 | 100 | 200 | 6900 | 20, 22, 24, 25, 28, 30, 32 | 40 | 117 | 70 | 110 | MT3 -a-b | 2.33 | 0.0034 | 0.4 | 0.8 | 1.5 | ||

| LMS4 | 140 | 280 | 6200 | 22, 24, 25, 28, 30, 32, 35, 38, 40 | 45 | 130 | 85 | 125 | NT4 -a-b | 3.375 | 0.0064 | 2 | ||||

| LMS5 | 350 | 400 | 5000 | 25, 28, 30, 32, 35, 38, 40, 42, 45 | 50 | 150 | 105 | 150 | MT5 -a-b | 6.067 | 0.0175 | 2.5 | ||||

| LMS6 | 400 | 710 | 4100 | 30, 32, 35, 38, 40, 42, 45, 48 | 55 | 167 | 125 | 185 | MT6-a-b | 10.466 | 0.044 | 0.5 | 0.7 | 1 | 1.5 | 3 |

| LMS7 | 630 | 1120 | 3700 | 35*, 38*, 40*, 42*, 45, 48, 50, 55 | 60 | 185 | 145 | 205 | MT7 -a-b | 14.233 | 0.0739 | |||||

| LMS8 | 1120 | 2240 | 3100 | 45*, 48*, 50, 55, 56, 60, 63, 65 | 70 | 209 | 170 | 240 | MT8 -a-b | 21.16 | 0.149 | |||||

| LMS9 | 1800 | 3550 | 2800 | 50*, 55*, 56*, 60, 63, 65, 70, 71, 75, 80 | 80 | 240 | 200 | 270 | MT9 -a-b | 30.699 | 0.275 | 0.7 | 1.5 | 3.5 | ||

| LMS10 | 2800 | 5600 | 2500 | 60*, 63*, 65*, 70, 71, 75, 80, 85, 90, 95, 100 | 90 | 268 | 230 | 305 | MT10 -a-b | 44.547 | 0.526 | 0.5 | 1 | 4 | ||

| LMS11 | 4500 | 9000 | 2200 | 70*, 71*, 75*, 80*, 85*, 90, 95, 100, 110, 120 | 100 | 308 | 260 | 350 | MT11-a-b | 70.72 | 1.136 | 4.5 | ||||

| LMS12 | 6300 | 12500 | 1900 | 80*, 85*, 90*, 95*, 100, 110, 120, 125, 130 | 115 | 345 | 300 | 400 | MT12 -a-b | 99.544 | 1.999 | 0.8 | 1.8 | 5 | ||

| LMS13 | 11200 | 20000 | 1600 | 90*, 95*, 100*, 110*, 120*, 125*, 130, 140, 150 | 125 | 373 | 360 | 460 | MT13 -a-b | 137.53 | 3.67 | |||||

| LMS14 | 12500 | 25000 | 1500 | 100*, 110*, 120*, 125*, 130*, 140*, 150, 160 | 135 | 383 | 400 | 500 | MT14 -a-b | 165.25 | 5.158 | |||||

Note: 1. The values for mass and moment of inertia are approximate, calculated based on cast steel as the material, the recommended L value, and the maximum shaft bore.

2. The shaft hole diameter marked with an asterisk can be used for Z-type shaft holes; if the shaft hole length is specified according to GB/T3852, please consult with our factory.

3. a and b are hardness codes for two types of elastic materials.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products