Lz-type Elastic Pin-and-Tooth Coupling

Category

Contact Information

Detailed introduction

Product Features

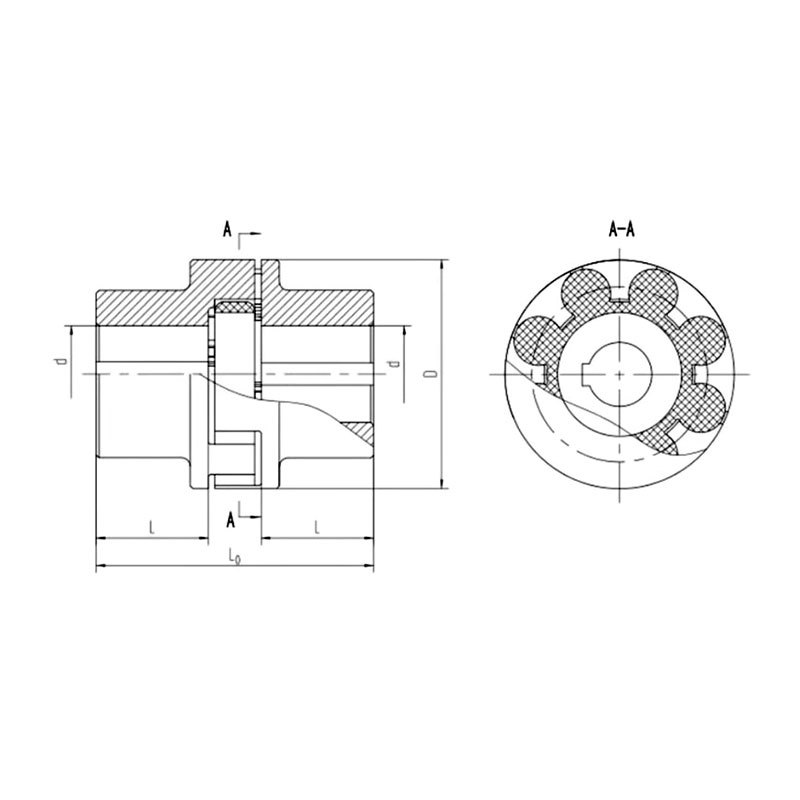

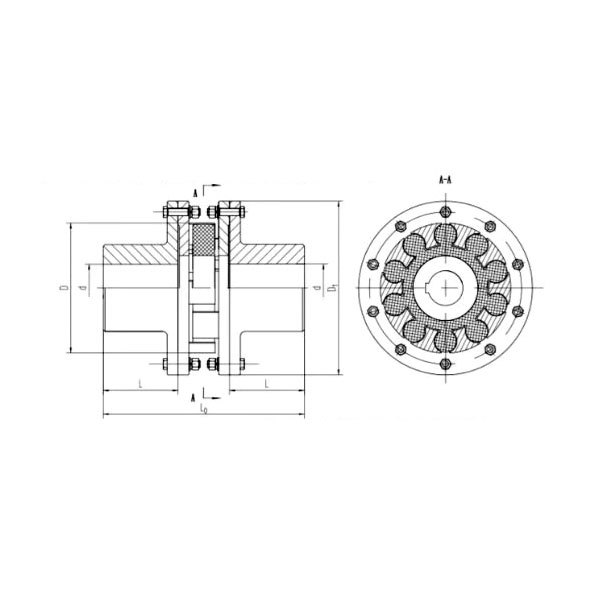

The elastic pin-type gear coupling uses several non-metallic pins inserted into mating holes between the two halves of the coupling and the inner surface of the outer ring. Torque is transmitted through these pins, thereby connecting the two halves of the coupling. This coupling features the following characteristics:

It features high torque transmission, small size, light weight, easy maintenance, long service life, and requires no lubrication. However, this coupling has poor shock-absorbing performance and generates relatively high noise levels.

Application scenarios

The elastic pin-type gear coupling is suitable for transmission shaft systems with coaxial alignment and utilizes the shear strength of nylon rods in their longitudinal section. It can transmit large torques ranging from 0.112 to 2800 kN·m. Its operating temperature range is -20 to 70℃, and it can partially replace gear couplings. This coupling features a certain degree of axial misalignment compensation and generally good vibration-damping performance.

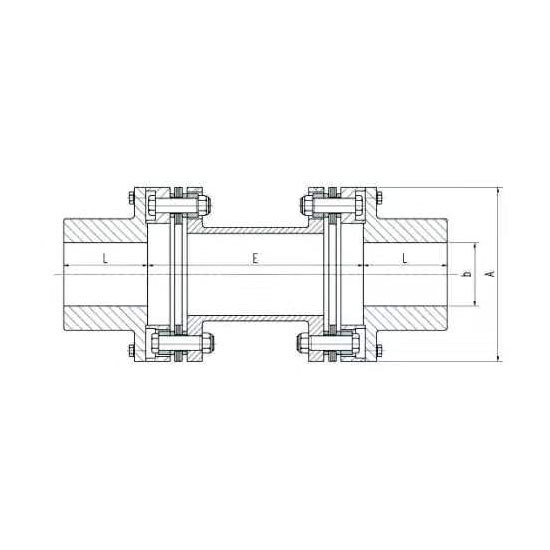

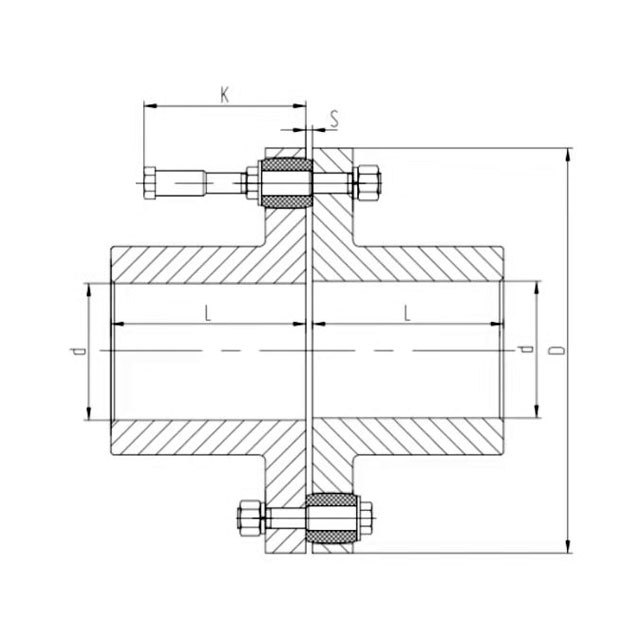

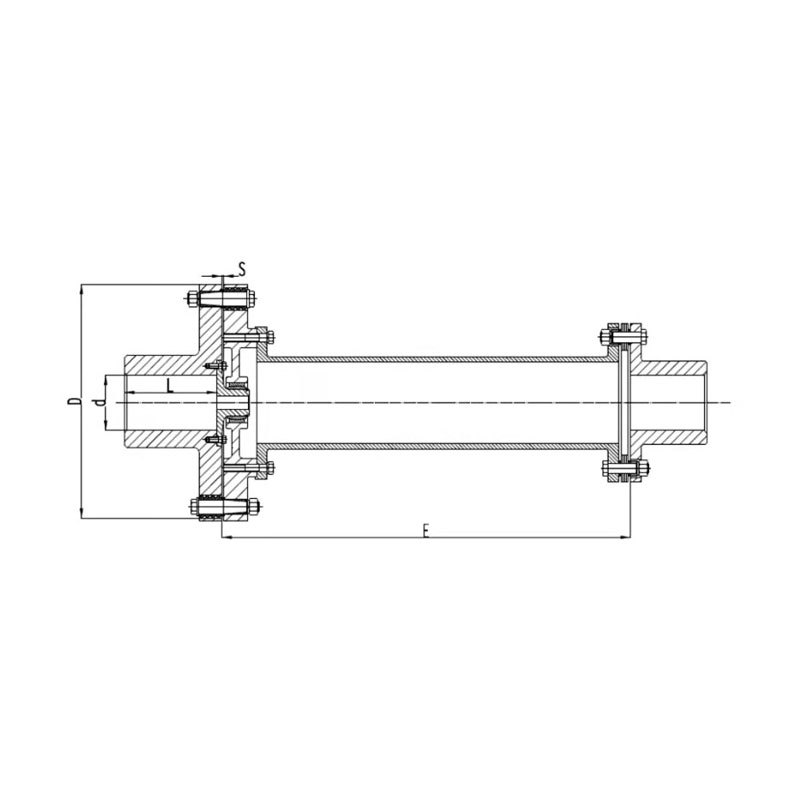

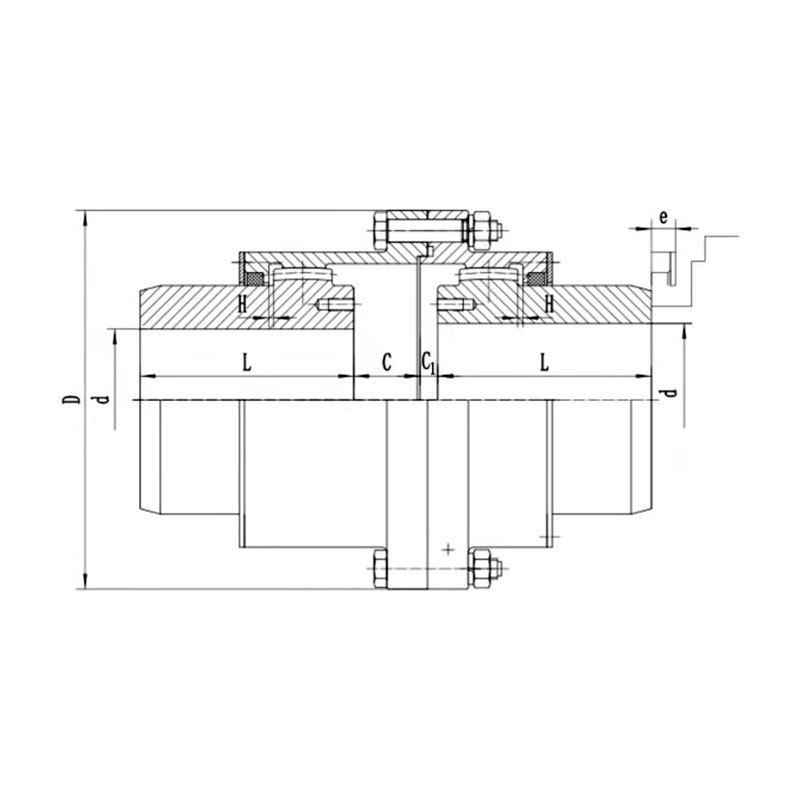

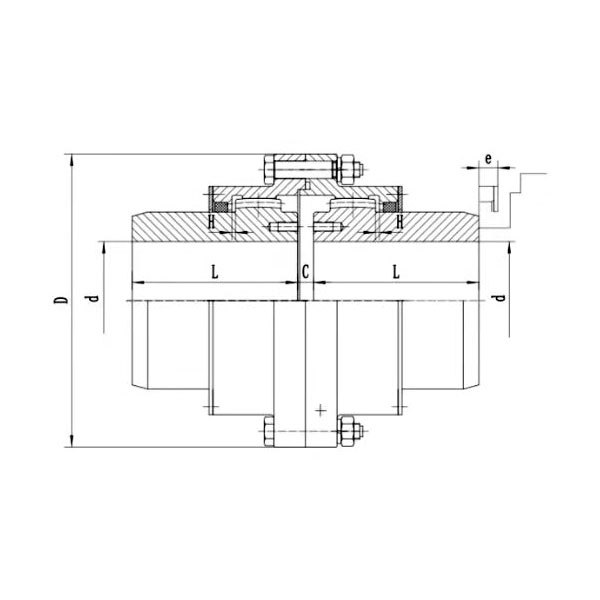

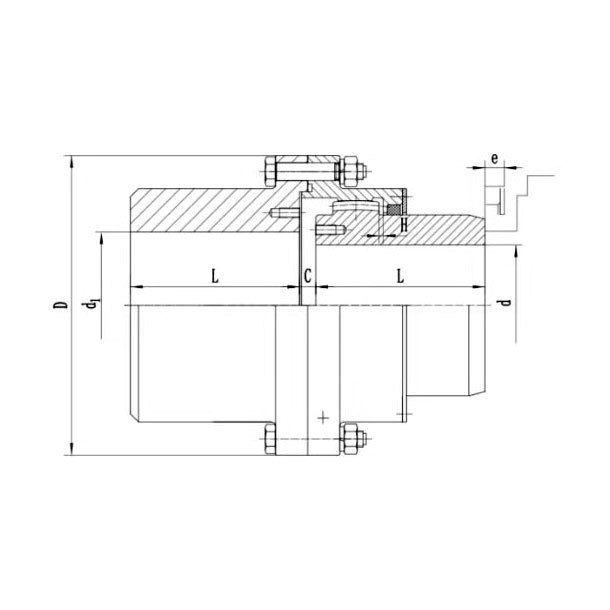

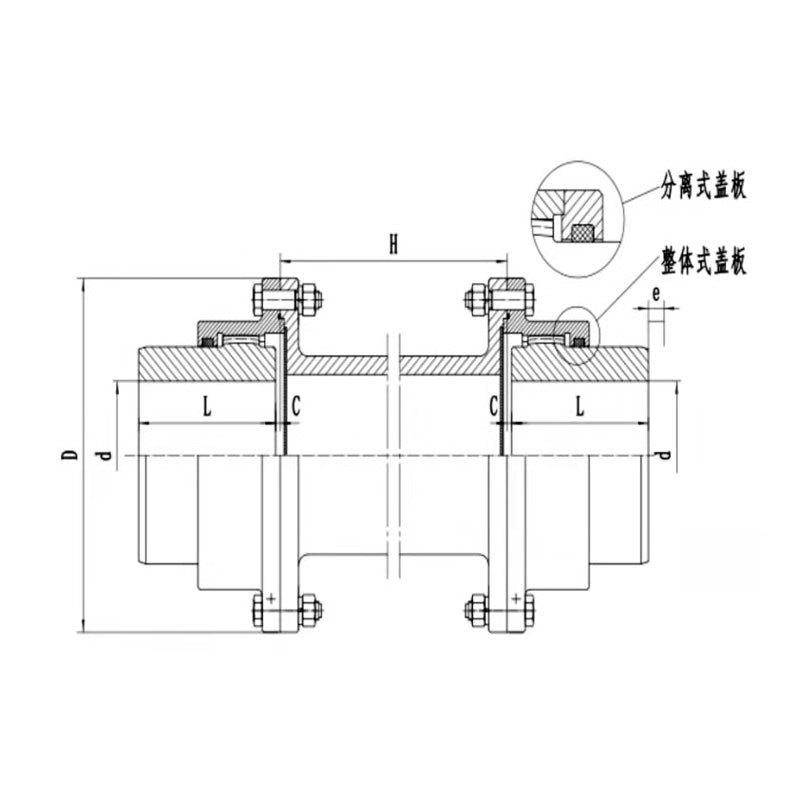

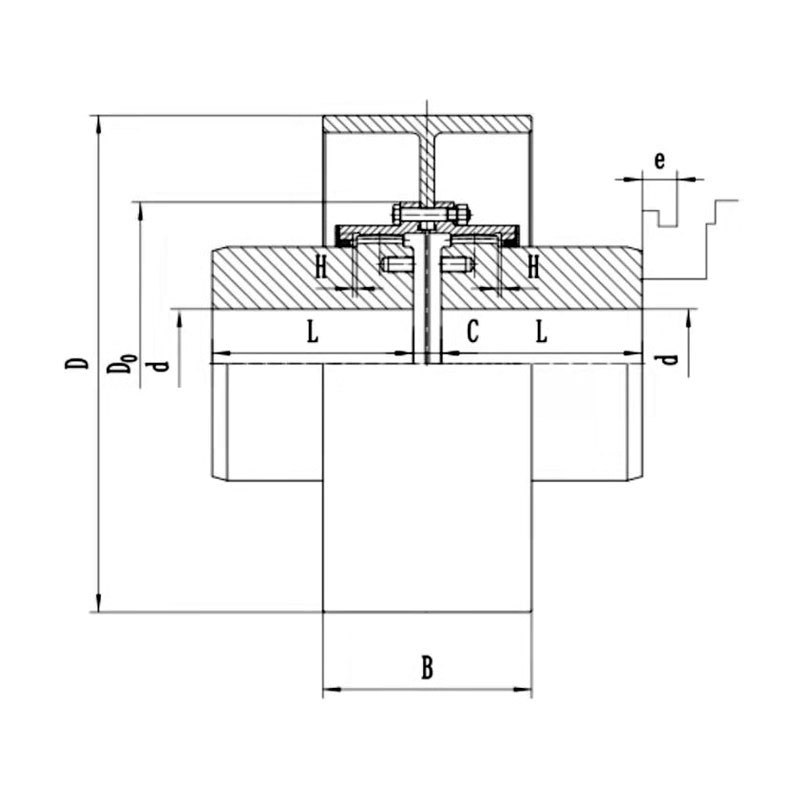

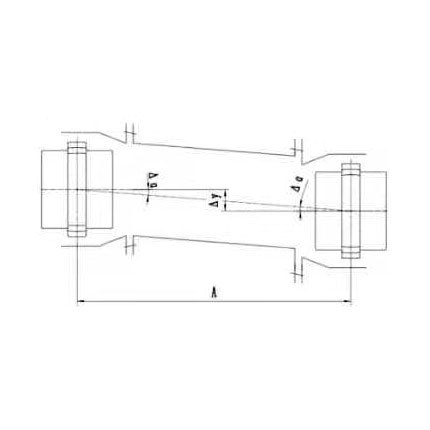

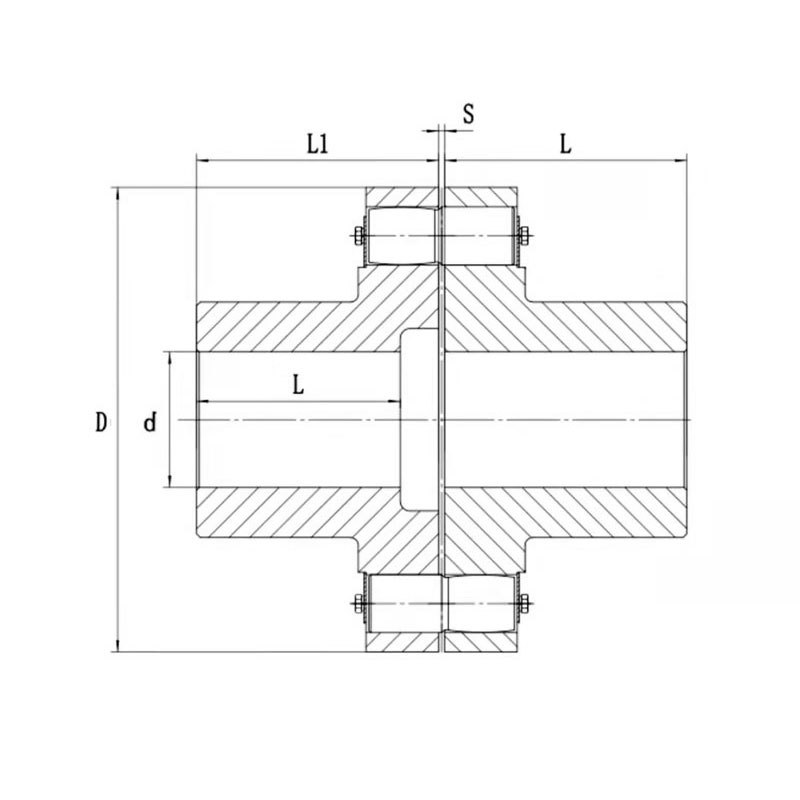

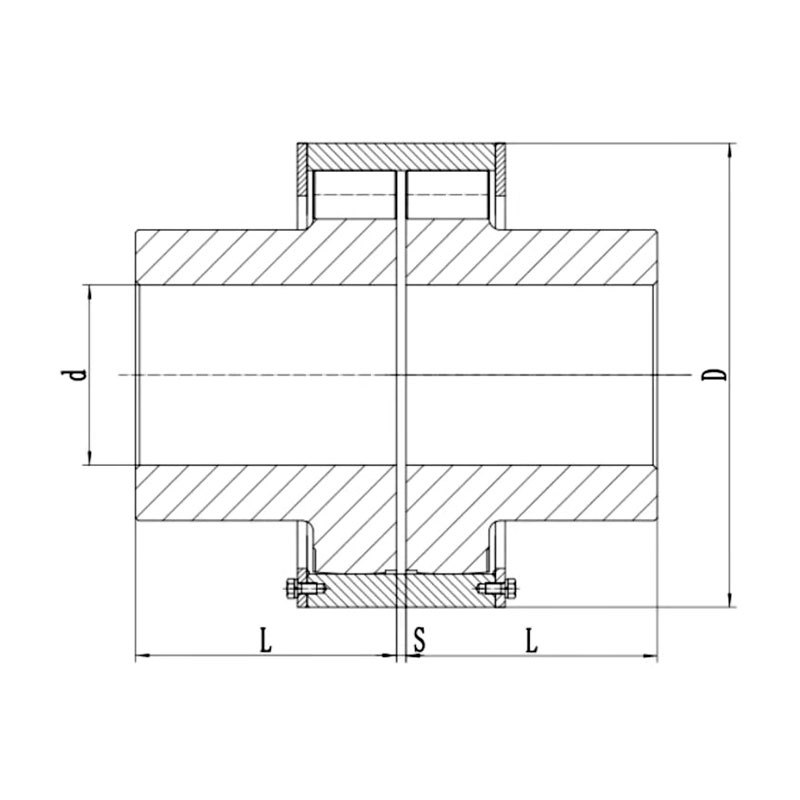

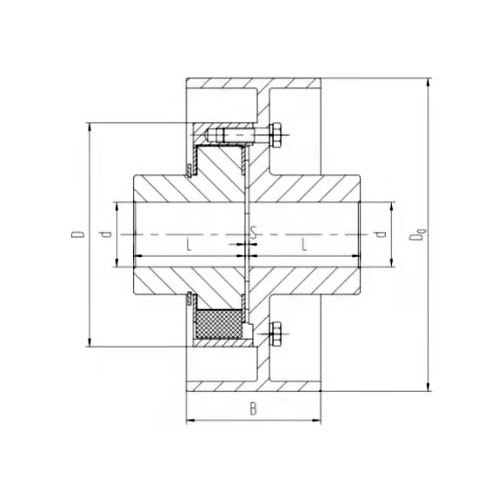

Its structural configuration is shown in Figure 8.1, and the technical parameters and main dimensions are listed in Table 8-1.

Figure 8.1 LZ-type elastic pin-and-tooth coupling

Table 8-1: Technical Parameters and Main Dimensions of LZZ Type Elastic Pin-and-Tooth Coupling

| Model | Nominal torque Mr. kN·m |

Permissible Rotational Speed [n] revolutions per minute |

Shaft hole diameter d |

Shaft hole length | D | S | Moment of inertia kg · m² |

Weight kilogram |

Permissible compensation amount | |||

| Y-shaped | J 1 Type | |||||||||||

| L | Radial mm |

Axial mm |

Angular direction 。 |

|||||||||

| mm | ||||||||||||

| LZ1 | 0.112 | 5000 | 12~24 | 27~52 | 76 | 2.5 | 0.001 | 1.67 | 0.3 | ±1.5 | 0.5 | |

| LZ2 | 0.25 | 5000 | 16~32 | 44~82 | 90 | 2.5 | 0.003 | 3.00 | ||||

| LZ3 | 0.63 | 4500 | 25~42 | 44~112 | 118 | 3.0 | 0.012 | 7.31 | ||||

| LZ4 | 1.8 | 4200 | 40~60 | 84~142 | 158 | 4 | 0.045 | 16.20 | 0.4 | |||

| LZ5 | 4.5 | 4000 | 50~80 | 84~172 | 192 | 4 | 0.108 | 27.02 | ||||

| LZ6 | 8 | 3300 | 60~95 | 107~172 | 230 | 5 | 0.242 | 40.89 | ||||

| LZ7 | 11.2 | 2900 | 70~110 | 107~212 | 260 | 5 | 0.443 | 59.60 | ||||

| LZ8 | 18 | 2500 | 80~130 | 132~252 | 300 | 6 | 0.908 | 94.67 | 0.6 | ±2.5 | ||

| LZ9 | 25 | 2300 | 90~150 | 132~252 | 335 | 7 | 1.733 | 138.1 | ||||

| LZ10 | 31.5 | 2100 | 100~170 | 167~302 | 355 | 8 | 2.422 | 169.3 | ||||

| LZ11 | 40 | 2000 | 110~180 | 167~302 | 380 | 8 | 3.369 | 203.1 | ||||

| LZ12 | 63 | 1700 | 130~200 | 202~352 | 445 | 8 | 6.524 | 296.6 | ||||

| LZ13 | 100 | 1500 | 150~240 | 202~410 | 515 | 8 | 14.19 | 469.2 | ||||

| LZ14 | 125 | 1400 | 170~260 | 242~410 | 560 | 8 | 21.67 | 621.7 | 1 | |||

| LZ15 | 160 | 1300 | 190~300 | 282~470 | 590 | 10 | 29.52 | 730.5 | ||||

| LZ16 | 250 | 1000 | 220~340 | 282~550 | 695 | 10 | 62.47 | 1144 | ||||

| LZ17 | 355 | 950 | 240~380 | 330~550 | 770 | 10 | 106.0 | 1557 | ||||

| LZ18 | 450 | 850 | 250~420 | 330~650 | 860 | 13 | 175.4 | 2062 | ±5 | |||

| LZ19 | 630 | 750 | 280~450 | 380~650 | 970 | 14 | 323.2 | 3068 | ||||

| LZ20 | 1120 | 650 | 320~500 | 380~650 | 1160 | 15 | 669.4 | 4715 | ||||

| LZ21 | 1800 | 530 | 380~630 | 450~800 | 1440 | 18 | 1880 | 8599 | ||||

| LZ22 | 2240 | 500 | 420~750 | 540~800 | 1520 | 19 | 2596 | 9473 | 1.5 | |||

| LZ23 | 2800 | 460 | 480~850 | 540~880 | 1640 | 20 | 3982 | 12095 | ||||

Note: 1. The weight and moment of inertia are calculated based on the Y/J1 shaft-hole combination type and the minimum shaft-hole dimension.

2. The short-term overload shall not exceed twice the nominal torque Tn.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products

T-type and D-type diaphragm couplings

NUP New Elastic Sleeve Pin Coupling

NUPEX Combination Flexible Coupling

GCLD Type Spherical Tooth Coupling

GIICL-type drum-type gear coupling

GIICLZ-type drum-type gear coupling

WGT Type Drum-Type Gear Coupling

NGCL Type Spherical Tooth Coupling

Compensating capacity for relative displacement between the two shafts of a drum-type gear coupling

LM-type梅花-shaped elastic coupling

LMS-type梅花-shaped elastic coupling

Lz-type Elastic Pin-and-Tooth Coupling

LZZ Type Elastic Pin-and-Block Coupling with Brake Wheel

Shenyang Shenke Power Machinery Co,. Ltd.

Address: No. 34 Jia, Kaifa Avenue, Tiexi Economic and Technological Development Zone, Shenyang

Email:sincflex@vip.163.com

Phone:+86 24 25830257

Mobile phone:+86 15940017261

Fax: +86 24 25308993

WeChat contact