Lx Elastic Pin Coupling

Category

Contact Information

Detailed introduction

Product Features

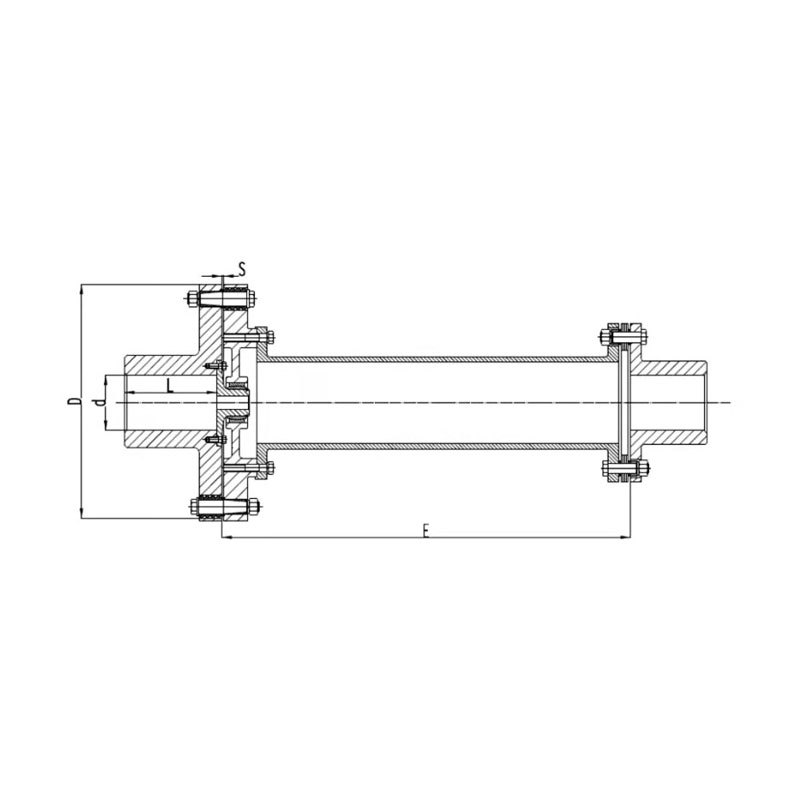

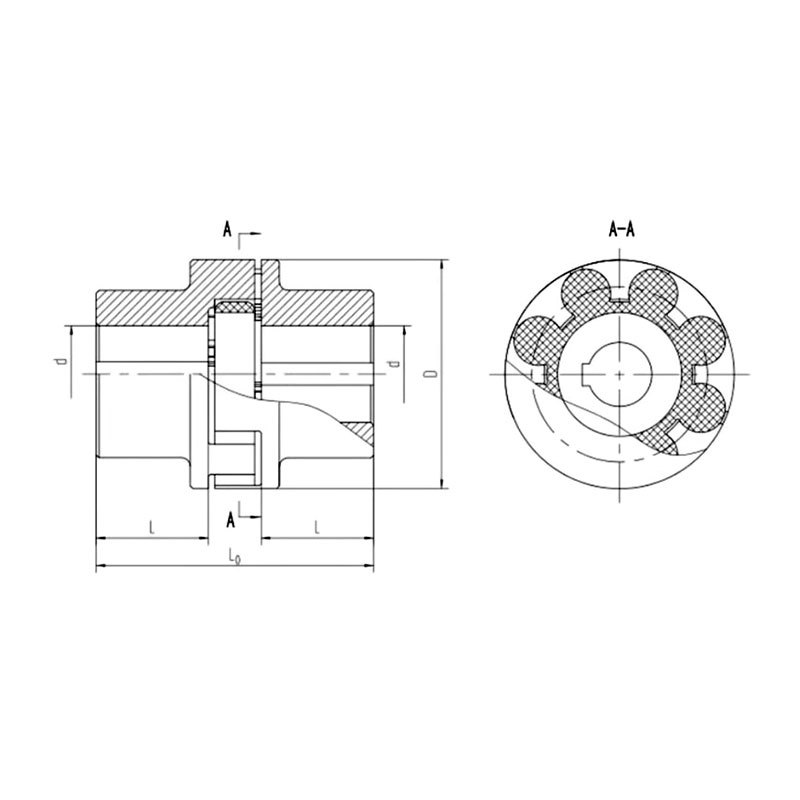

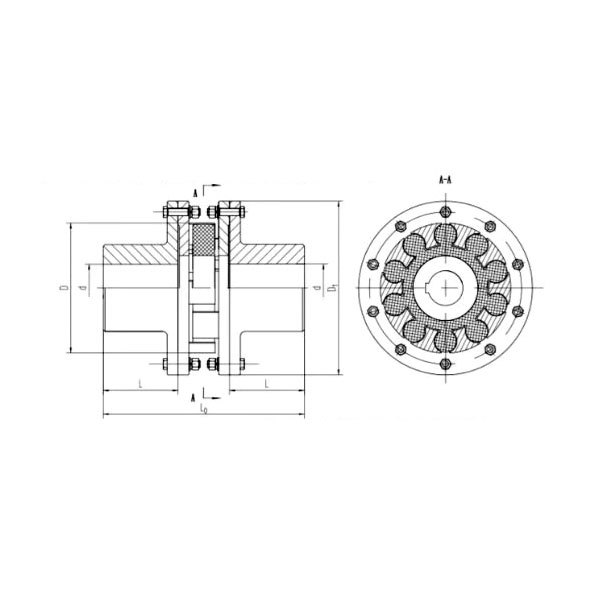

The Lx elastic pin coupling uses several non-metallic elastic pins inserted into the flange holes of the two coupling halves, thereby connecting the two halves via these pins. This coupling boasts a simple structure, is easy to manufacture, and allows for convenient installation, removal, and replacement of the elastic elements without requiring the two coupling halves to be moved.

Application scenarios

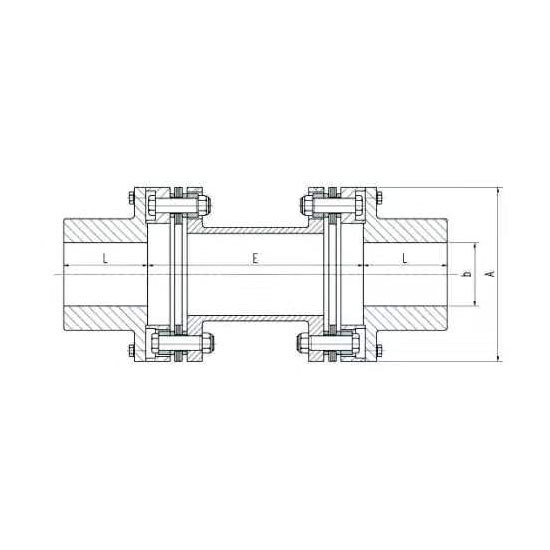

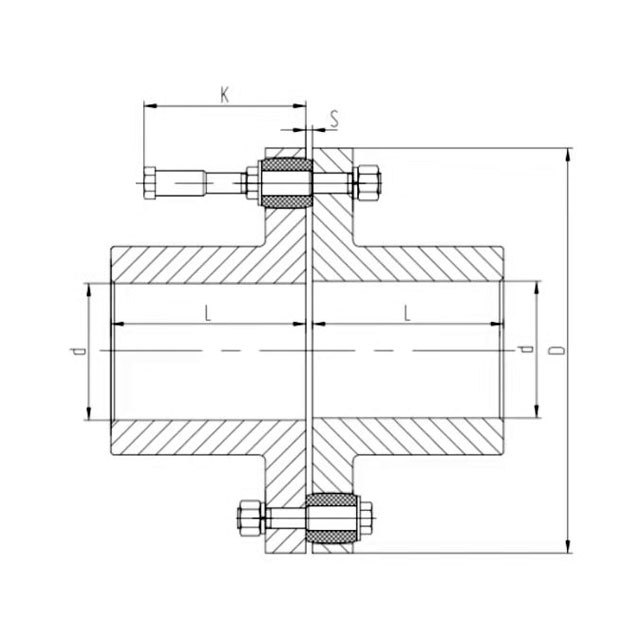

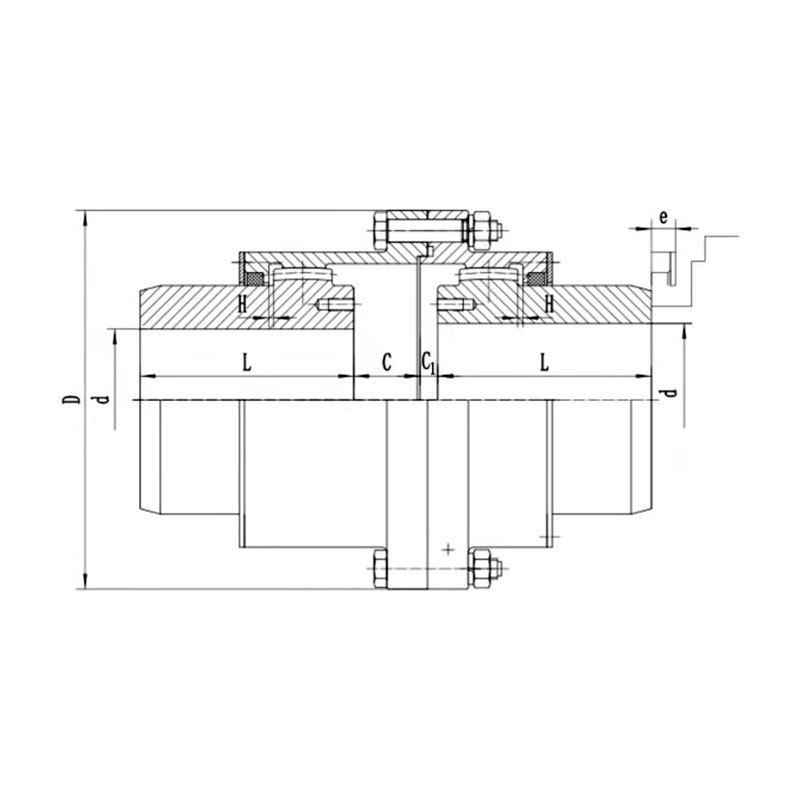

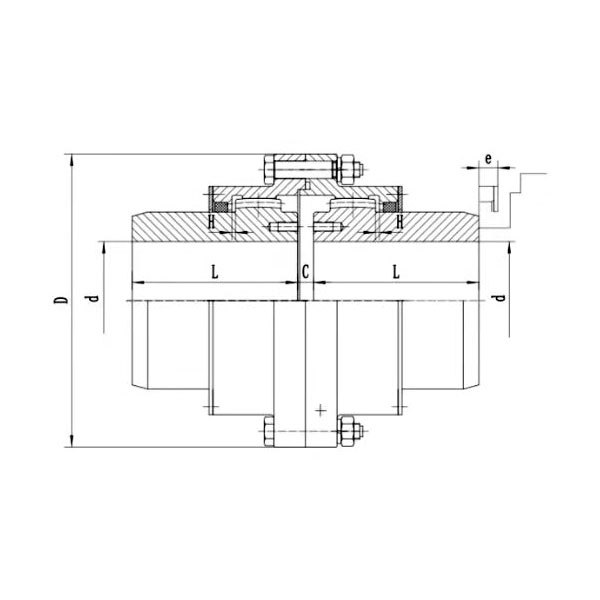

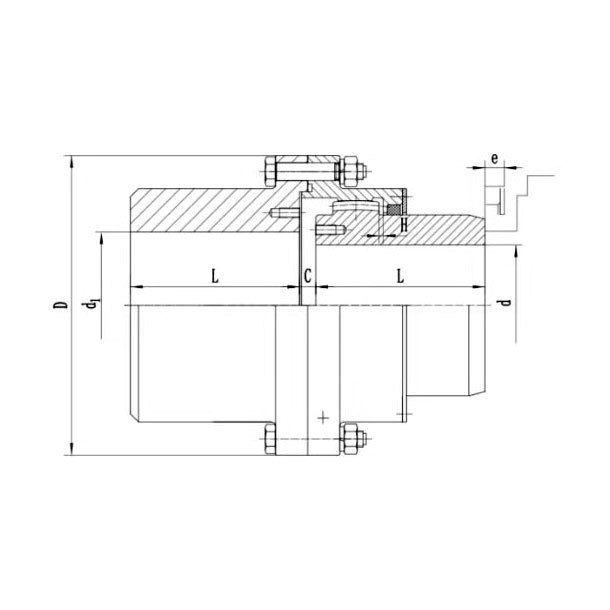

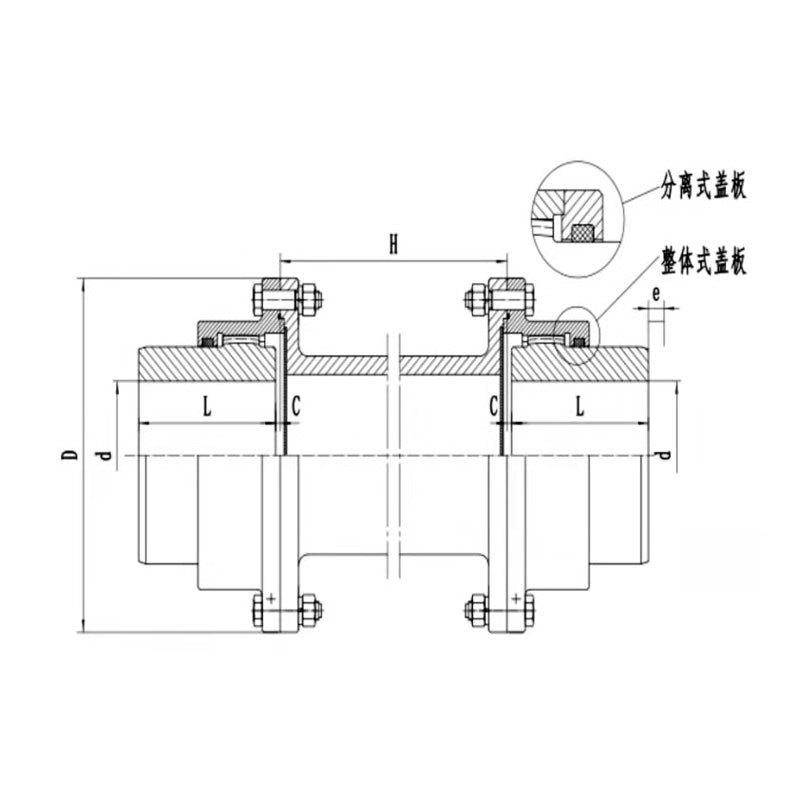

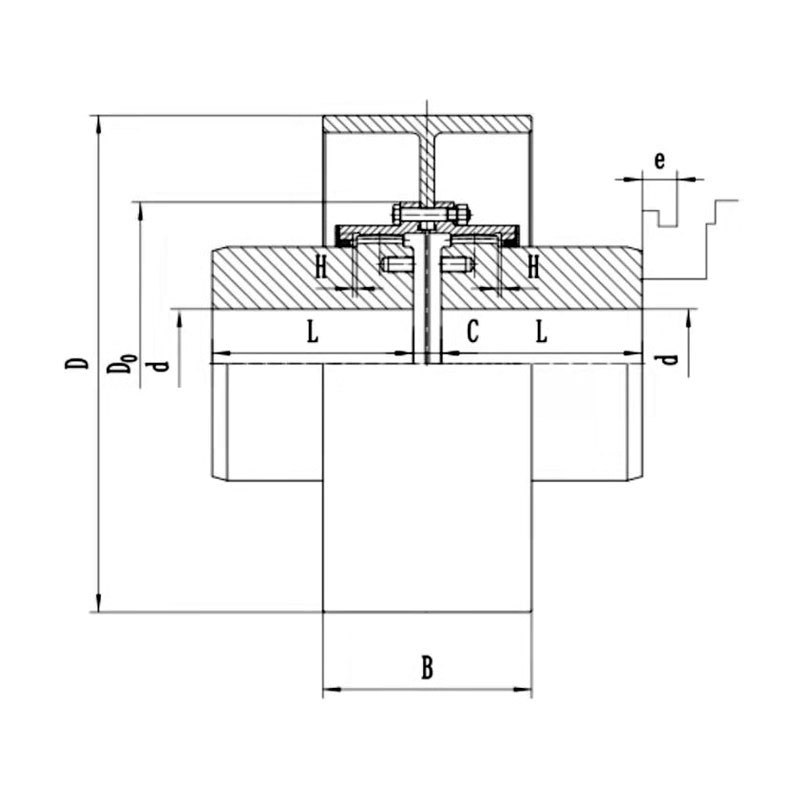

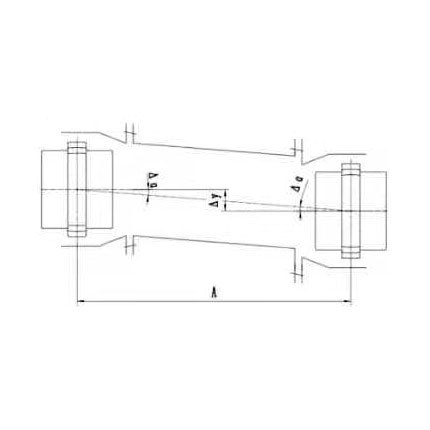

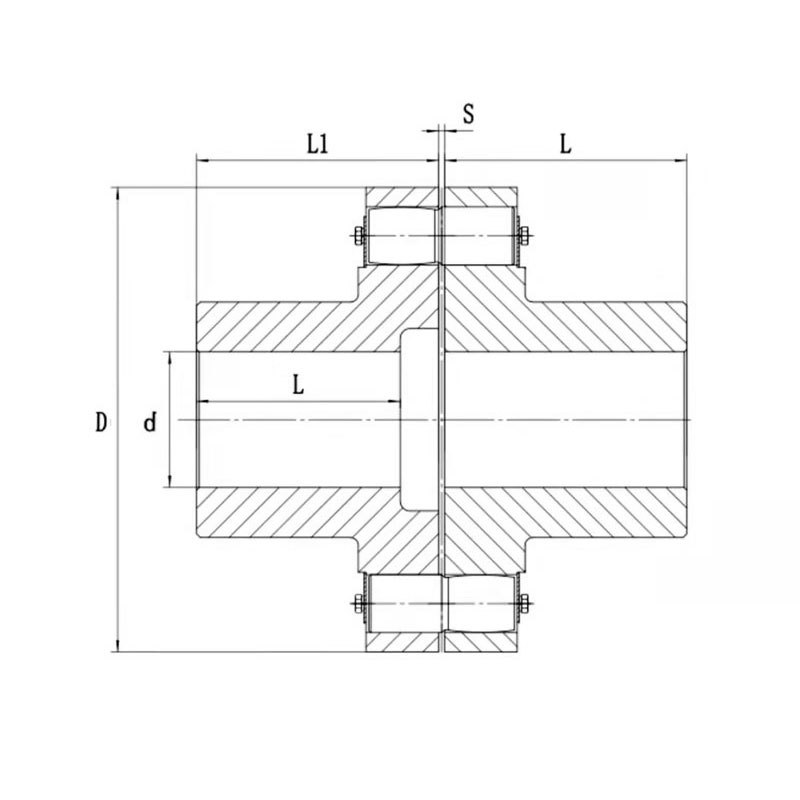

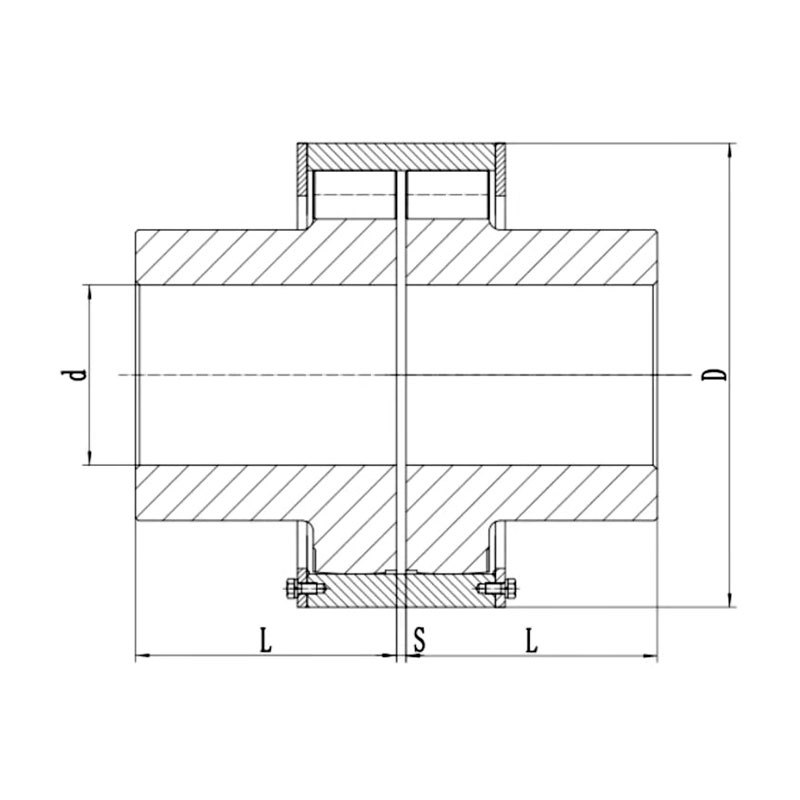

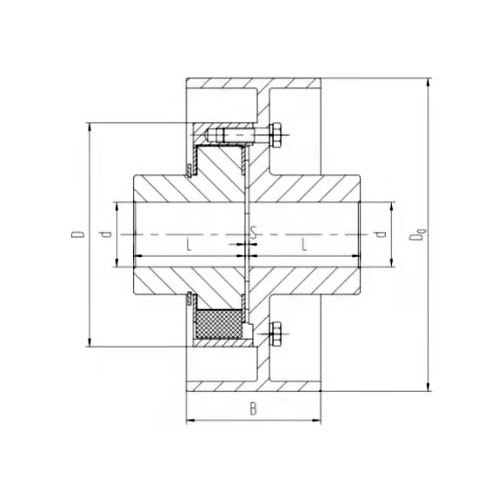

Suitable for transmission shaft systems connecting two coaxial shafts, this component features compensation for relative displacement between the two shafts and general vibration-damping performance. Its operating temperature range is -20°C to +70°C. The structural configuration is shown in Figure 7.1, and the technical parameters and main dimensions are listed in Table 7-1.

Figure 7.1 LX Elastic Pin Coupling

Table 7-1: Technical Parameters and Main Dimensions of the LX Elastic Pin Coupling

| Model | Nominal torque /Nn |

Permissible rotational speed /rmin |

Shaft hole diameter d /mm |

Shaft hole length / mm | D/mm | S/m | Moment of inertia /kg㎡ |

Quality /kg |

Permissible compensation amount | ||||

| Y | J, J1, Z | Axial △x/m |

Radial △y/mm |

Angular △a/° |

|||||||||

| L | L | L1 | |||||||||||

| LX1 | 250 | 8500 | 12, 14 | 32 | 27 | 90 | 2.5 | 0.002 | 2 | ±0.5 | 0.15 | ≤0.5 | |

| 15, 18, 19 | 42 | 30 | 42 | ||||||||||

| 20, 22, 24 | 52 | 38 | 52 | ||||||||||

| LX2 | 560 | 6300 | 20, 22, 24 | 120 | 0.009 | 5 | ±1 | ||||||

| 25, 28 | 62 | 44 | 62 | ||||||||||

| 30, 32, 35 | 82 | 60 | 82 | ||||||||||

| LX3 | 1250 | 4700 | 30, 32, 35, 38 | 160 | 0.026 | 8 | |||||||

| 40, 42, 45, 48 | 112 | 84 | 112 | ||||||||||

| LX4 | 2500 | 3800 | 40, 42, 45, 48, 50, 55, 56 | 195 | 3 | 0.109 | 22 | ±1.5 | |||||

| 60, 63 | 142 | 107 | 142 | ||||||||||

| LX5 | 3150 | 3450 | 50, 55, 56, 60, 63, 65, 70, 71, 75 | 220 | 0.191 | 30 | |||||||

| LX6 | 6300 | 2720 | 60, 63, 65, 70, 71, 75, 80 | 280 | 4 | 0.543 | 53 | ±2 | 0.2 | ||||

| 85 | 172 | 107 | 172 | ||||||||||

| LX7 | 11200 | 2360 | 70, 71, 75 | 142 | 107 | 142 | 320 | 1.314 | 98 | ||||

| 80, 85, 90, 95 | 172 | 132 | 172 | ||||||||||

| 100.110 | 212 | 167 | 212 | ||||||||||

| LX8 | 16000 | 2120 | 80, 85, 90, 95, 100, 110, 120, 125 | 360 | 5 | 2.023 | 119 | ||||||

| LX9 | 22400 | 1850 | 100, 110, 120, 125 | 410 | 4.386 | 197 | |||||||

| 130, 140 | 252 | 202 | 252 | ||||||||||

| LX10 | 35500 | 1600 | 110, 120, 125 | 212 | 167 | 212 | 480 | 6 | 9.760 | 322 | ±2.5 | 0.25 | |

| 130, 140, 150 | 252 | 202 | 252 | ||||||||||

| 160, 170, 180 | 302 | 242 | 302 | ||||||||||

| LX11 | 50000 | 1400 | 130, 140, 150 | 252 | 202 | 252 | 540 | 6 | 20.05 | 520 | |||

| 160, 170, 180 | 302 | 242 | 302 | ||||||||||

| 190, 200, 220 | 352 | 282 | 352 | ||||||||||

| LX12 | 80000 | 1220 | 160, 170, 180 | 302 | 242 | 302 | 630 | 7 | 37.71 | 714 | |||

| 190, 200, 220 | 352 | 282 | 352 | ||||||||||

| 240, 250, 260 | 410 | 330 | - | ||||||||||

| LX13 | 125000 | 1080 | 190, 200, 220 | 352 | 282 | 352 | 710 | 8 | 71.37 | 1057 | ±3 | ||

| 240, 250, 260 | 410 | 330 | - | ||||||||||

| 230, 300 | 470 | 380 | - | ||||||||||

| LX14 | 180000 | 950 | 240, 250, 260 | 410 | 330 | - | 800 | 8 | 170.6 | 1956 | |||

| 230, 300, 320 | 470 | 380 | - | ||||||||||

| 340 | 550 | 450 | - | ||||||||||

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products

T-type and D-type diaphragm couplings

NUP New Elastic Sleeve Pin Coupling

NUPEX Combination Flexible Coupling

GCLD Type Spherical Tooth Coupling

GIICL-type drum-type gear coupling

GIICLZ-type drum-type gear coupling

WGT Type Drum-Type Gear Coupling

NGCL Type Spherical Tooth Coupling

Compensating capacity for relative displacement between the two shafts of a drum-type gear coupling

LM-type梅花-shaped elastic coupling

LMS-type梅花-shaped elastic coupling

Lz-type Elastic Pin-and-Tooth Coupling

LZZ Type Elastic Pin-and-Block Coupling with Brake Wheel

Shenyang Shenke Power Machinery Co,. Ltd.

Address: No. 34 Jia, Kaifa Avenue, Tiexi Economic and Technological Development Zone, Shenyang

Email:sincflex@vip.163.com

Phone:+86 24 25830257

Mobile phone:+86 15940017261

Fax: +86 24 25308993

WeChat contact