F-type diaphragm coupling

Category

Contact Information

Detailed introduction

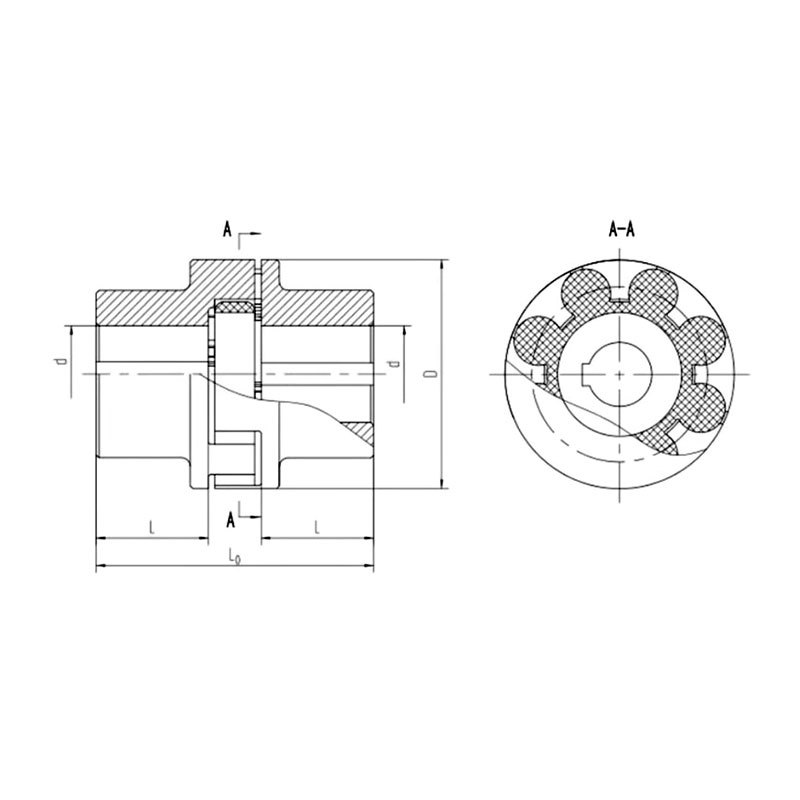

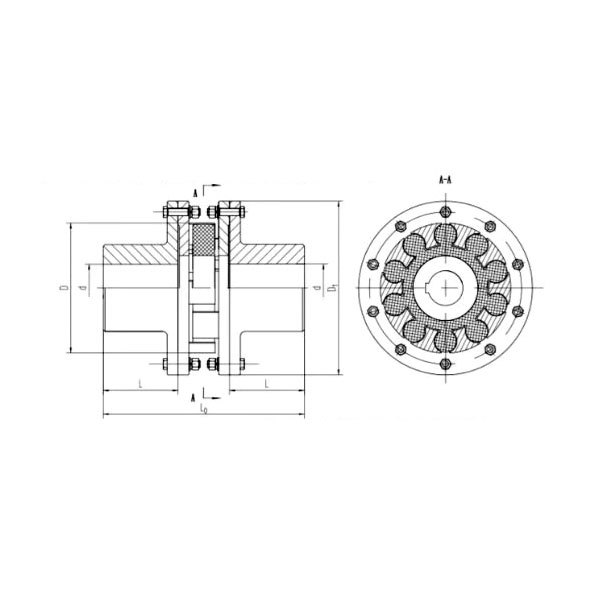

The F-type structure combines the advantages of both the R-type and G-type designs. For the same specification, the F-type offers a greater shaft diameter capacity than the R-type and a smaller outer diameter than the G-type.

F-type couplings are particularly well-suited for large-scale units operating at speeds below 10,000 rpm and are especially ideal for applications requiring quick assembly and disassembly.

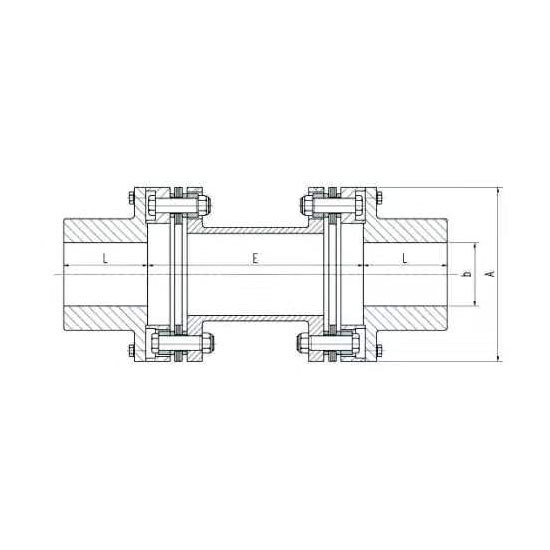

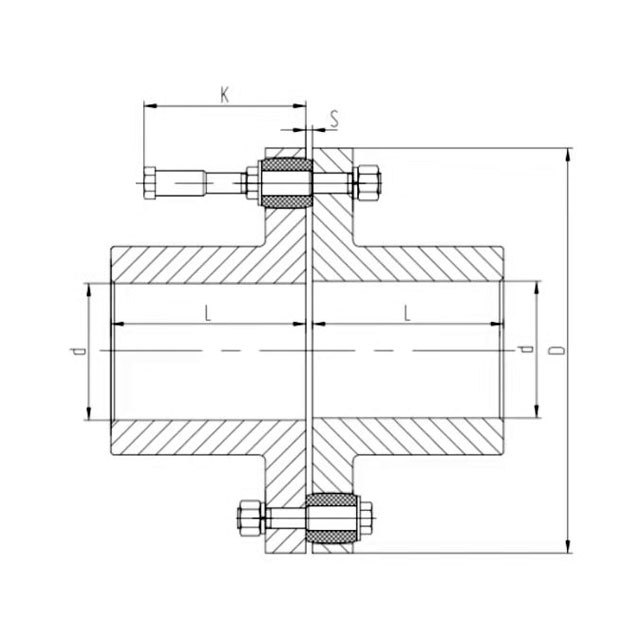

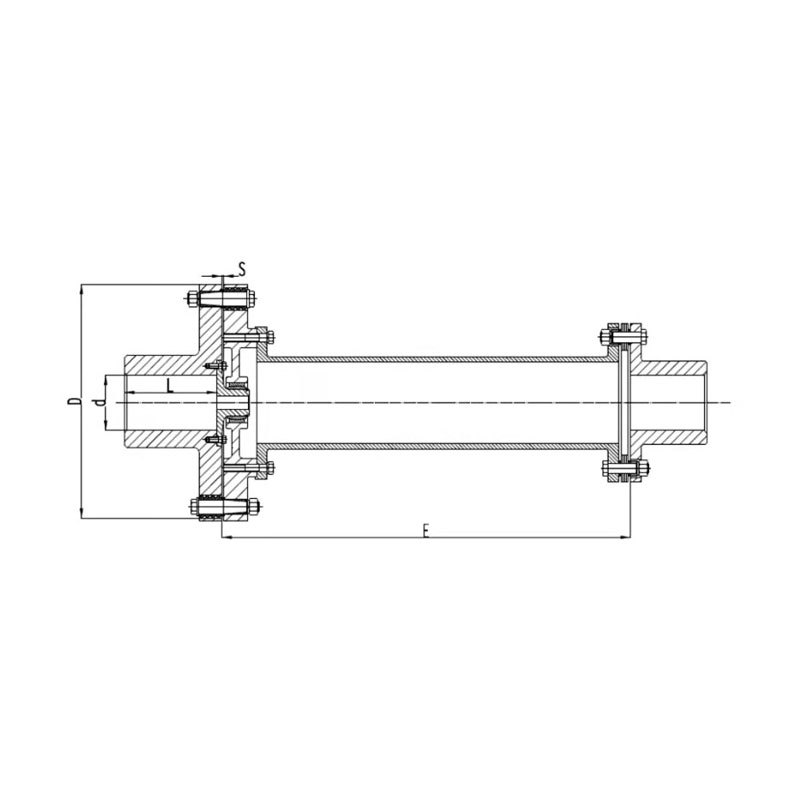

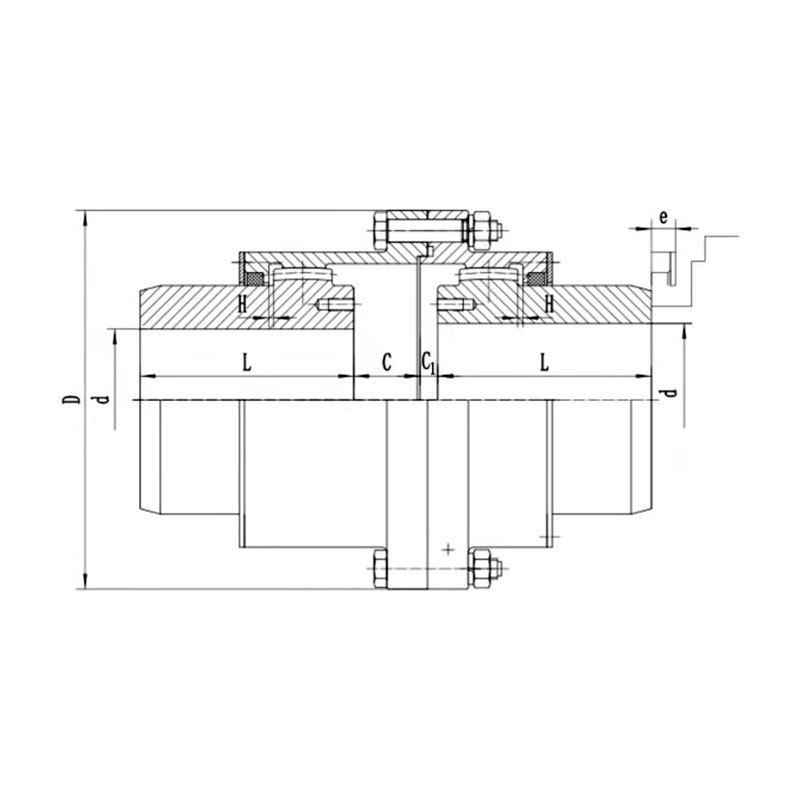

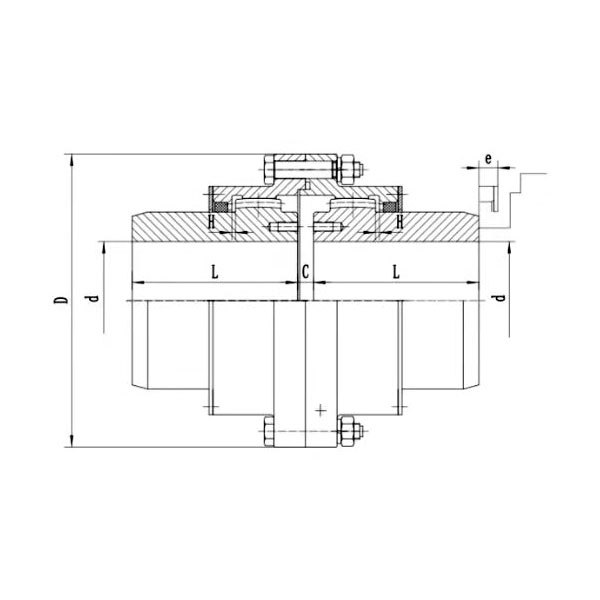

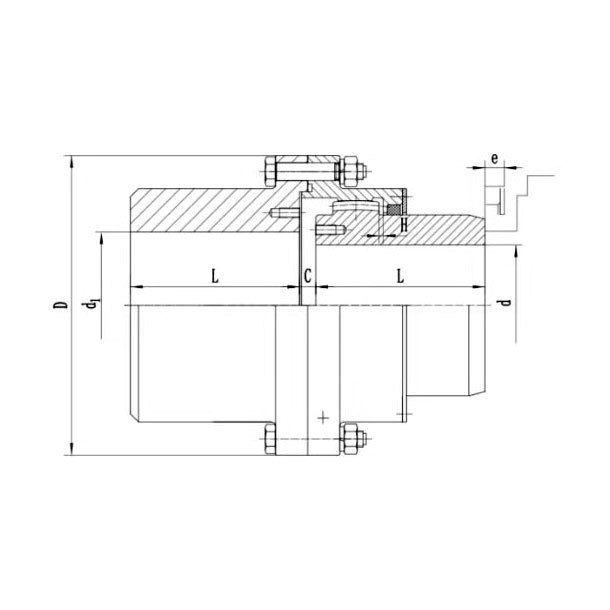

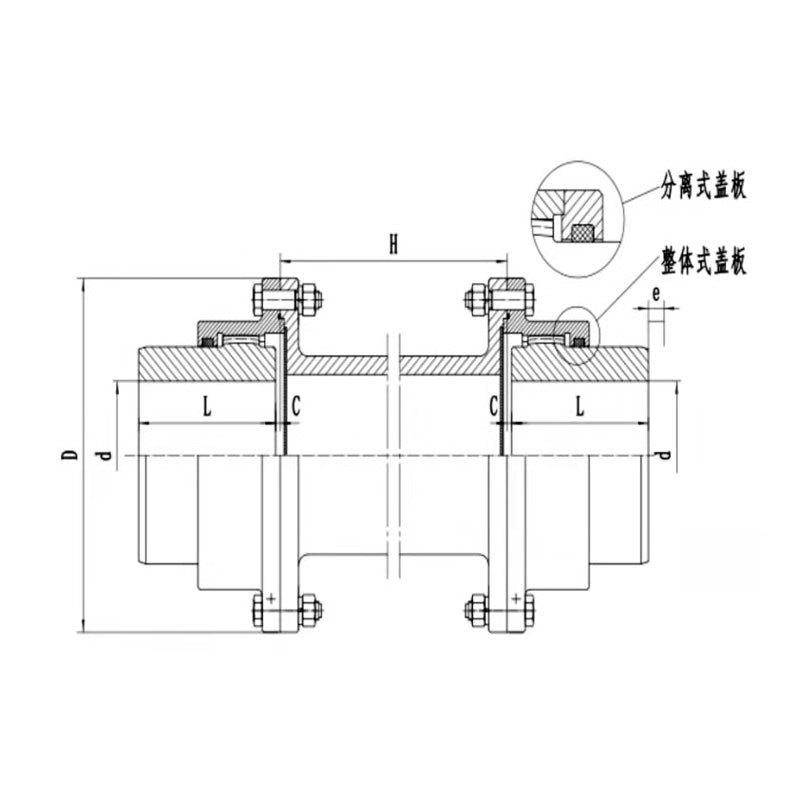

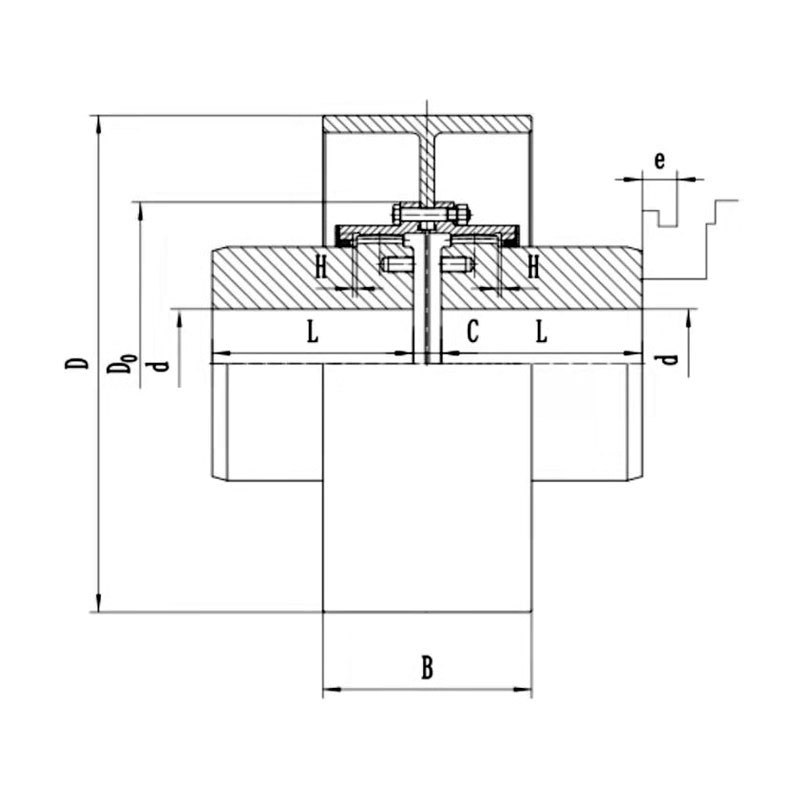

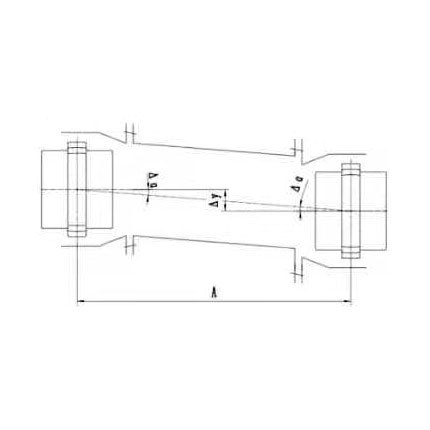

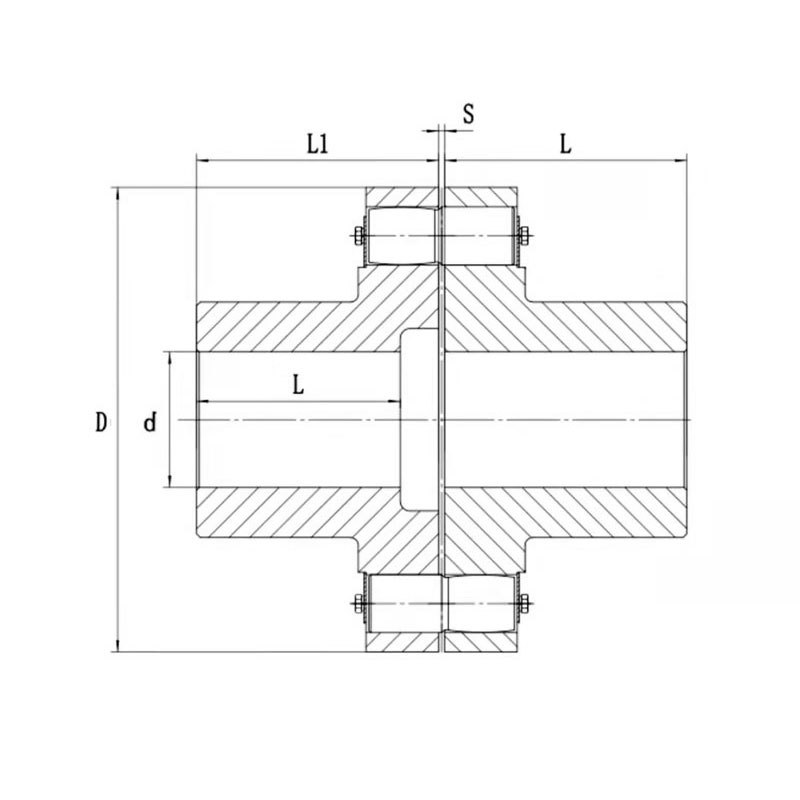

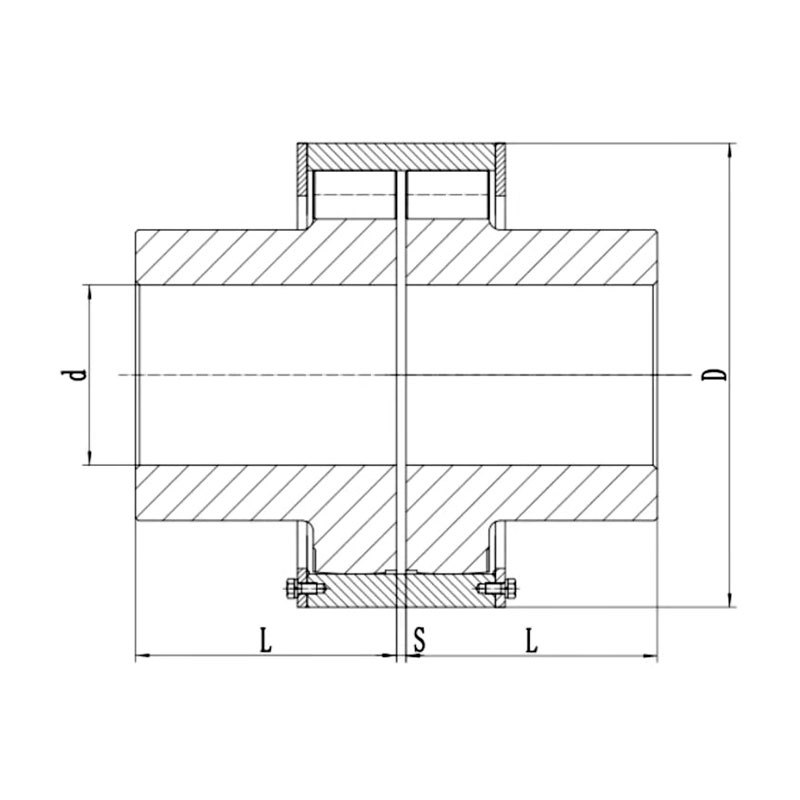

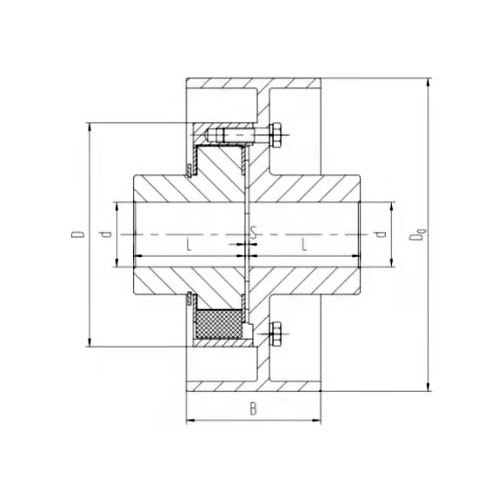

Its structural configuration is shown in Figure 2.3, and the technical parameters and main dimensions are listed in Table 2-2 and Table 2-3.

Figure 2.3F Diaphragm Coupling

Table 2-2F: Main Dimensions of the Diaphragm Coupling

| Model | A | bmax | L | Emin | ||

| 6090 | 95 | 50 | 55 | 80 | ||

| 6120 | 122 | 60 | 65 | 101 | ||

| 6150 | 150 | 80 | 85 | 119 | ||

| 6170 | 170 | 95 | 100 | 136 | ||

| 6190 | 190 | 105 | 115 | 150 | ||

| 6210 | 210 | 120 | 130 | 160 | ||

| 6240 | 8240 | 240 | 130 | 140 | 180 | |

| 6260 | 8260 | 265 | 140 | 150 | 208 | |

| 6280 | 8280 | 280 | 160 | 160 | 208 | |

| 6310 | 8310 | 1310 | 310 | 175 | 185 | 238 |

| 8340 | 1340 | 340 | 190 | 210 | 263 | |

| 8370 | 1370 | 370 | 205 | 220 | 283 | |

| 8400 | 1400 | 400 | 225 | 250 | 291 | |

| 8430 | 1430 | 430 | 245 | 260 | 320 | |

| 8460 | 1460 | 460 | 265 | 280 | 332 | |

| 1490 | 490 | 285 | 295 | 337 | ||

| 1520 | 516 | 295 | 315 | 375 | ||

| 1560 | 560 | 325 | 340 | 375 | ||

| 1600 | 600 | 360 | 380 | 375 | ||

Table 2-3F Type Diaphragm Coupling Technical Parameters

| Model | Permissible Torque Coefficient (kW/rpm) |

Nominal torque (KNm) |

Peak torque (KNm) |

Maximum rotational speed (rpm) |

The entire coupling | Intermediate pipe per meter | Allow axial displacement | Allow angular misalignment (Degree) |

|||||

| Weight (kg) |

Moment of inertia (kg·m²) |

Torsional stiffness TS (MNm/rad) |

Weight (kg) |

Moment of inertia (kg·m²) |

Torsional stiffness TS (MNm/rad) |

Coupling (mm) |

Steering force (N) |

||||||

| 6090 | 0.05 | 0.5 | 0.62 | 35000 | 3.66 | 0.0025 | 0.32 | 3.30 | 0.003 | 0.03 | 1.2 | 480 | 0.375 |

| 6120 | 0.11 | 1.1 | 1.37 | 30000 | 6.90 | 0.01 | 0.67 | 4.13 | 0.004 | 0.04 | 1.8 | 790 | 0.375 |

| 6150 | 0.17 | 1.7 | 2.12 | 26000 | 13.42 | 0.04 | 1.27 | 5.50 | 0.011 | 0.12 | 2.1 | 1000 | 0.375 |

| 6170 | 0.28 | 2.8 | 3.50 | 24000 | 19.88 | 0.08 | 1.73 | 6.14 | 0.015 | 0.16 | 2.9 | 1500 | 0.375 |

| 6190 | 0.48 | 4.8 | 6.00 | 22000 | 30.52 | 0.15 | 3.12 | 9.85 | 0.032 | 0.33 | 3.1 | 1800 | 0.375 |

| 6210 | 0.78 | 7.8 | 9.75 | 20000 | 41.85 | 0.27 | 4.59 | 12.70 | 0.052 | 0.55 | 3.5 | 1900 | 0.375 |

| 6240 | 1.20 | 12 | 15.00 | 17500 | 55.00 | 0.45 | 6.28 | 15.92 | 0.090 | 0.92 | 4.2 | 2600 | 0.375 |

| 6260 | 1.50 | 15 | 18.75 | 16500 | 70.00 | 0.76 | 8.65 | 18.36 | 0.180 | 1.90 | 4.6 | 2900 | 0.375 |

| 6280 | 1.75 | 17.5 | 21.87 | 16000 | 88.83 | 0.99 | 10.75 | 22.00 | 0.290 | 2.92 | 5.0 | 3300 | 0.375 |

| 6310 | 2.36 | 23.6 | 29.50 | 13500 | 122.00 | 1.70 | 13.50 | 29.94 | 0.300 | 3.05 | 5.5 | 4000 | 0.375 |

| 8240 | 1.5 | 15.0 | 18.75 | 17500 | 55.00 | 0.45 | 6.28 | 15.72 | 0.090 | 0.92 | 2.5 | 3000 | 0.250 |

| 8260 | 1.75 | 17.5 | 21.87 | 16500 | 70.00 | 0.76 | 8.65 | 18.36 | 0.180 | 1.90 | 4.6 | 2900 | 0.375 |

| 8280 | 2.68 | 26.8 | 33.50 | 16000 | 88.83 | 0.99 | 10.75 | 22.00 | 0.290 | 2.92 | 3.1 | 4000 | 0.250 |

| 8310 | 2.96 | 29.6 | 37.00 | 13500 | 122.00 | 1.70 | 13.50 | 29.94 | 0.300 | 3.05 | 3.8 | 4900 | 0.250 |

| 8340 | 3.75 | 37.5 | 46.87 | 12000 | 165.00 | 2.73 | 16.35 | 38.28 | 0.460 | 4.63 | 4.2 | 7000 | 0.250 |

| 8370 | 4.70 | 47.0 | 58.75 | 11000 | 207.00 | 4.05 | 22.00 | 47.50 | 0.690 | 6.95 | 4.6 | 8900 | 0.250 |

| 8400 | 6.30 | 63.0 | 78.75 | 10000 | 238.00 | 7.49 | 25.36 | 55.60 | 0.950 | 9.60 | 5.1 | 10000 | 0.250 |

| 8430 | 8.00 | 80.0 | 100.00 | 9500 | 334.00 | 8.87 | 38.65 | 63.80 | 1.350 | 13.90 | 5.9 | 12000 | 0.250 |

| 8460 | 8.50 | 85.0 | 106.25 | 9000 | 410.00 | 12.68 | 49.65 | 75.62 | 1.750 | 18.00 | 6.3 | 14000 | 0.250 |

| 8490 | 10.50 | 105.0 | 131.25 | 8500 | 487.00 | 16.90 | 60.50 | 80.60 | 2.100 | 22.00 | 6.8 | 15000 | 0.250 |

| 1310 | 3.92 | 39.2 | 49.85 | 13500 | 122.00 | 1.70 | 13.50 | 29.94 | 0.300 | 3.05 | 2.4 | 8000 | 0.165 |

| 1340 | 4.87 | 48.7 | 61.90 | 12000 | 165.00 | 2.73 | 16.35 | 38.28 | 0.460 | 4.63 | 2.8 | 15000 | 0.165 |

| 1370 | 6.25 | 62.5 | 79.35 | 11000 | 207.00 | 4.05 | 22.00 | 47.50 | 0.690 | 6.95 | 3.2 | 16500 | 0.165 |

| 1400 | 8.40 | 84.0 | 106.65 | 10000 | 238.00 | 7.49 | 25.36 | 55.60 | 0.950 | 9.60 | 3.6 | 19000 | 0.165 |

| 1430 | 10.65 | 106.5 | 135.50 | 9500 | 334.00 | 8.87 | 38.65 | 63.80 | 1.350 | 13.90 | 4.0 | 21000 | 0.165 |

| 1460 | 11.3 | 113.0 | 143.50 | 9000 | 410.00 | 12.68 | 49.65 | 75.60 | 1.750 | 18.00 | 4.3 | 22000 | 0.165 |

| 1490 | 14.00 | 140.0 | 177.80 | 8500 | 487.00 | 16.90 | 60.50 | 80.60 | 2.100 | 22.00 | 4.7 | 23000 | 0.165 |

| 1520 | 16.50 | 165.0 | 206.25 | 7700 | 583.00 | 22.36 | 70.00 | 86.00 | 2.550 | 26.00 | 5.0 | 27000 | 0.165 |

| 1560 | 18.30 | 183.0 | 228.75 | 7500 | 731.00 | 33.44 | 106.57 | 93.50 | 3.300 | 34.50 | 5.7 | 30000 | 0.165 |

| 1600 | 26.00 | 260.0 | 325.00 | 7000 | 908.00 | 47.89 | 140.48 | 142.00 | 5.200 | 54.71 | 6.2 | 35000 | 0.165 |

Note:

1. The parameters in the technical data sheet are all based on the dimensions provided in the size chart.

2. Users often request changes to the shaft-to-shaft distance E; the parameters of the deformed coupling can be easily calculated based on the data provided in the table.

T = Torsional stiffness

E = New spindle center distance

3. For other changes, please contact Schenker’s Engineering Department.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products