T-type and D-type diaphragm couplings

Category

Contact Information

Detailed introduction

Product Features

The diaphragm coupling compensates for the relative displacement between the two connected shafts through the elastic deformation of its diaphragm, making it a high-performance, metal-based flexible coupling with strong mechanical properties.

1. It has strong capability to compensate for misalignment between the two shafts; compared with gear couplings, it can accommodate twice as much angular displacement. When there is radial displacement, the reaction force is small, and its flexibility is high, allowing for certain axial, radial, and angular displacements.

2. It has a noticeable shock-absorbing effect, produces no noise, and is wear-free.

3. Able to operate safely under high-temperature conditions (-80~+300) and in harsh environments, and capable of reliable operation even under impact and vibration conditions.

4. High transmission efficiency, reaching up to 99.86%. Particularly suitable for medium- and high-speed, high-power transmissions.

5. Simple structure, lightweight, compact size, and easy to assemble and disassemble. Assembly and disassembly can be carried out without moving the machine (referring to models with an intermediate shaft), and no lubrication is required.

6. It can accurately transmit rotational speed with no slip during operation, making it suitable for the transmission of precision machinery.

Application scenarios

Widely used in shaft transmission systems for various mechanical devices, such as pumps (especially high-power and chemical pumps), fans, compressors, hydraulic machinery, petroleum equipment, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aerospace (helicopters), high-speed propulsion systems for ships, steam turbines, reciprocating power machinery transmission systems, tracked vehicles, and high-speed, high-power mechanical transmission systems for generator sets—after dynamic balancing, their application in high-speed shaft transmission systems has become quite common.

T-type and D-type diaphragm couplings

It features a simple structure for easy disassembly and assembly, small size, light weight, high torque transmission capability, excellent ability to accommodate misalignment in the equipment set, effective noise reduction and vibration damping, and is safe, reliable, maintenance-free, and boasts a long service life. It is suitable for various rotating equipment such as pumps, blowers, mills, rolling mills, and more.

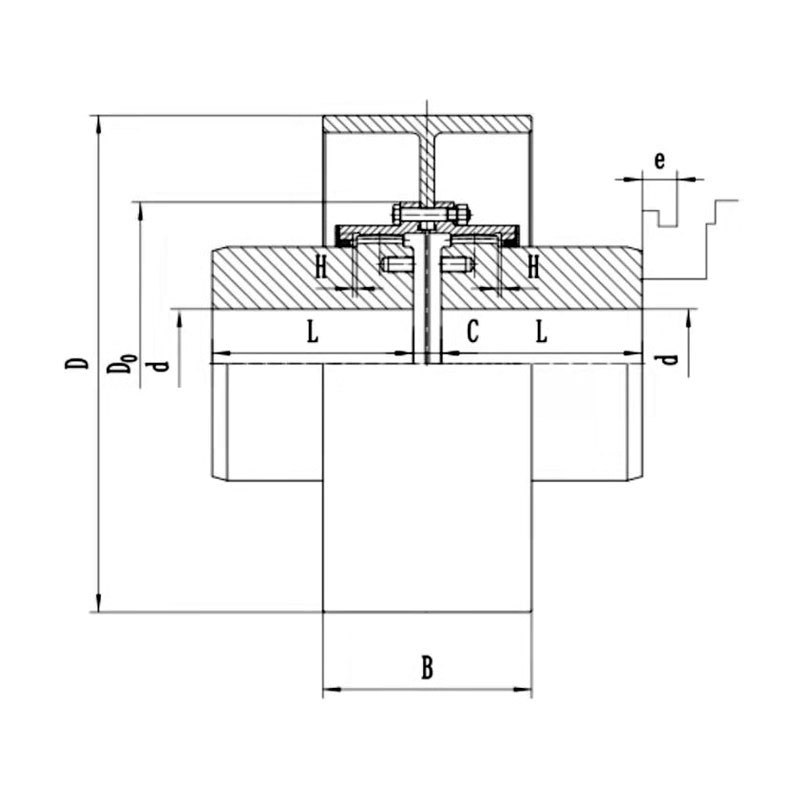

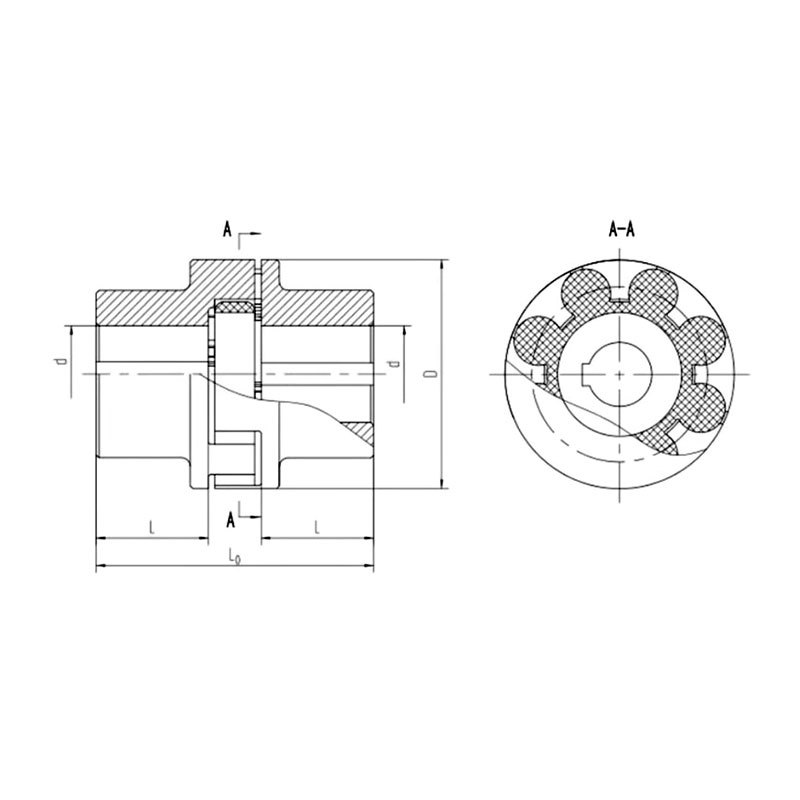

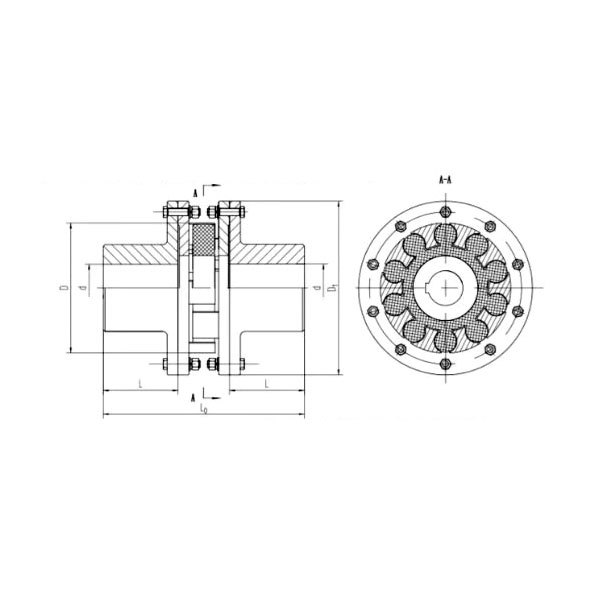

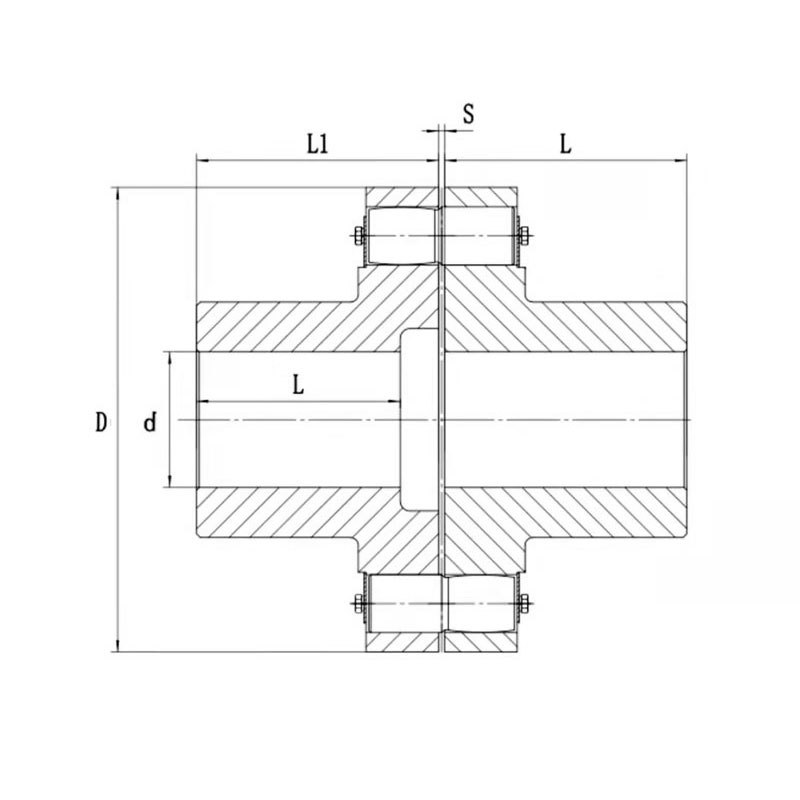

The structural configurations are shown in Figures 2.1 and 2.2, and the technical parameters and main dimensions are listed in Table 2-1.

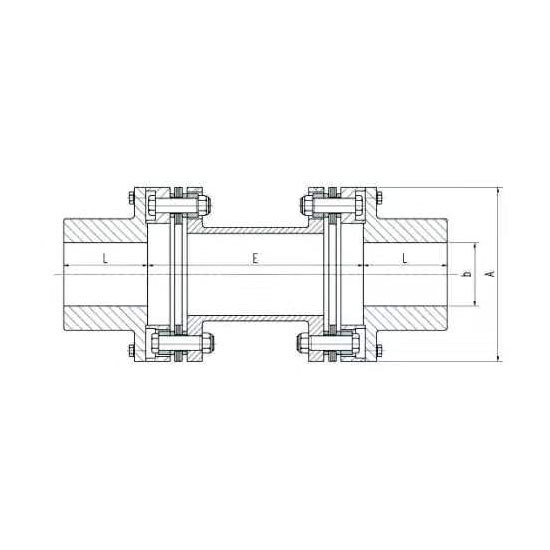

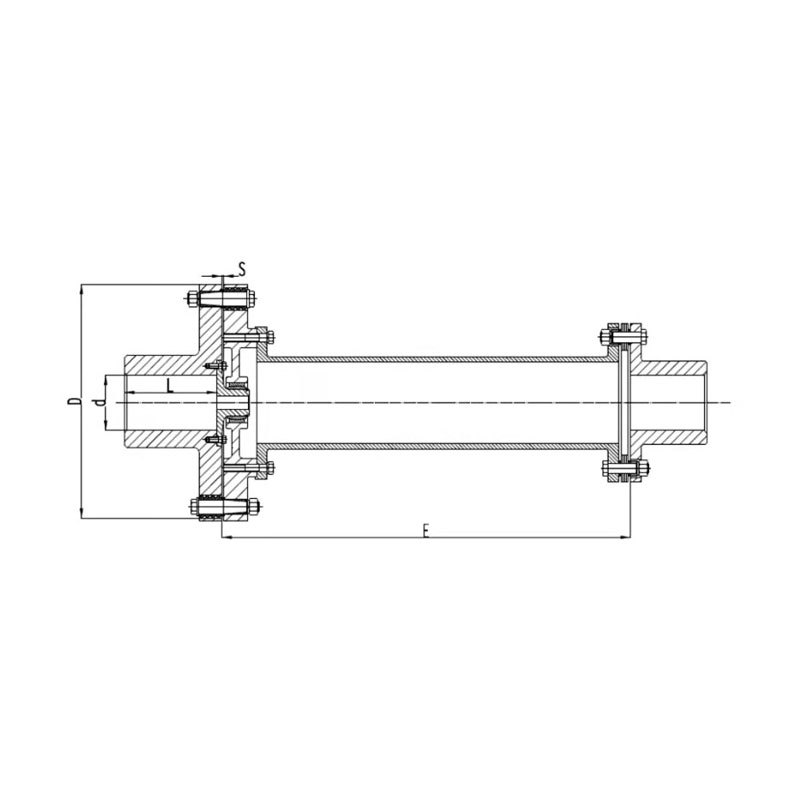

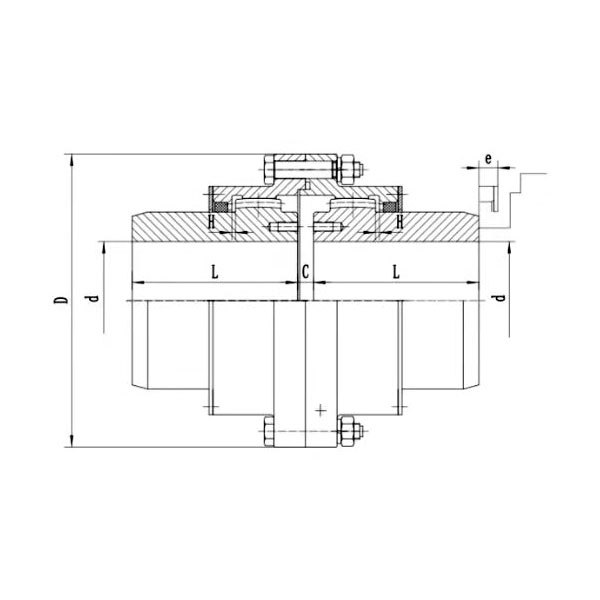

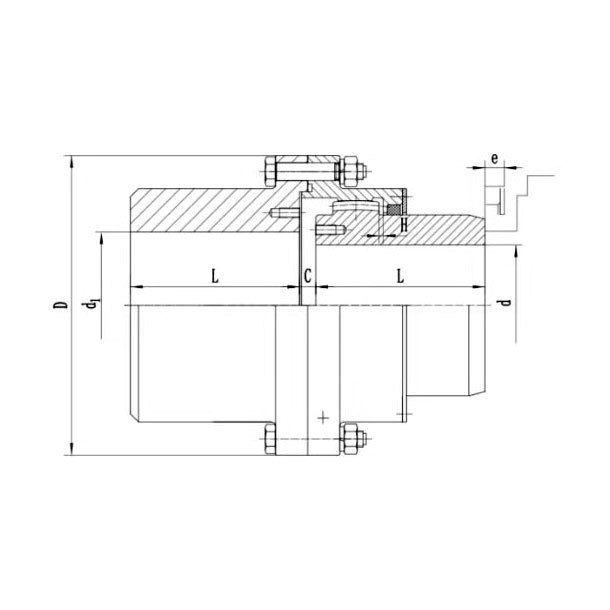

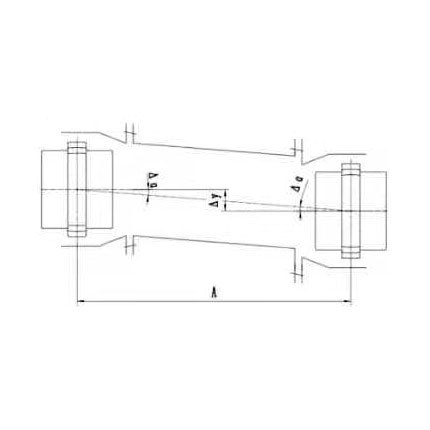

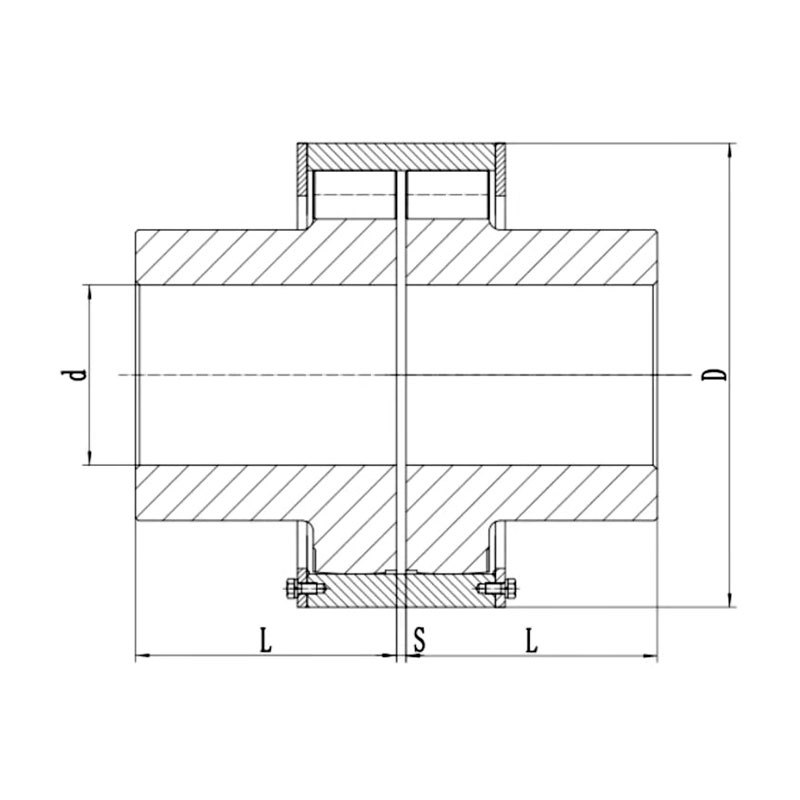

Figure 2.1 T-type diaphragm coupling

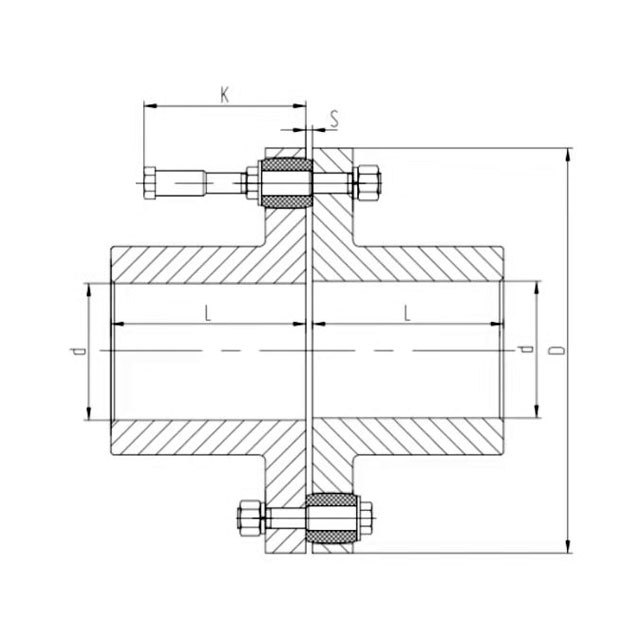

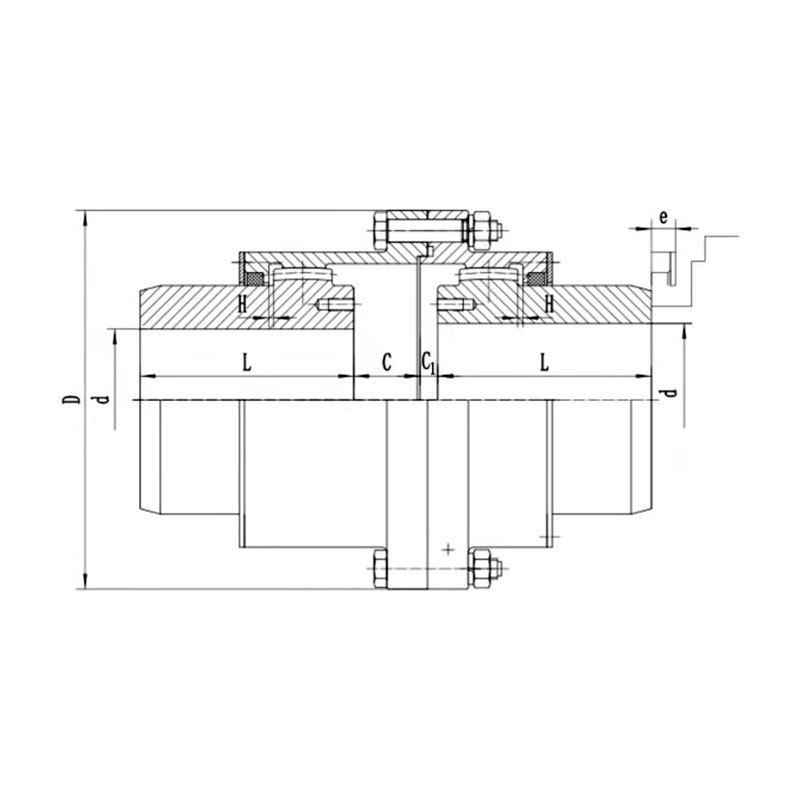

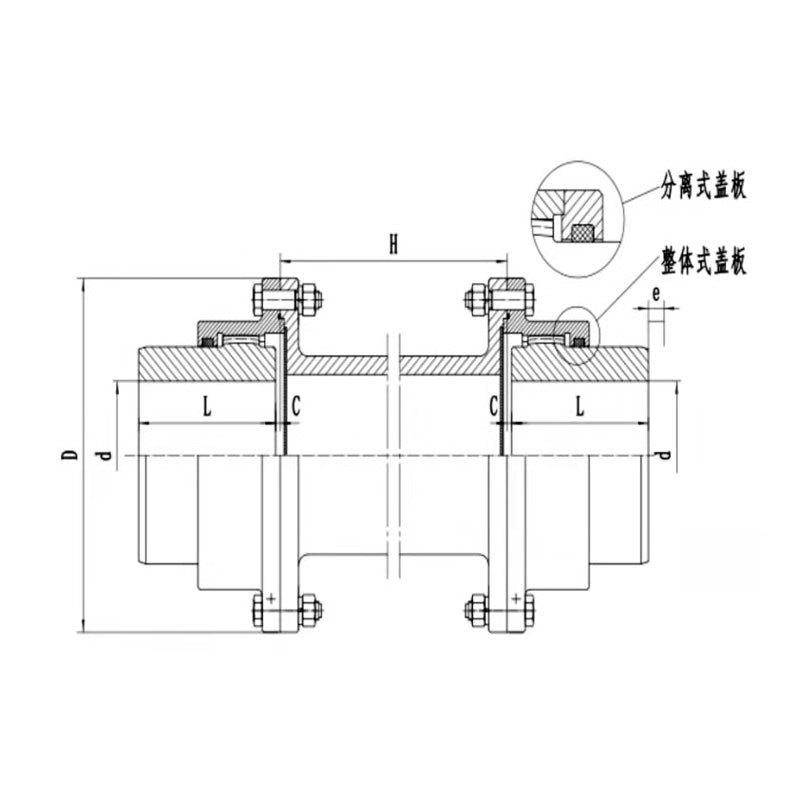

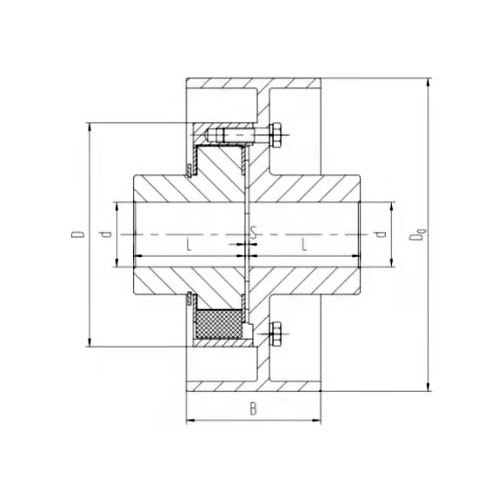

Figure 2.2 Type D Diaphragm Coupling

Table 2-1: Technical Parameters and Main Dimensions of T-Type and D-Type Diaphragm Couplings

| Model | Permissible Torque Coefficient TN (kW/rpm) |

Nominal torque Mr. (KNm) |

Peak torque Tmax (KNm) |

Permissible Rotational Speed n (rpm) |

Outer diameter A (mm) |

Shaft hole b Max (mm) |

Shaft extension L Max (mm) |

Axle spacing Emin (mm) |

Weight (kg) |

Moment of inertia kg·m² |

Misalignment Compensation Amount | ||

| T-shaped | Type D | Axial (mm) |

Angular direction (Degree) |

||||||||||

| 6090 | 0.05 | 0.5 | 0.62 | 35000 | 95 | 38 | 50 | 85 | 2 | 2.50 | 0.003 | 2 | 0.500 |

| 6120 | 0.11 | 1.1 | 1.37 | 30000 | 122 | 42 | 60 | 110 | 3 | 5.50 | 0.009 | 3 | 0.500 |

| 6150 | 0.17 | 1.7 | 2.12 | 26000 | 150 | 65 | 70 | 110 | 3 | 10.60 | 0.03 | 3 | 0.375 |

| 6170 | 0.28 | 2.8 | 3.50 | 24000 | 170 | 80 | 80 | 125 | 3 | 14.90 | 0.05 | 3 | 0.375 |

| 6190 | 0.48 | 4.8 | 6.00 | 22000 | 190 | 90 | 100 | 140 | 3 | 21.60 | 0.09 | 3 | 0.375 |

| 6210 | 0.78 | 7.8 | 9.75 | 20000 | 210 | 100 | 110 | 145 | 3 | 29.30 | 0.16 | 3 | 0.375 |

| 6240 | 1.2 | 12 | 15.00 | 17500 | 240 | 120 | 135 | 160 | 3 | 47.00 | 0.33 | 3 | 0.375 |

| 6260 | 1.5 | 15 | 18.75 | 17000 | 265 | 130 | 150 | 170 | 3 | 55.00 | 0.54 | 3 | 0.375 |

| 6280 | 1.75 | 17.5 | 21.87 | 16000 | 280 | 140 | 160 | 175 | 3 | 72.20 | 0.67 | 3 | 0.375 |

| 8310 | 2.96 | 29.6 | 37.00 | 13500 | 310 | 155 | 180 | 200 | 4 | 106.20 | 1.20 | 4 | 0.250 |

| 8340 | 3.75 | 37.5 | 46.87 | 12000 | 340 | 170 | 200 | 230 | 4 | 138.20 | 1.92 | 4 | 0.250 |

| 8370 | 4.70 | 47.0 | 58.75 | 11000 | 370 | 185 | 220 | 240 | 4 | 176.90 | 3.63 | 4 | 0.250 |

| 8400 | 6.30 | 63.0 | 78.75 | 10000 | 400 | 200 | 235 | 250 | 4 | 226.80 | 4.32 | 4 | 0.250 |

| 8430 | 8.00 | 80.0 | 100.00 | 9500 | 430 | 210 | 245 | 285 | 4 | 282.60 | 6.4 | 4 | 0.250 |

| 8460 | 8.50 | 85.0 | 106.25 | 8900 | 460 | 230 | 270 | 295 | 5 | 345.00 | 8.9 | 5 | 0.250 |

| 8490 | 10.50 | 105.0 | 131.25 | 8200 | 490 | 245 | 290 | 305 | 5 | 404.00 | 12 | 5 | 0.250 |

| 1520 | 16.50 | 165.0 | 206.25 | 7500 | 516 | 255 | 325 | 340 | 5 | 508.60 | 17 | 5 | 0.165 |

| 1560 | 18.30 | 183.0 | 228.75 | 7100 | 560 | 280 | 350 | 340 | 6 | 645.00 | 17 | 6 | 0.165 |

| 1600 | 26.00 | 260.0 | 325.00 | 6500 | 600 | 310 | 380 | 370 | 6 | 823.60 | 27 | 6 | 0.165 |

| 1650 | 39.00 | 390.0 | 487.50 | 5800 | 650 | 330 | 410 | 400 | 6 | 1054.8 | 54 | 6 | 0.165 |

| 1720 | 52.50 | 525.0 | 656.25 | 5400 | 720 | 360 | 445 | 420 | 6 | 1258.0 | 81 | 6 | 0.165 |

| 1800 | 82.50 | 825.0 | 1031.25 | 4200 | 800 | 410 | 520 | 440 | 7 | 2007.0 | 159 | 7 | 0.165 |

| 1890 | 112.50 | 1125.0 | 1406.25 | 3500 | 890 | 445 | 600 | 440 | 7 | 2866.0 | 289 | 7 | 0.165 |

| 1990 | 160.0 | 1600.0 | 2000 | 3000 | 990 | 500 | 720 | 460 | 7 | 4580.0 | 557 | 7 | 0.165 |

Note: The data in the table can be adjusted according to user unit requirements.

The data for Type D is about half that of Type T.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products