WGT Type Drum-Type Gear Coupling

Category

Contact Information

Detailed introduction

Product Features

The drum-type gear coupling is a type of rigid-flexible coupling that can compensate for misalignment along the radial, axial, and angular directions. Compared to straight-tooth couplings, it offers advantages such as a compact structure, a small turning radius, high load-carrying capacity, high transmission efficiency, low noise, and a long maintenance interval.

Application scenarios

Suitable for shaft transmission systems in industries such as metallurgy, mining, lifting and transportation, as well as for various types of machinery including petroleum, chemical, and general-purpose machinery.

WGT Type Drum-Type Gear Coupling

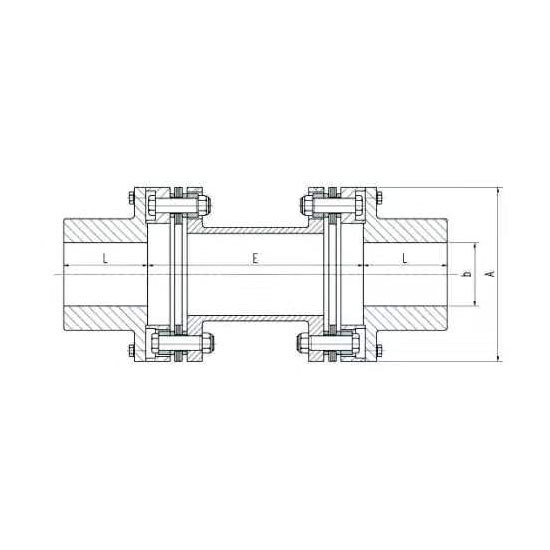

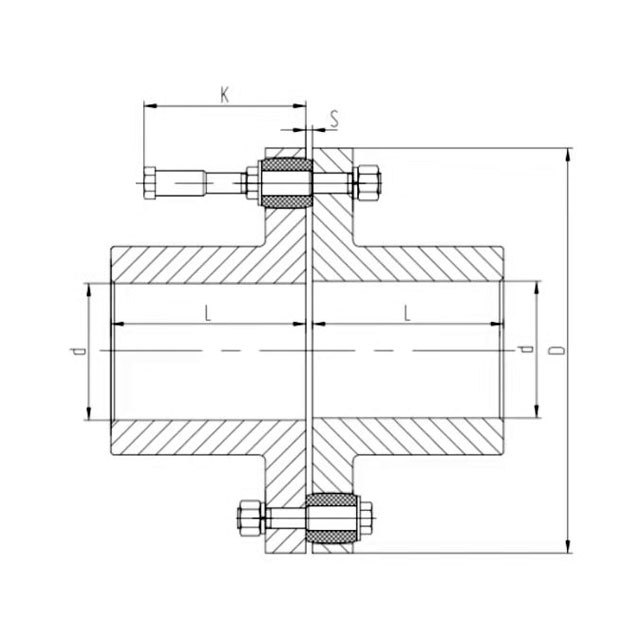

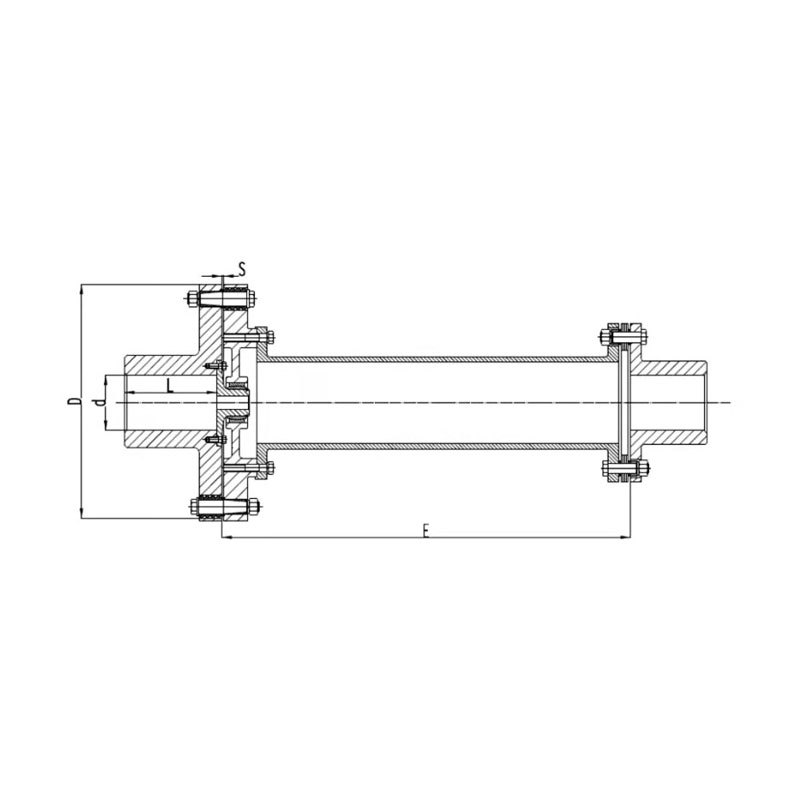

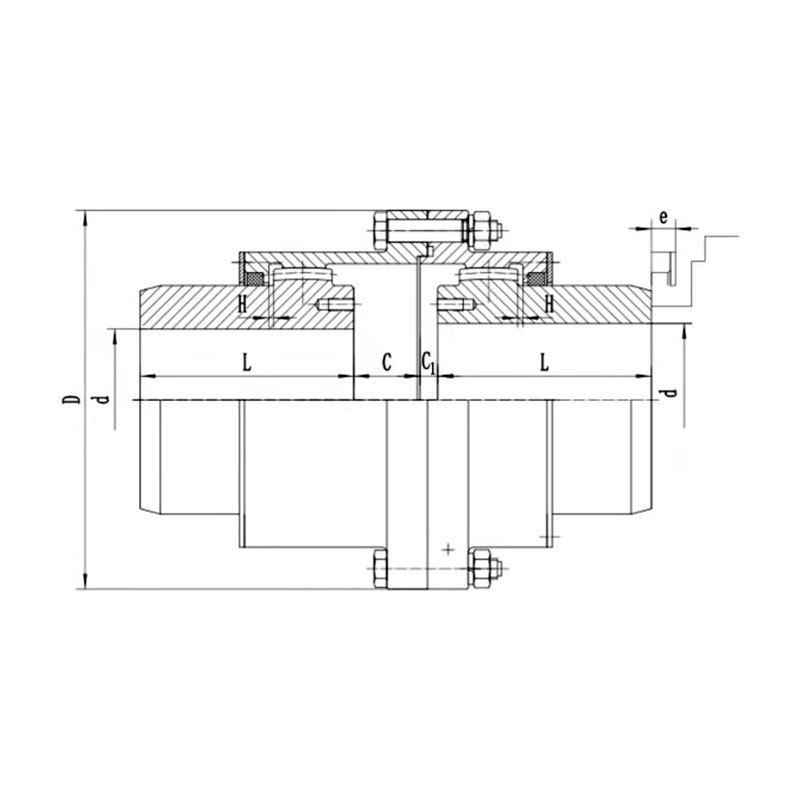

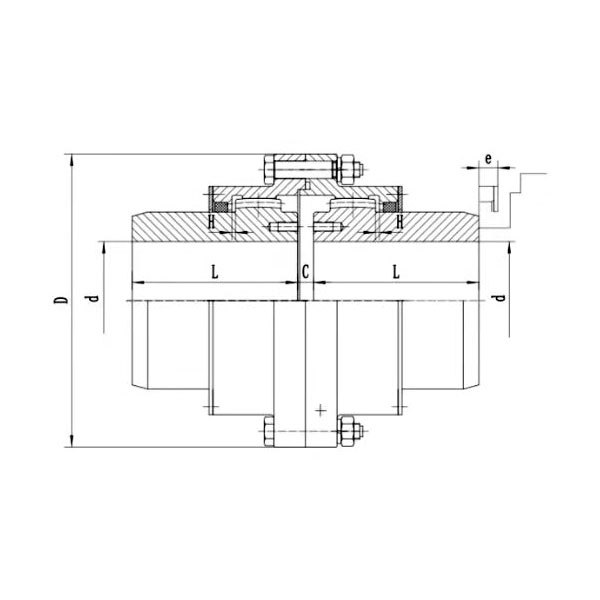

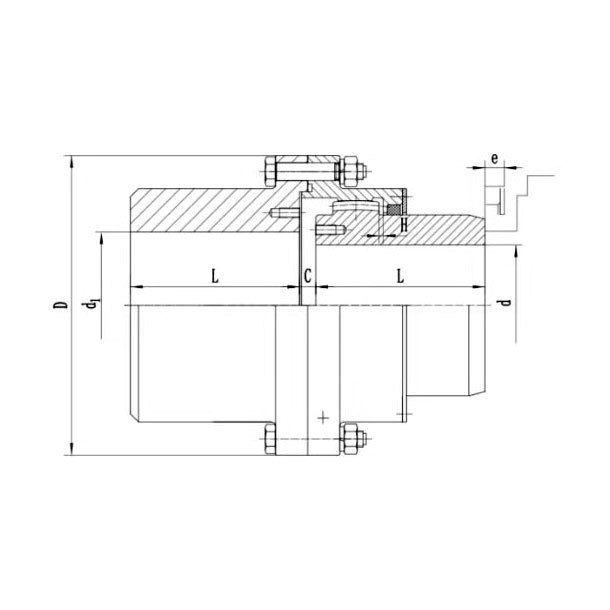

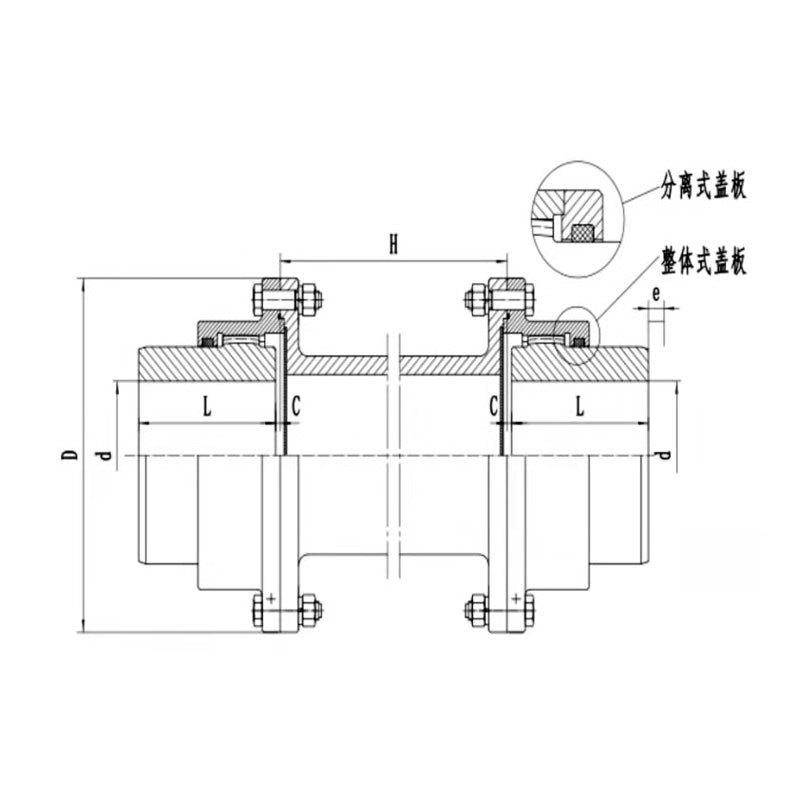

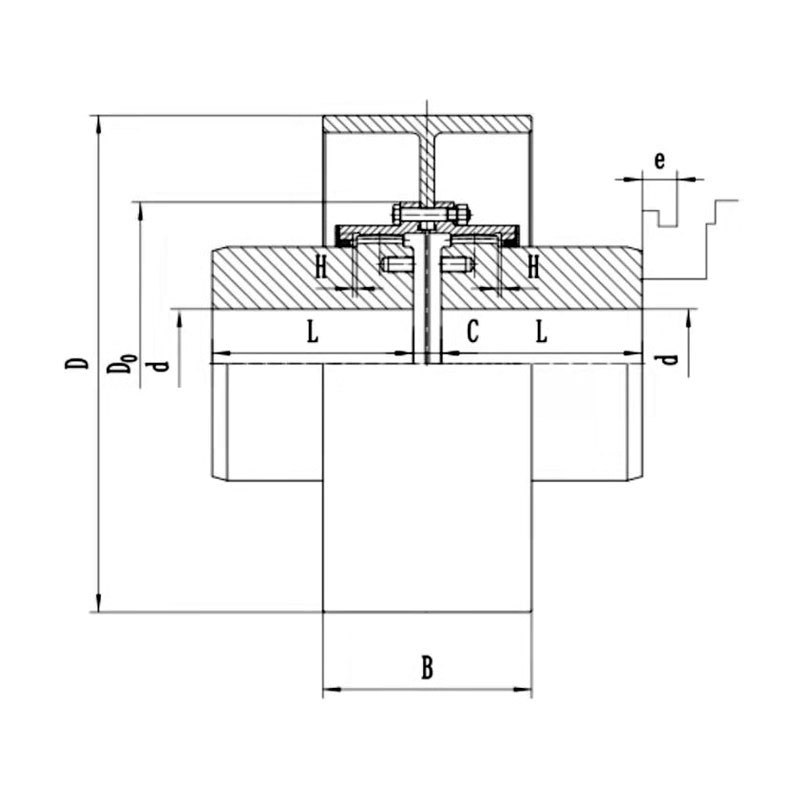

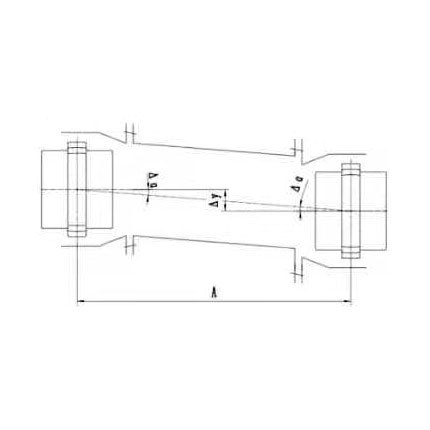

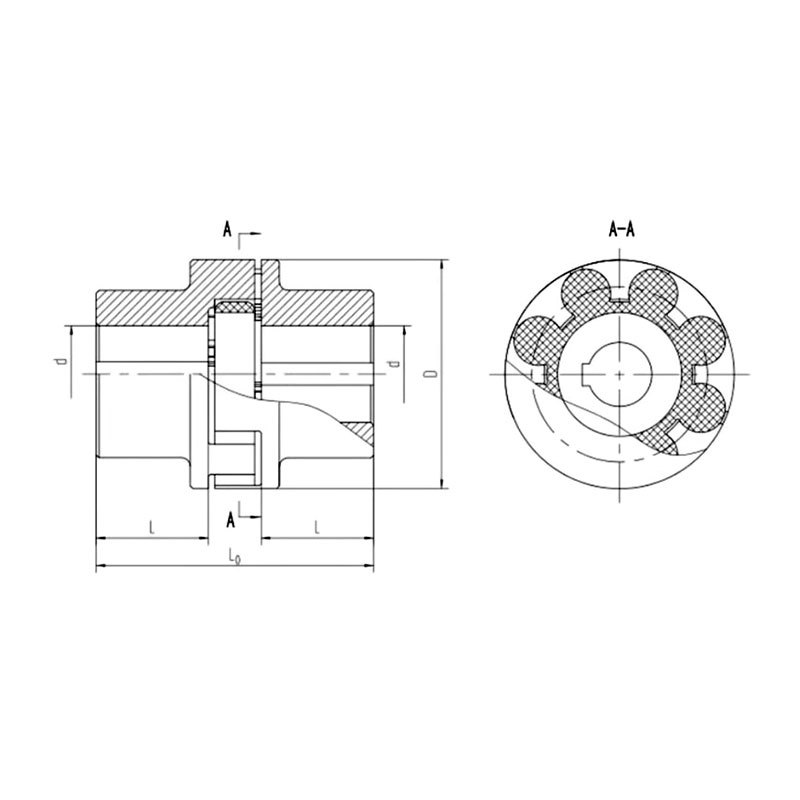

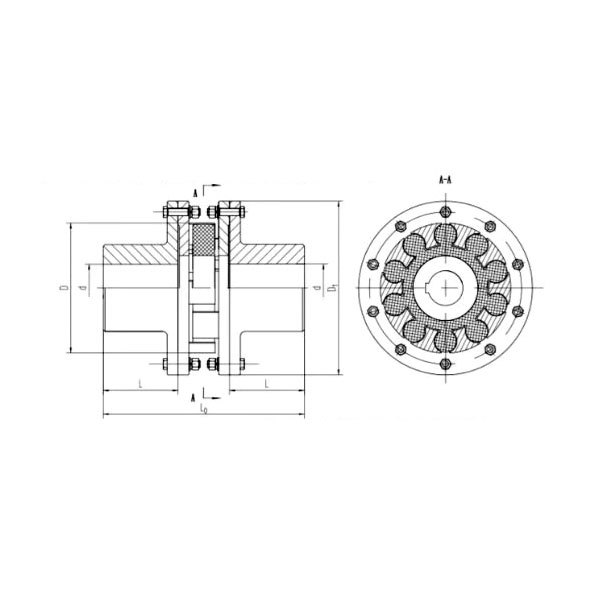

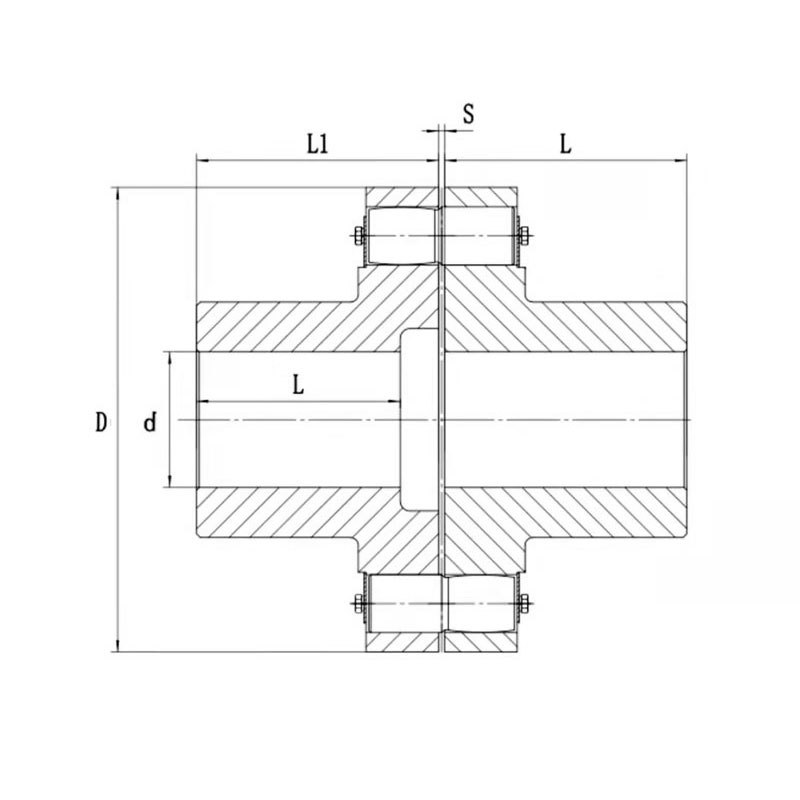

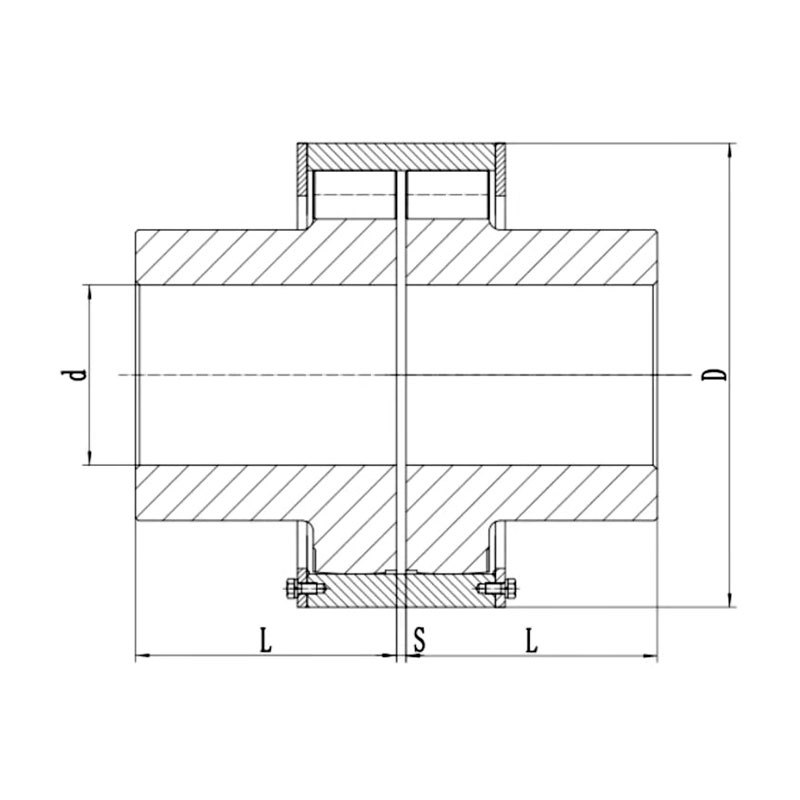

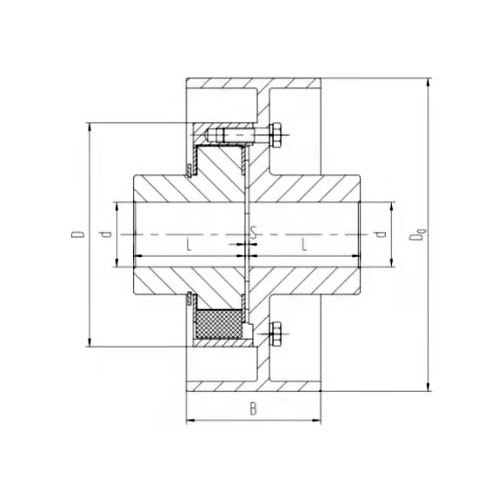

The WGT intermediate sleeve-type drum gear coupling is suitable for applications involving long-distance connections. The structural configuration is shown in Figure 4.6, and the technical and dimensional parameters are listed in Table 4-4.

Figure 4.6 WGT Type Spherical Tooth Coupling

Note: There are two options available for the cover plate.

Table 4-4: Technical Parameters and Main Dimensions of WGT Type Spherical Tooth Coupling

| Model | Nominal torque Tn KN · m |

Permissible rotational speed [n] r/min |

Shaft hole diameter d | Shaft hole length L | D | H min |

C | e | Quality m Kg |

Moment of inertia l Kg · m² |

Lubricant amount Kg |

The mass m of each additional 10 mm added to the intermediate sleeve Kg |

The moment of inertia increases by 10 mm for each additional intermediate sleeve. Quantity 1 Kg · m² |

Intermediate inertia moment la m 4 |

|

| Y | J 1 | ||||||||||||||

| mm | |||||||||||||||

| WGT1 | 0.8 | 7500 | 12, 14 | 32 | - | 122 | 75 | 3 | 30 | 5.66 | 0.008 | 0.085 | 0.088 | 0.00011 | 7.1X105 |

| 16, 18, 19 | 42 | - | |||||||||||||

| 20, 22, 24 | 52 | - | |||||||||||||

| 25, 28 | 62 | 44 | |||||||||||||

| 30, 32, 35, 38 | 82 | 60 | |||||||||||||

| 40, 42 | 112 | 84 | |||||||||||||

| WGT2 | 1.4 | 6300 | 22, 24 | 52 | - | 150 | 80 | 3 | 30 | 9.78 | 0.0021 | 0.09 | 0.13 | 0.00022 | 1.4X106 |

| 25, 8 | 62 | - | |||||||||||||

| 30, 32, 35, 38 | 82 | 60 | |||||||||||||

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | |||||||||||||

| WGT3 | 2.8 | 5500 | 22, 24 | 52 | - | 170 | 80 | 3 | 30 | 16.7 | 0.047 | 0.17 | 0.16 | 0.00041 | 2.7X106 |

| 25, 28 | 62 | - | |||||||||||||

| 30, 32, 35, 38 | 82 | 60 | |||||||||||||

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | |||||||||||||

| 60, 63 | 142 | 107 | |||||||||||||

| WGT4 | 5 | 4800 | 30, 32, 35, 38 | 82 | - | 200 | 100 | 3 | 30 | 25.6 | 0.098 | 0.25 | 0.2 | 0.0008 | 5.2X106 |

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | |||||||||||||

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||||

| 80 | 172 | 132 | |||||||||||||

| WGT5 | 8 | 4300 | 30, 32, 35, 38 | 82 | - | 225 | 100 | 3 | 30 | 35 | 0.175 | 0.35 | 0.23 | 0.0012 | 7.9X106 |

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | |||||||||||||

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||||

| 80, 85, 90 | 172 | 132 | |||||||||||||

Table 4-4: Technical Parameters and Main Dimensions of WGT Type Spherical Tooth Coupling

| Model | Nominal torque Tn KN · m |

Permissible rotational speed [n] r/min |

Shaft hole diameter d | Shaft hole length L | D | H min |

C | e | Quality m Kg |

Moment of inertia l Kg · m² |

Lubricant amount Kg |

The mass m of each additional 10 mm added to the intermediate sleeve Kg |

The moment of inertia increases by 10 mm for each additional intermediate sleeve. Quantity 1 Kg · m² |

Intermediate inertia moment la m 4 |

|

| Y | J 1 | ||||||||||||||

| mm | |||||||||||||||

| WGT6 | 11.2 | 4000 | 32, 35, 38 | 82 | - | 245 | 100 | 5 | 30 | 51.6 | 0.295 | 0.4 | 0.26 | 0.0017 | 1.1X107 |

| 40, 42, 45, 48, 50, 55, 56 | 112 | - | |||||||||||||

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||||

| 80, 85, 90, 95 | 172 | 132 | |||||||||||||

| 100 | 212 | 167 | |||||||||||||

| WGT7 | 16 | 3500 | 32, 35, 38 | 82 | - | 272 | 120 | 5 | 30 | 68.6 | 0.53 | 0.6 | 0.32 | 0.003 | 1.9X107 |

| 40, 42, 45, 48, 50, 55, 56 | 112 | - | |||||||||||||

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||||

| 80, 85, 90, 95 | 172 | 132 | |||||||||||||

| 100, 110 | 212 | 167 | |||||||||||||

| WGT8 | 22.4 | 3250 | 55, 56 | 112 | - | 290 | 120 | 5 | 30 | 79.5 | 0.71 | 0.75 | 0.32 | 0.003 | 2.8X107 |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||||

| 80, 85, 90, 95 | 172 | 132 | |||||||||||||

| 100, 110, 120, 125 | 212 | 167 | |||||||||||||

| WGT9 | 28 | 3000 | 65, 70, 71, 75 | 142 | 107 | 315 | 155 | 5 | 30 | 106.5 | 1.05 | 1 | 0.42 | 0.0045 | 3.6X107 |

| 80, 85, 90, 95 | 172 | 132 | |||||||||||||

| 100, 110, 120, 125 | 212 | 167 | |||||||||||||

| 130, 140 | 252 | 202 | |||||||||||||

| WGT10 | 45 | 2600 | 75 | 142 | - | 355 | 155 | 5 | 30 | 158.8 | 1.87 | 1.3 | 0.46 | 0.0064 | 5.1X107 |

| 80, 85, 90, 95 | 172 | 132 | |||||||||||||

| 100, 110, 120, 125 | 212 | 167 | |||||||||||||

| 130, 140, 150 | 252 | 202 | |||||||||||||

| 160 | 302 | 242 | |||||||||||||

Table 4-4: Technical Parameters and Main Dimensions of WGT Type Spherical Tooth Coupling

| Model | Nominal torque Tn KN · m |

Permissible rotational speed [n] r/min |

Shaft hole diameter d | Shaft hole length L | D | H min |

C | e | Quality m Kg |

Moment of inertia l Kg · m² |

Lubricant amount Kg |

The mass m of each additional 10 mm added to the intermediate sleeve Kg |

The moment of inertia increases by 10 mm for each additional intermediate sleeve. Quantity 1 Kg · m² |

Intermediate inertia moment la m 4 |

|

| Y | J 1 | ||||||||||||||

| mm | |||||||||||||||

| WGT11 | 63 | 2300 | 85, 90, 95 | 172 | - | 412 | 175 | 8 | 40 | 216.6 | 3.71 | 1.6 | 0.52 | 0.0091 | 1.1X108 |

| 100, 110, 120, 125 | 212 | 167 | |||||||||||||

| 130, 140, 150 | 252 | 202 | |||||||||||||

| 160, 170, 180 | 302 | 242 | |||||||||||||

| WGT12 | 90 | 2100 | 120, 125 | 212 | 167 | 440 | 205 | 8 | 40 | 305.3 | 6.43 | 2.6 | 0.71 | 0.015 | 1.4X108 |

| 130, 140, 150 | 252 | 202 | |||||||||||||

| 160, 170, 180 | 302 | 242 | |||||||||||||

| 190, 200 | 352 | 282 | |||||||||||||

| WGT13 | 125 | 1800 | 140, 150 | 252 | 202 | 490 | 205 | 8 | 50 | 394.5 | 10.58 | 3.3 | 0.83 | 0.024 | 2.3X108 |

| 160, 170, 180 | 302 | 242 | |||||||||||||

| 190, 200, 220 | 352 | 282 | |||||||||||||

| WGT14 | 180 | 1700 | 160, 170, 180 | 302 | 242 | 545 | 240 | 10 | 50 | 529.5 | 17.72 | 4.8 | 0.96 | 0.037 | 2.8X108 |

| 190, 200, 220 | 352 | 282 | |||||||||||||

| 240, 250, 260 | 410 | 330 | |||||||||||||

| WCT15 | 250 | 1600 | 160, 170, 180 | 302 | 242 | 580 | 240 | 10 | 50 | 684.5 |

25.25 | 5 | 1.03 | 0.044 | 3.3X108 |

| 190, 200, 220 | 352 | 282 | |||||||||||||

| 240, 250, 260 | 410 | 330 | |||||||||||||

| 280 | 470 | 380 | |||||||||||||

| WGT16 | 315 | 1450 | 180 | 302 | 242 | 650 | 240 | 12 | 50 | 948.2 | 43.7 | 7 | 1.5 | 0.072 | 5.6X108 |

| 190, 200, 220 | 352 | 282 | |||||||||||||

| 240, 250, 260 | 410 | 330 | |||||||||||||

| 280, 300 | 470 | 380 | |||||||||||||

| WGT17 | 400 | 1300 | 200, 220 | 352 | 282 | 690 | 280 | 12 | 50 | 1059 | 57.37 | 8 | 2.5 | 0.16 | 1.0X109 |

| 240, 250, 260 | 410 | 330 | |||||||||||||

| 280, 300, 320 | 470 | 380 | |||||||||||||

Table 4-4: Technical Parameters and Main Dimensions of WGT Type Spherical Tooth Coupling

| Model | Nominal torque Tn KN · m |

Permissible rotational speed [n] r/min |

Shaft hole diameter d | Shaft hole length L | D | H min |

C | e | Quality m Kg |

Moment of inertia l Kg · m² |

Lubricant amount Kg |

The mass m of each additional 10 mm added to the intermediate sleeve Kg |

The moment of inertia increases by 10 mm for each additional intermediate sleeve. Quantity 1 Kg · m² |

Intermediate inertia moment la m 4 |

|

| Y | J 1 | ||||||||||||||

| mm | |||||||||||||||

| WGT18 | 500 | 1200 | 220 | 352 | 282 | 750 | 280 | 12 | 60 | 1399 | 59.37 | 10 | 2.76 | 0.22 | 1.5X109 |

| 240, 250, 260 | 410 | 330 | |||||||||||||

| 280, 300, 320 | 470 | 380 | |||||||||||||

| 340, 360 | 550 | 450 | |||||||||||||

| WGT19 | 630 | 1100 | 240, 250, 260 | 410 | 330 | 775 | 350 | 12 | 60 | 1544 | 110.2 | 11 | 2.96 | 0.27 | 1.9X109 |

| 280, 300, 320 | 470 | 380 | |||||||||||||

| 340, 360, 380 | 550 | 450 | |||||||||||||

| WGT20 | 800 | 1000 | 260 | 410 | 330 | 825 | 350 | 14 | 60 | 2099 | 166.1 | 13 | 3.16 | 0.32 | 2.2X109 |

| 280, 300, 320 | 470 | 380 | |||||||||||||

| 340, 360, 380 | 550 | 450 | |||||||||||||

| 400 | 650 | 540 | |||||||||||||

| WGT21 | 900 | 950 | 280, 300, 320 | 470 | 380 | 925 | 350 | 14 | 60 | 2482 | 242.7 | 20 | 4.2 | 0.5 | 3.2X109 |

| 340, 360, 380 | 550 | 450 | |||||||||||||

| 400, 420, 440 | 650 | 540 | |||||||||||||

| WGT22 | 1000 | 900 | 320 | 470 | 380 | 950 | 400 | 14 | 60 | 2797 | 299.2 | 26 | 4.47 | 0.59 | 3.7X109 |

| 340, 360, 380 | 550 | 450 | |||||||||||||

| 400, 420, 440, 450, 460 | 650 | 540 | |||||||||||||

| WGT23 | 1120 | 880 | 360, 380 | 550 | 450 | 1030 | 400 | 14 | 60 | 3183 | 388.8 | 29 | 4.77 | 0.88 | 5.6X109 |

| 400, 420, 440, 450, 460, 480, 500 | 650 | 540 | |||||||||||||

| WGT24 | 1400 | 850 | 380 | 550 | 450 | 1060 | 400 | 16 | 70 | 3801 | 482 | 32 | 6.07 | 1.02 | 6.5X109 |

| 400, 420, 440, 450, 460, 480, 500 | 650 | 540 | |||||||||||||

| 520 | 800 | 680 | |||||||||||||

Note: 1. The moment of inertia and mass are calculated based on the J1 type, including the shaft extension.

2. The shaft hole length is recommended to be of Type J1.

3. e is the dimension required for replacing the seal.

4. The allowable rotational speed [n] refers to the value when the equivalent angular misalignment is ≤0.25°. If the equivalent angular misalignment exceeds 0.25°, please consult our company’s technical staff for selection guidance.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products