NUPEX Combination Flexible Coupling

Category

Contact Information

Detailed introduction

Product Features

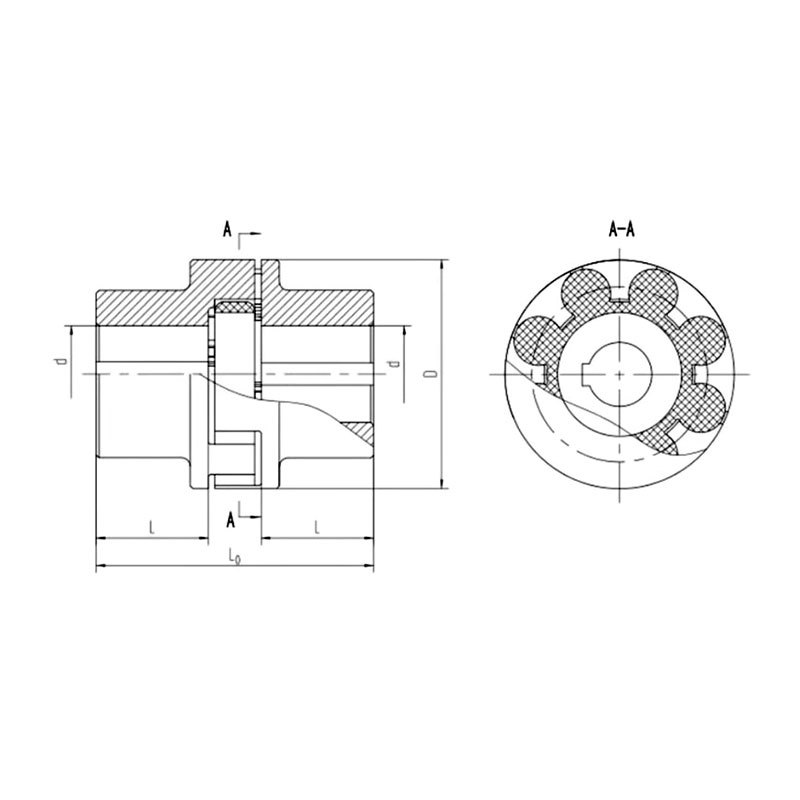

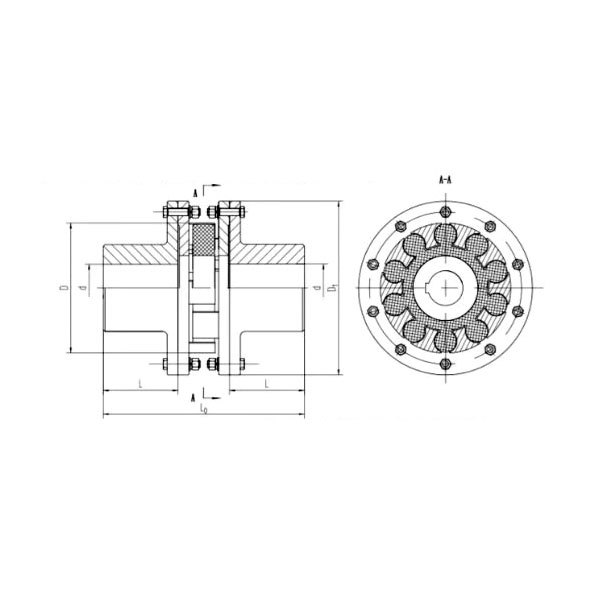

The NUPEX combination flexible coupling is a high-performance coupling developed and launched onto the market in 2000 by Schenck Power specifically for the characteristics of variable-frequency drive units. After successful application at the Jinxi Petrochemical Plant, more than 300 units have been installed to date, all operating smoothly and delivering excellent performance. Its structural features are as follows:

1. Supported by new U.S. technology, featuring an NUP+ diaphragm combination design.

2. Finite element equal-strength design—lighter, more convenient, and safer.

3. Automatic self-aligning feature can accommodate misalignment in all directions of the unit, requiring only rough alignment during installation.

4. The polyurethane rubber sleeve features pressure resistance, self-lubrication, and permanent elasticity; the three stiffness levels are selected based on torque calculation results.

5. Built-in joint bearing provides radial support up to 5 tons, completely eliminating the need for intermediate radial supports.

6. The deflection stiffness of the intermediate shaft can be adjusted to avoid critical rotational speeds and improve the dynamic characteristics of the unit’s rotor.

7. Fully absorbs variable-frequency harmonic impacts, provides shock absorption, and operates silently.

8.3 DH phase magnetic strip and counterweight screw holes allow for correction of shaft system imbalance.

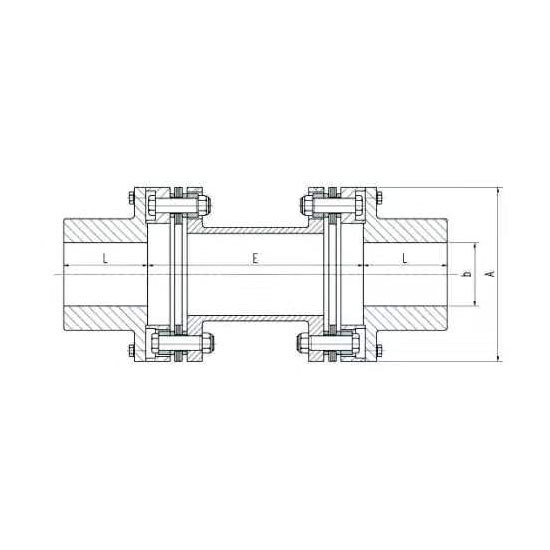

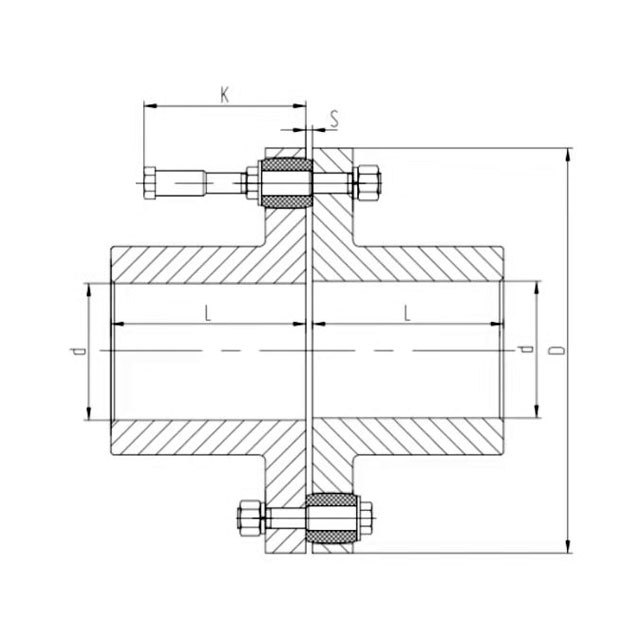

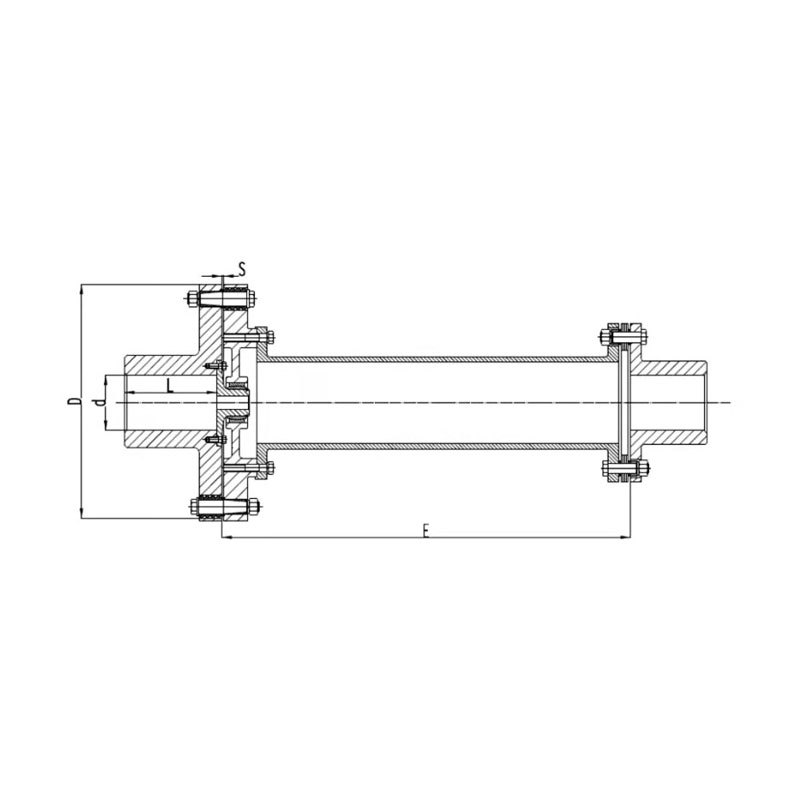

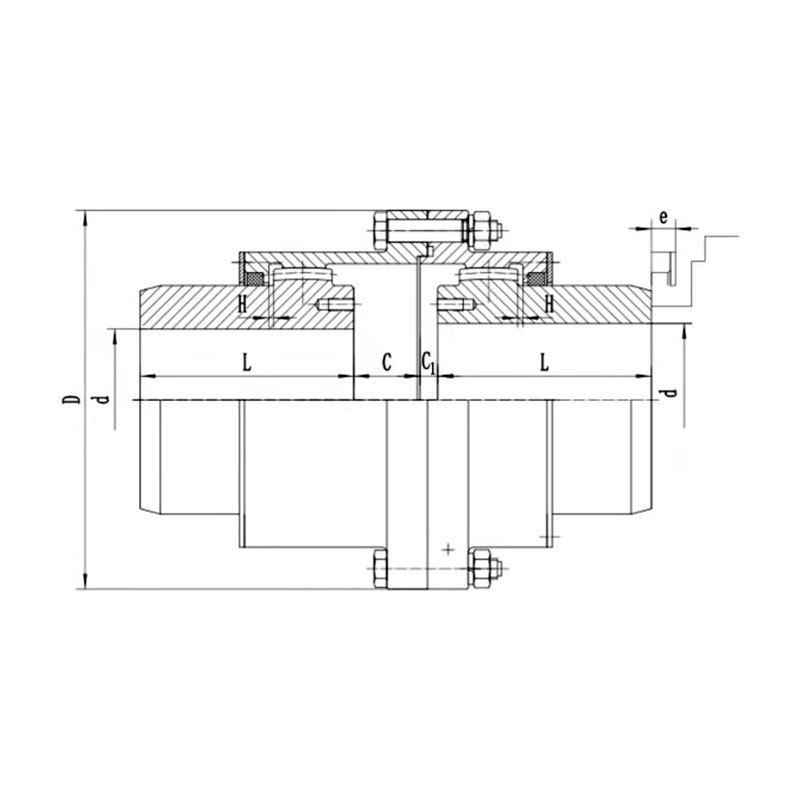

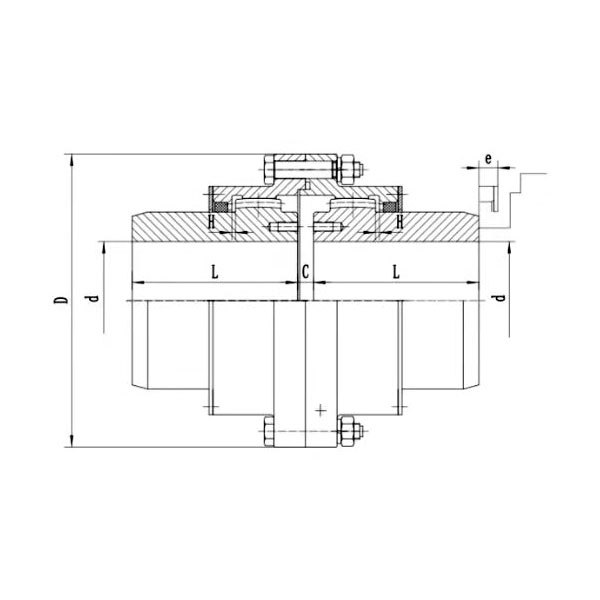

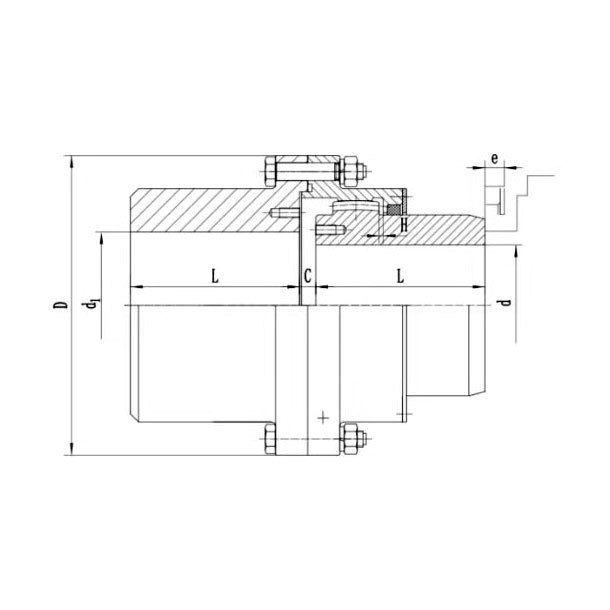

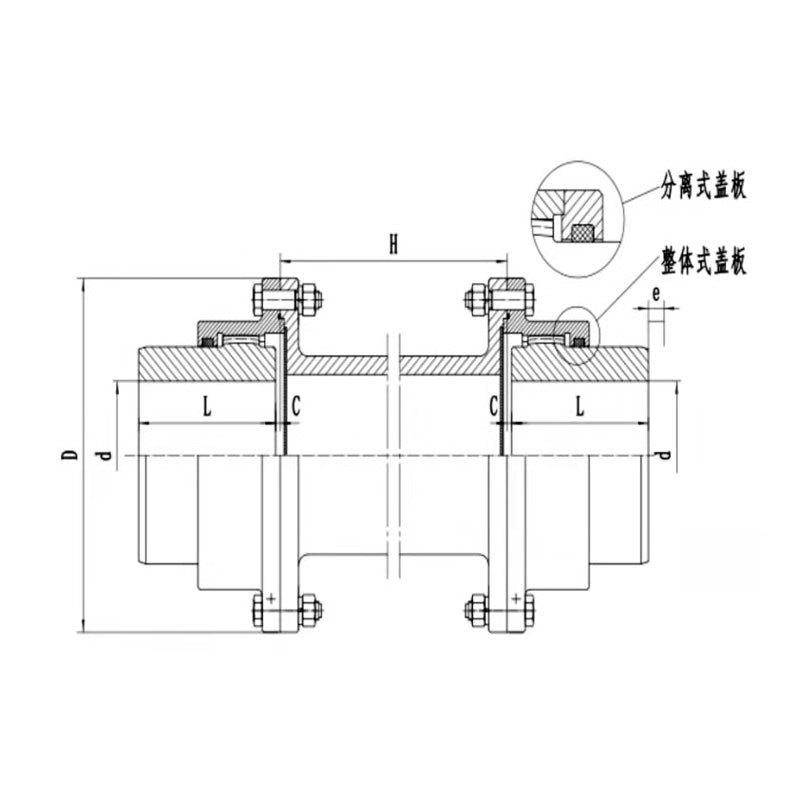

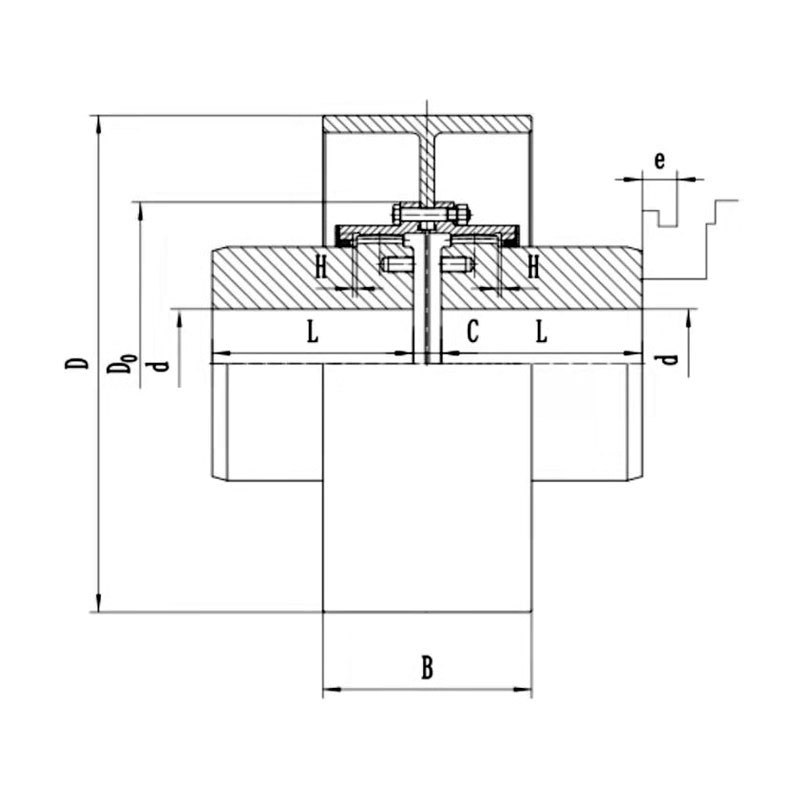

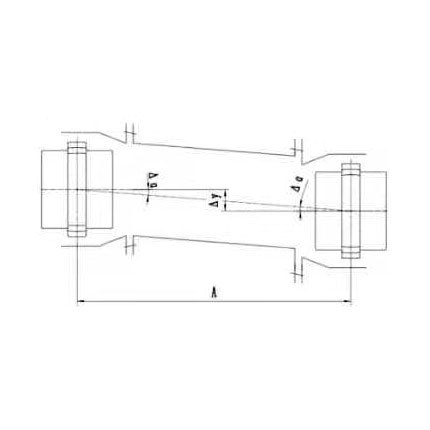

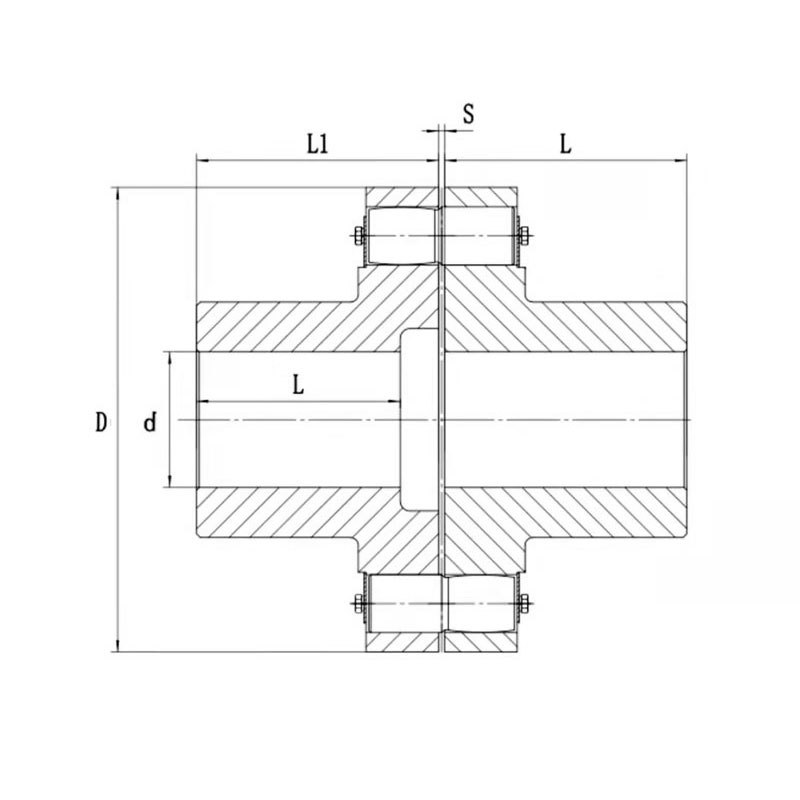

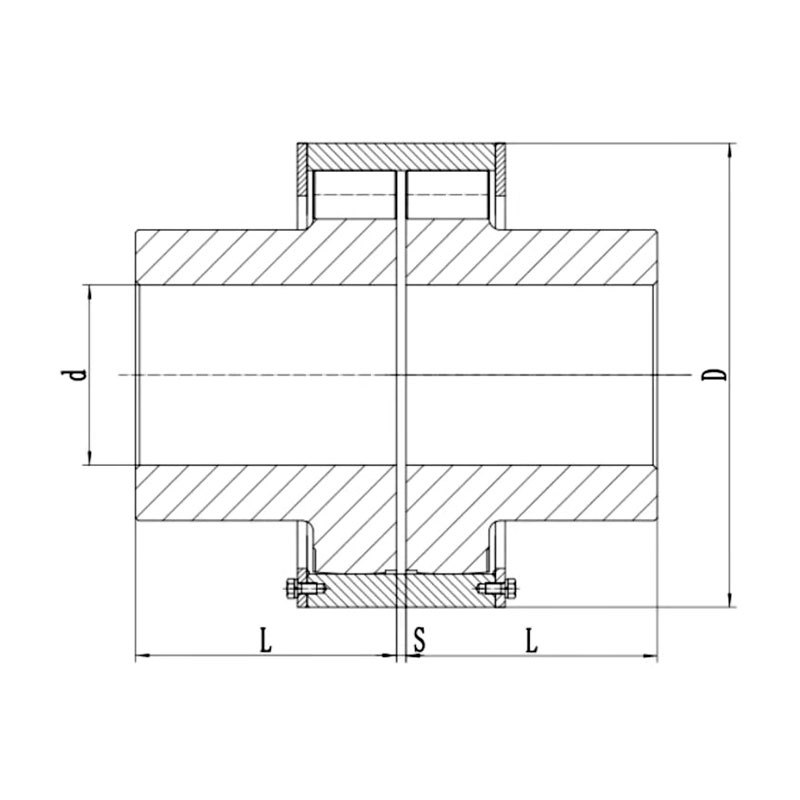

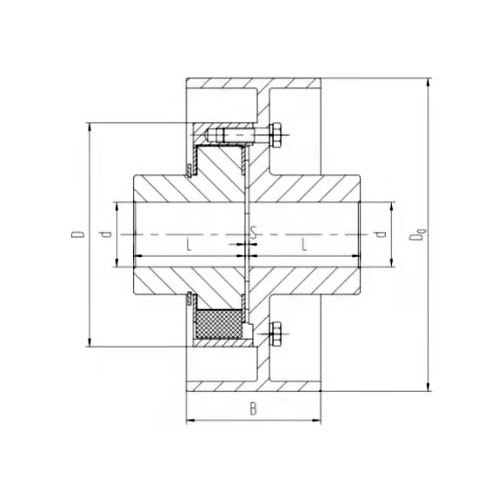

Figure 3.2 NUPEX Composite Elastic Coupling

Table 3-2: Technical Parameters and Main Dimensions of the NUPEX Composite Elastic Coupling

| Model | Rated torque Mr. N.m |

Peak torque City of Tp N.m |

Permissible Rotational Speed revolutions per minute |

D mm |

d Max mm |

S mm |

L mm |

Moment of inertia Kg·m² |

Torsional stiffness MNm/rad |

Misalignment absorption capability | |

| Axial mm |

Angular direction ° |

||||||||||

| NUPEX162 | 920 | 1800 | 4300 | 162 | 75 | 4 | 60 | 0.132 | 0.02 | 4 | 1.5 |

| NUPEX178 | 1000 | 2100 | 3800 | 178 | 80 | 4 | 70 | 0.14 | 0.036 | 4 | 1.5 |

| NUPEX198 | 1200 | 2300 | 3400 | 198 | 90 | 4 | 80 | 0.148 | 0.054 | 5 | 1.5 |

| NUPEX228 | 1800 | 3600 | 3000 | 228 | 100 | 5 | 90 | 0.159 | 0.114 | 5 | 1.5 |

| NUPEX252 | 2600 | 5200 | 2700 | 252 | 120 | 5 | 100 | 0.17 | 0.19 | 6 | 1.8 |

| NUPEX285 | 4500 | 9000 | 2400 | 285 | 130 | 5 | 110 | 0.179 | 0.35 | 6 | 1.8 |

| NUPEX320 | 5500 | 11000 | 2100 | 320 | 140 | 5 | 125 | 0.19 | 0.46 | 6 | 1.8 |

| NUPEX360 | 9000 | 18000 | 1900 | 360 | 160 | 5 | 140 | 0.2 | 0.13 | 7 | 1.8 |

| NUPEX400 | 13000 | 27000 | 1700 | 400 | 170 | 6 | 160 | 0.212 | 1.9 | 7 | 2.5 |

| NUPEX450 | 22000 | 44000 | 1500 | 450 | 195 | 6 | 180 | 0.22 | 3.6 | 7 | 2.5 |

| NUPEX500 | 27000 | 54000 | 1350 | 500 | 220 | 6 | 200 | 0.23 | 5.8 | 8 | 2.5 |

| NUPEX560 | 42000 | 84000 | 1200 | 560 | 235 | 6 | 220 | 0.24 | 10.4 | 8 | 2.5 |

| NUPEX630 | 48000 | 95000 | 1050 | 630 | 250 | 6 | 240 | 0.25 | 16 | 8 | 2.5 |

| NUPEX710 | 70000 | 142000 | 950 | 710 | 270 | 6 | 260 | 0.26 | 30 | 8 | 3.0 |

| NUPEX800 | 81000 | 162000 | 850 | 800 | 295 | 6 | 290 | 0.27 | 47 | 10 | 3.0 |

| NUPEX900 | 123000 | 245000 | 750 | 900 | 320 | 8 | 320 | 0.28 | 85 | 10 | 3.0 |

| NUPEX1000 | 140000 | 280000 | 680 | 1000 | 350 | 8 | 350 | 0.29 | 125 | 10 | 3.0 |

Note: The shaft hole length L is a recommended value; users may specify their own values.

The values for the moment of inertia and torsional stiffness are given for E = 1 m; the final values are shown in the drawing.

The axis spacing E, as required by the user, shall be ≤10 m.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products

T-type and D-type diaphragm couplings

NUP New Elastic Sleeve Pin Coupling

NUPEX Combination Flexible Coupling

GCLD Type Spherical Tooth Coupling

GIICL-type drum-type gear coupling

GIICLZ-type drum-type gear coupling

WGT Type Drum-Type Gear Coupling

NGCL Type Spherical Tooth Coupling

Compensating capacity for relative displacement between the two shafts of a drum-type gear coupling

LM-type梅花-shaped elastic coupling

LMS-type梅花-shaped elastic coupling

Lz-type Elastic Pin-and-Tooth Coupling

LZZ Type Elastic Pin-and-Block Coupling with Brake Wheel

Shenyang Shenke Power Machinery Co,. Ltd.

Address: No. 34 Jia, Kaifa Avenue, Tiexi Economic and Technological Development Zone, Shenyang

Email:sincflex@vip.163.com

Phone:+86 24 25830257

Mobile phone:+86 15940017261

Fax: +86 24 25308993

WeChat contact