Diaphragm coupling

Category

Contact Information

Detailed introduction

Product features:

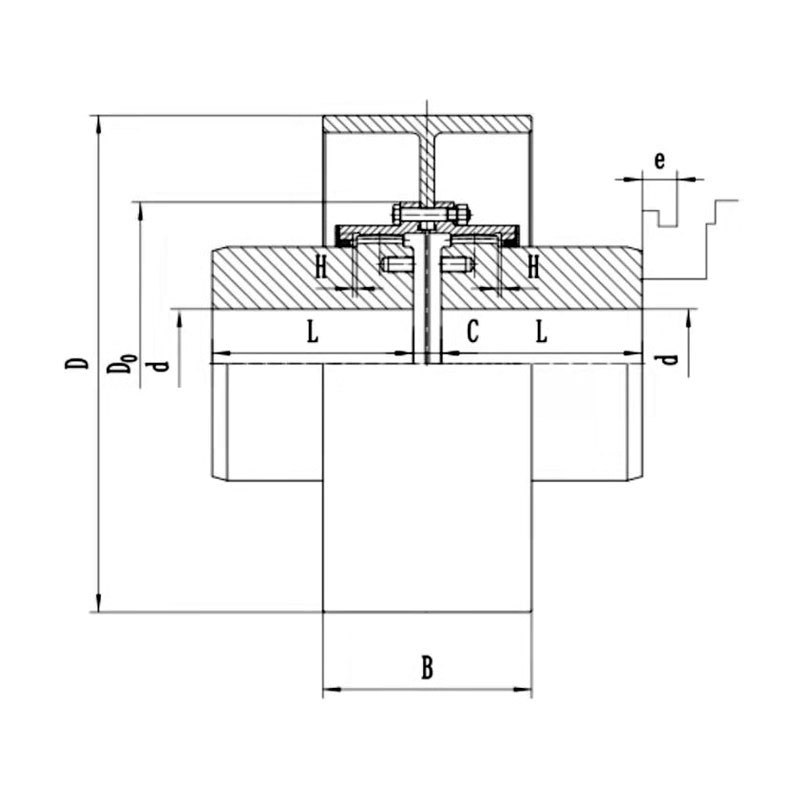

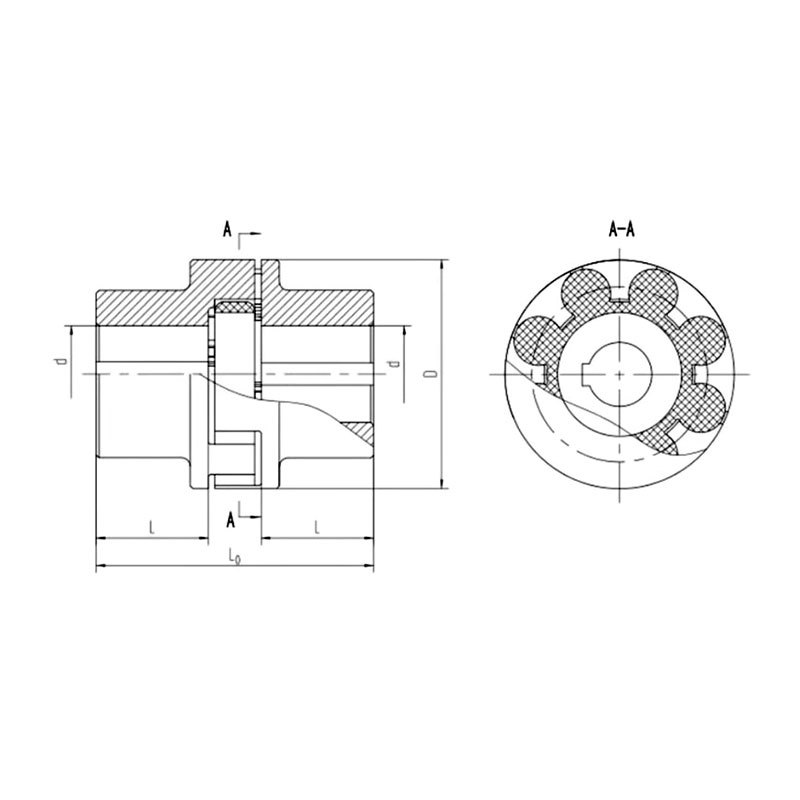

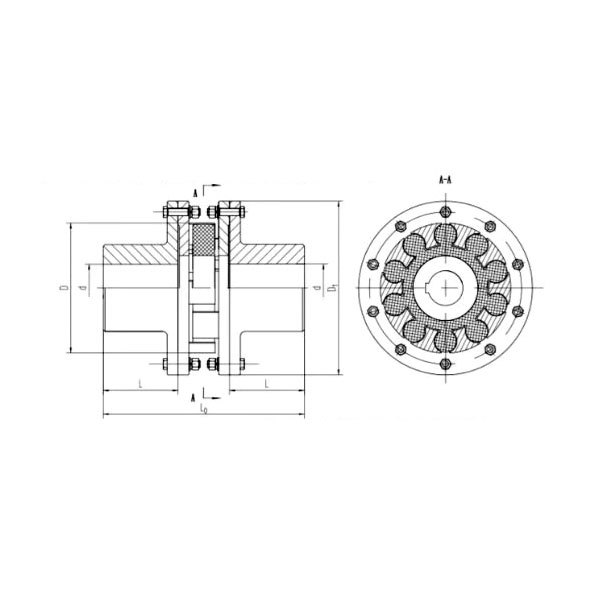

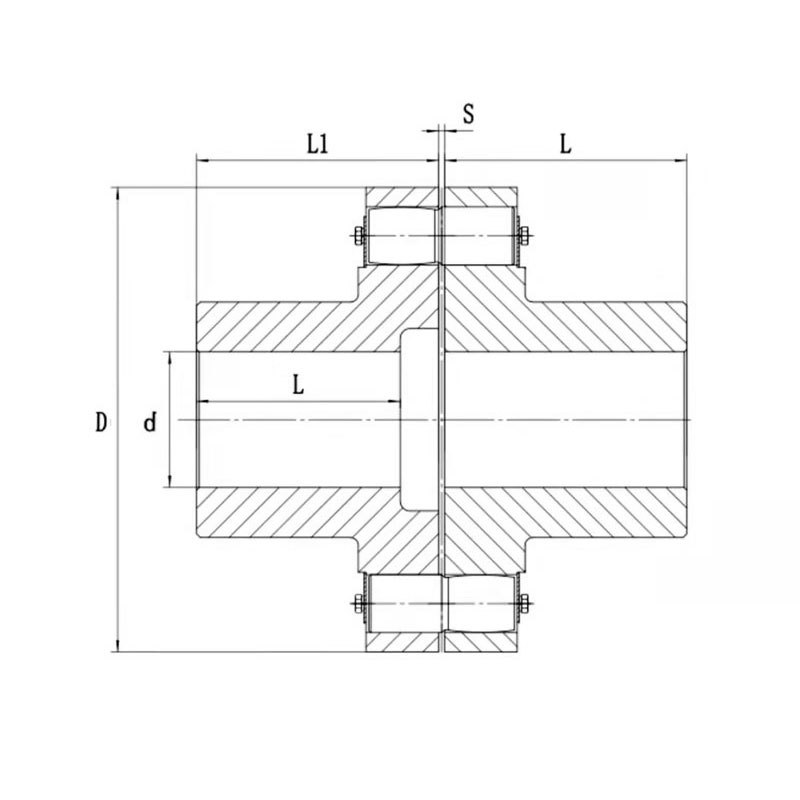

The diaphragm coupling is a metallic flexible coupling that can compensate for deviations in the radial, axial, and angular directions. Compared to conventional diaphragm couplings, it features a compact structure, strong corrosion resistance inherent to the diaphragm disc itself, high load-carrying capacity, light weight, and suitability for high rotational speeds.

Application scenarios:

Suitable for industries such as compressors, high-speed turbines, fans, and pumps, and also applicable to various high-speed shaft transmission systems in sectors including petroleum, chemical engineering, and general machinery.

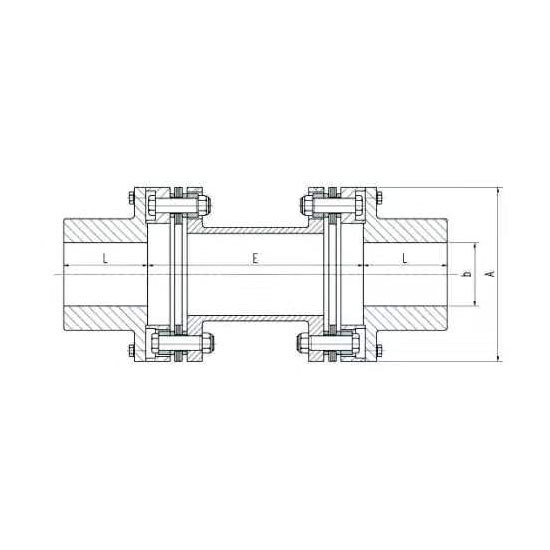

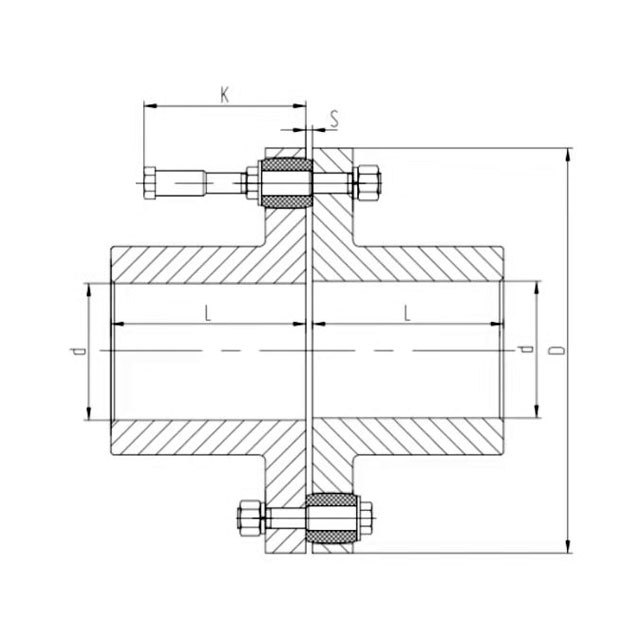

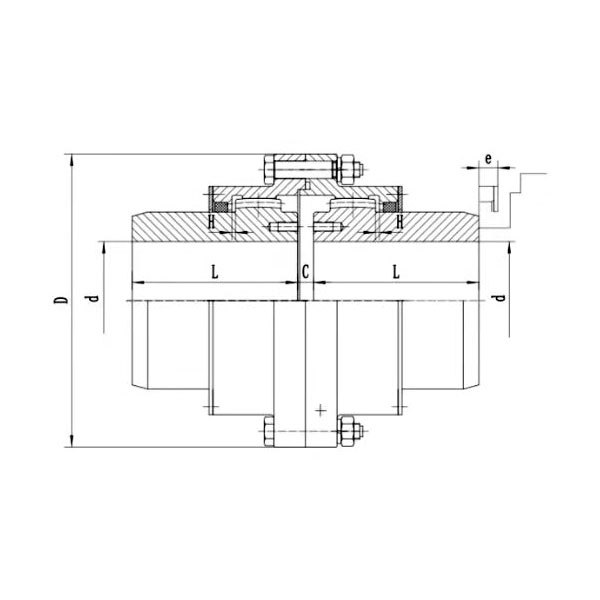

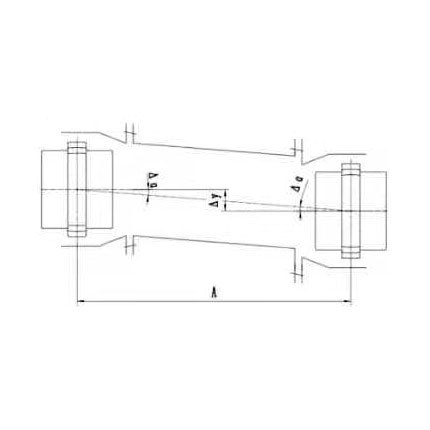

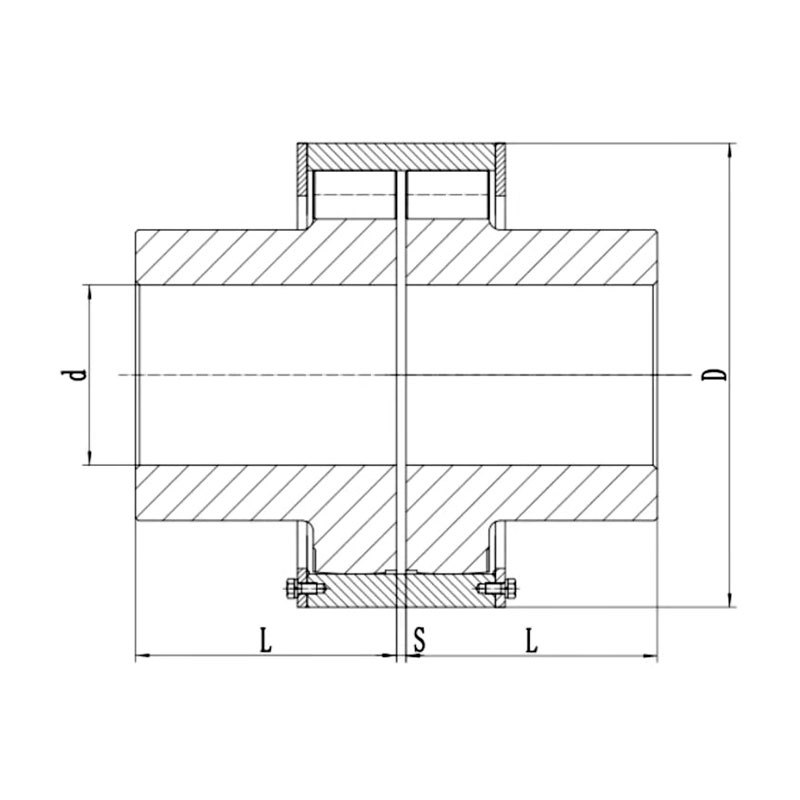

SK3 Series Diaphragm Coupling

It can compensate for angular misalignment of up to 1/3°. If a smaller overall dimension is required, you can choose the SK4 or SK5 series.

Figure: SK3 Series Diaphragm Coupling

Technical Parameters and Main Dimensions of the SK3 Series Diaphragm Couplings

| Model | Nominal torque kN·m |

Peak torque kN·m |

Instantaneous torque kN·m |

Maximum rotational speed revolutions per minute |

Maximum shaft hole d | D | L | H | Moment of inertia kg·m² |

Weight Kilogram |

Misalignment absorption capability | |

| mm | Axial mm | Angular. | ||||||||||

| SK388 | 0.27 | 0.36 | 0.48 | 60000 | 40 | 88 | 50 | 60 | 0.002 | 2.52 | 0.8 | 0.33 |

| SK3110 | 0.62 | 0.85 | 1.12 | 45000 | 50 | 110 | 60 | 80 | 0.005 | 4.71 | 1.0 | 0.33 |

| SK3160 | 2.25 | 2.96 | 3.98 | 32000 | 75 | 160 | 90 | 115 | 0.03 | 12 | 1.5 | 0.33 |

| SK3186 | 4.52 | 5.95 | 7.98 | 28000 | 95 | 186 | 100 | 140 | 0.07 | 19.9 | 2.0 | 0.33 |

| SK3238 | 9.98 | 13.2 | 17.5 | 22000 | 125 | 238 | 140 | 190 | 0.28 | 45 | 2.5 | 0.33 |

| SK3285 | 19.98 | 26.5 | 35.2 | 18000 | 155 | 285 | 180 | 235 | 0.75 | 81.5 | 3.2 | 0.33 |

| SK3336 | 35.6 | 47 | 62.5 | 16000 | 190 | 336 | 200 | 285 | 2 | 140 | 4.0 | 0.33 |

| SK3380 | 49.95 | 66.4 | 88.8 | 14000 | 215 | 380 | 240 | 325 | 3.7 | 202 | 4.5 | 0.33 |

| SK3436 | 79.96 | 105.8 | 142.2 | 12000 | 250 | 436 | 280 | 380 | 7.8 | 320 | 5.1 | 0.33 |

| SK3485 | 112.3 | 147.5 | 198.6 | 11000 | 280 | 485 | 320 | 425 | 13.5 | 432 | 5.7 | 0.33 |

| SK3576 | 200 | 265.5 | 352 | 9000 | 340 | 576 | 390 | 510 | 35 | 750 | 7.0 | 0.33 |

| SK3672 | 224.5 | 298.6 | 395.6 | 6500 | 400 | 672 | 450 | 600 | 80 | 1250 | 7.8 | 0.33 |

| SK3835 | 448.8 | 598.2 | 791.3 | 5000 | 490 | 835 | 550 | 745 | 230 | 2350 | 9.8 | 0.33 |

| SK31010 | 800.2 | 1058 | 1397 | 4000 | 600 | 1010 | 650 | 910 | 620 | 4200 | 12.0 | 0.33 |

| SK31165 | 1398 | 1856 | 3272 | 3600 | 700 | 1165 | 780 | 1050 | 1270 | 6400 | 14.0 | 0.33 |

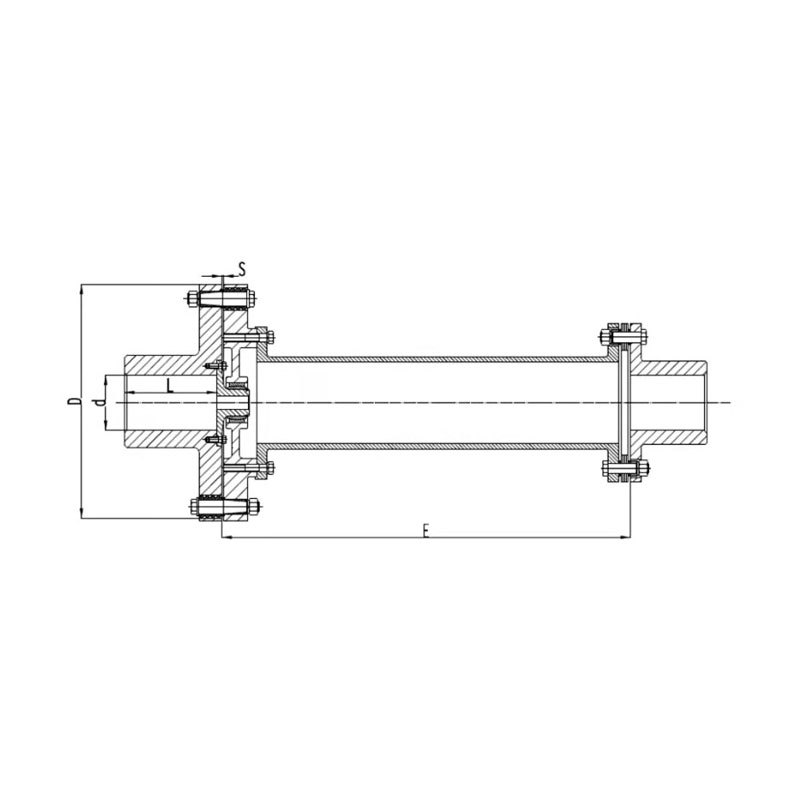

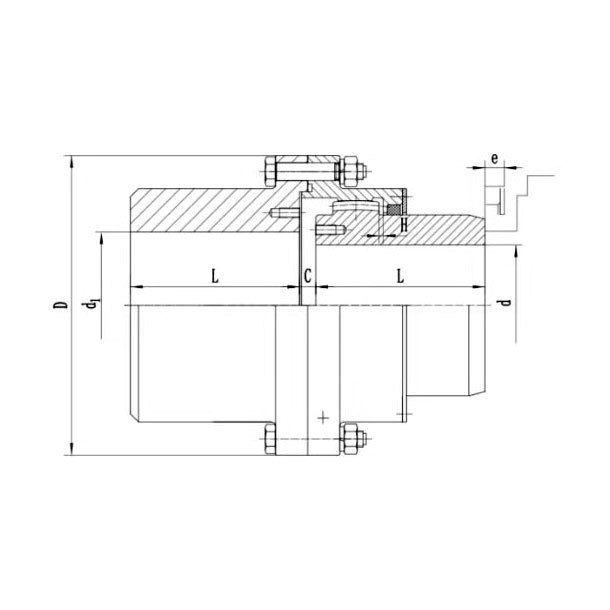

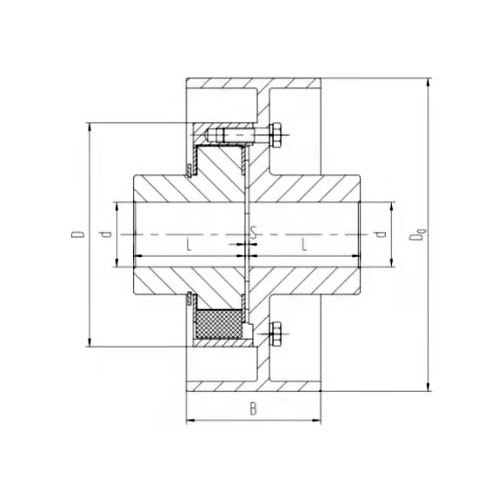

SK4 Series Diaphragm Coupling

It can compensate for angular misalignment of up to 1/4°. If a smaller overall dimension is required, you can choose the SK5 series; if greater compensation capability is needed, you can select the SK3 series.

Table SK4: Technical Parameters and Main Dimensions of the Diaphragm Coupling

| Model | Nominal torque kN·m |

Peak torque kN·m |

Instantaneous torque kN·m |

Maximum rotational speed revolutions per minute |

Maximum shaft hole d | D | L | H | Moment of inertia kg·m² |

Weight Kilogram |

Misalignment absorption capability | |

| mm | Axial mm | Angular. | ||||||||||

| SK488 | 0.34 | 0.45 | 0.6 | 60000 | 40 | 88 | 50 | 60 | 0.002 | 2.53 | 0.6 | 0.25 |

| SK4110 | 0.78 | 1.05 | 1.41 | 45000 | 50 | 110 | 60 | 80 | 0.005 | 4.89 | 0.8 | 0.25 |

| SK4160 | 2.78 | 3.7 | 4.96 | 32000 | 75 | 160 | 90 | 115 | 0.031 | 12.8 | 1.2 | 0.25 |

| SK4186 | 5.56 | 7.48 | 9.93 | 28000 | 95 | 186 | 100 | 140 | 0.072 | 20.3 | 1.5 | 0.25 |

| SK4238 | 12.4 | 16.62 | 22 | 22000 | 125 | 238 | 140 | 190 | 0.288 | 46 | 2.0 | 0.25 |

| SK4285 | 25.2 | 33 | 44.3 | 18000 | 155 | 285 | 180 | 235 | 0.772 | 83.2 | 2.5 | 0.25 |

| SK4336 | 44.88 | 60 | 79.2 | 16000 | 190 | 336 | 200 | 285 | 2.02 | 145.7 | 3.1 | 0.25 |

| SK4380 | 62.5 | 82.5 | 110 | 14000 | 215 | 380 | 240 | 325 | 3.75 | 205.4 | 3.5 | 0.25 |

| SK4436 | 98.8 | 132 | 176.5 | 12000 | 250 | 436 | 280 | 380 | 7.96 | 324.1 | 4.1 | 0.25 |

| SK4485 | 140.5 | 185 | 248.7 | 11000 | 280 | 485 | 320 | 425 | 13.72 | 438.6 | 4.5 | 0.25 |

| SK4576 | 249.7 | 330 | 440 | 9000 | 340 | 576 | 390 | 510 | 35.61 | 757.7 | 5.5 | 0.25 |

| SK4672 | 280.2 | 370 | 390 | 6500 | 400 | 672 | 450 | 600 | 80.43 | 1260 | 6.0 | 0.25 |

| SK4835 | 558 | 745 | 985 | 5000 | 490 | 835 | 550 | 745 | 231.1 | 2380 | 7.6 | 0.25 |

| SK41010 | 1118 | 1332 | 1966 | 4000 | 600 | 1010 | 650 | 910 | 622.3 | 4220 | 9.5 | 0.25 |

| SK41165 | 1802 | 2386 | 3183 | 3600 | 700 | 1165 | 780 | 1050 | 1283 | 6420 | 11.0 | 0.25 |

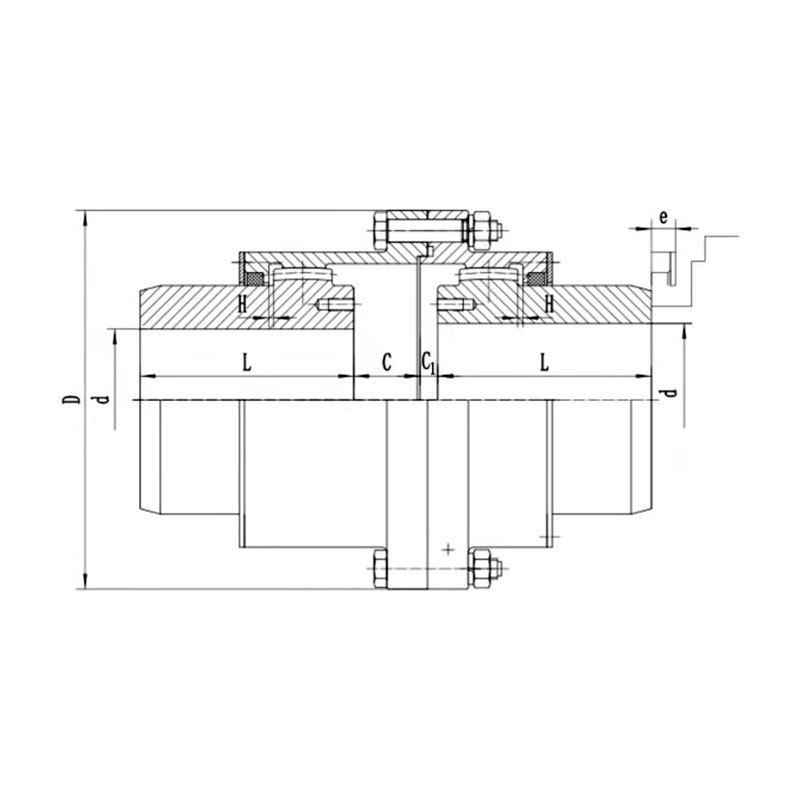

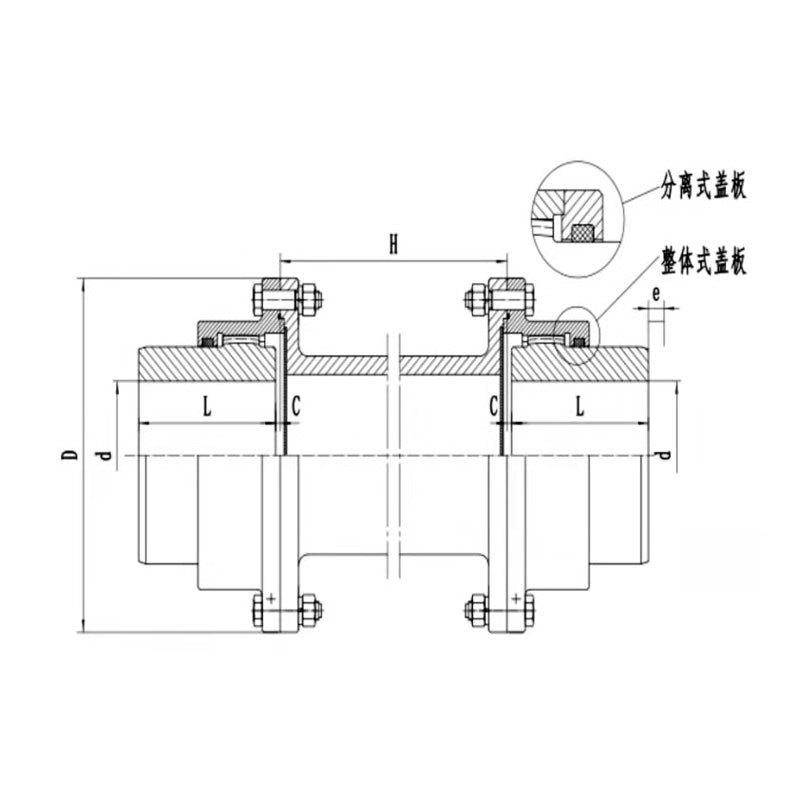

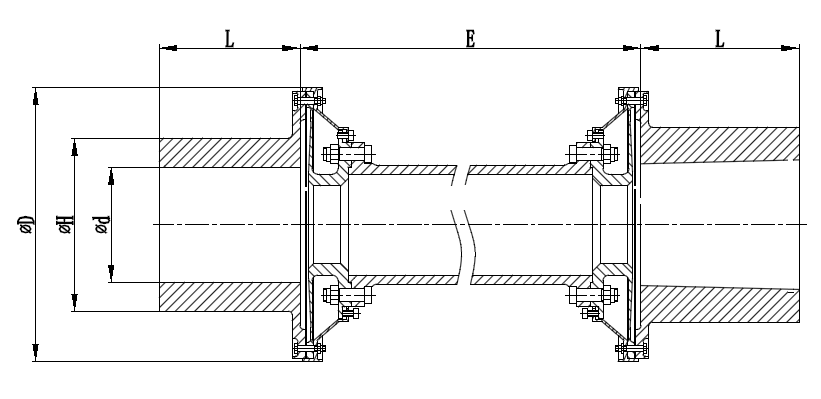

SK5 Disc Coupling with Membrane

It can compensate for angular misalignment of up to 1/5. If a greater compensation capability is required, you can choose the SK3 or SK4 series.

Table SK5: Technical Parameters and Main Dimensions of the Membrane Disc Coupling

| Model | Nominal torque kN·m |

Peak torque kN·m |

Instantaneous torque kN·m |

Maximum rotational speed revolutions per minute |

Maximum shaft hole d | D | L | H | Moment of inertia kg·m² |

Weight Kilogram |

Misalignment absorption capability | |

| mm | Axial mm | Angular. | ||||||||||

| SK588 | 0.48 | 0.65 | 0.85 | 60000 | 40 | 88 | 50 | 60 | 0.002 | 2.82 | 0.4 | 0.2 |

| SK5110 | 1.1 | 1.5 | 1.95 | 45000 | 50 | 110 | 60 | 80 | 0.006 | 5.46 | 0.6 | 0.2 |

| SK5160 | 4 | 5.3 | 7 | 32000 | 75 | 160 | 90 | 115 | 0.032 | 13.5 | 0.8 | 0.2 |

| SK5186 | 8 | 10.5 | 14 | 28000 | 95 | 186 | 100 | 140 | 0.073 | 22.1 | 1.0 | 0.2 |

| SK5238 | 17.7 | 24 | 32 | 22000 | 125 | 238 | 140 | 190 | 0.289 | 47.8 | 1.3 | 0.2 |

| SK5285 | 35.2 | 47.5 | 61.2 | 18000 | 155 | 285 | 180 | 235 | 0.775 | 83.3 | 1.7 | 0.2 |

| SK5336 | 62.5 | 82.8 | 109.8 | 16000 | 190 | 336 | 200 | 285 | 2.08 | 147.2 | 2.1 | 0.2 |

| SK5380 | 88.7 | 120 | 156 | 14000 | 215 | 380 | 240 | 325 | 3.77 | 207.5 | 2.4 | 0.2 |

| SK5436 | 140.2 | 185 | 245.3 | 12000 | 250 | 436 | 280 | 380 | 7.98 | 328.6 | 2.8 | 0.2 |

| SK5485 | 198 | 265 | 349.7 | 11000 | 280 | 485 | 320 | 425 | 13.85 | 441.2 | 3.1 | 0.2 |

| SK5576 | 350 | 470 | 630.4 | 9000 | 340 | 576 | 390 | 510 | 35.72 | 761.3 | 3.8 | 0.2 |

| SK5672 | 400 | 528 | 705.8 | 6500 | 400 | 672 | 450 | 600 | 80.76 | 1265 | 4.2 | 0.2 |

| SK5835 | 802 | 1052 | 1395 | 5000 | 490 | 835 | 550 | 745 | 232.2 | 2385 | 5.3 | 0.2 |

| SK51010 | 1610 | 2119 | 2803 | 4000 | 600 | 1010 | 650 | 910 | 624.4 | 4230 | 6.5 | 0.2 |

| SK51165 | 2495 | 3302 | 4411 | 3600 | 700 | 1165 | 780 | 1050 | 1288 | 6450 | 7.6 | 0.2 |

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products