Wb-type rubber block coupling

Category

Contact Information

Detailed introduction

Product Features

The mechanical rubber coupling can transmit high torque and absorb impact generated by the rotating unit. It requires no lubrication, is easy to install and disassemble, and can operate in harsh environments such as those with moisture, sand, high temperatures, and other adverse conditions. It demands low maintenance and can extend the service life of the equipment.

Application scenarios

Suitable for units with large moment of inertia, significant torque fluctuations, operational impacts, and reciprocating motions.

Wb-type rubber block coupling

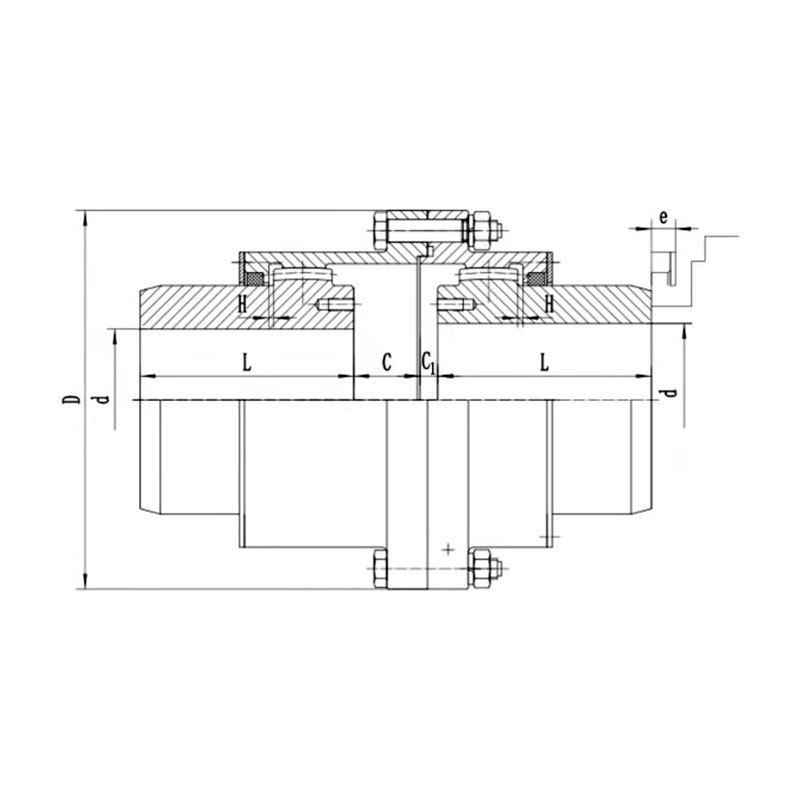

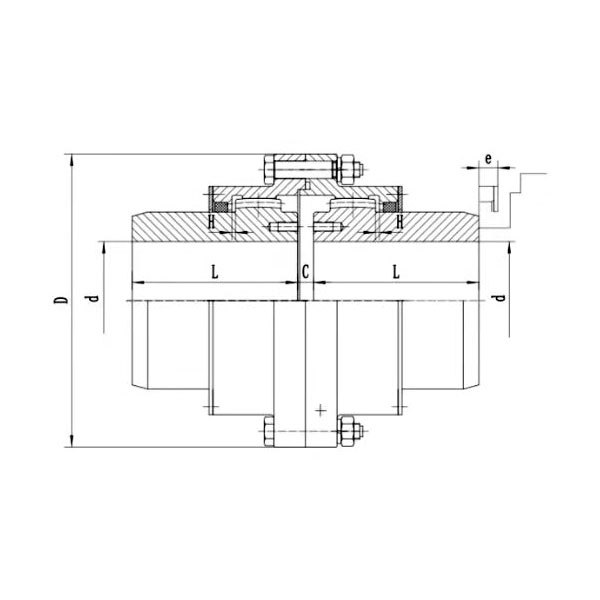

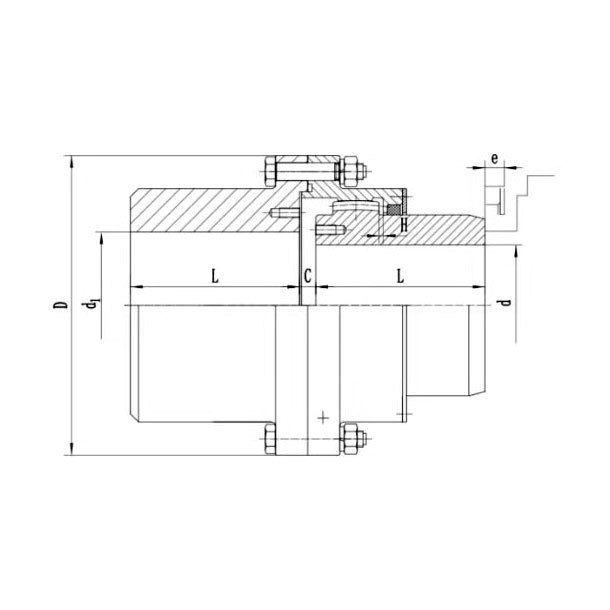

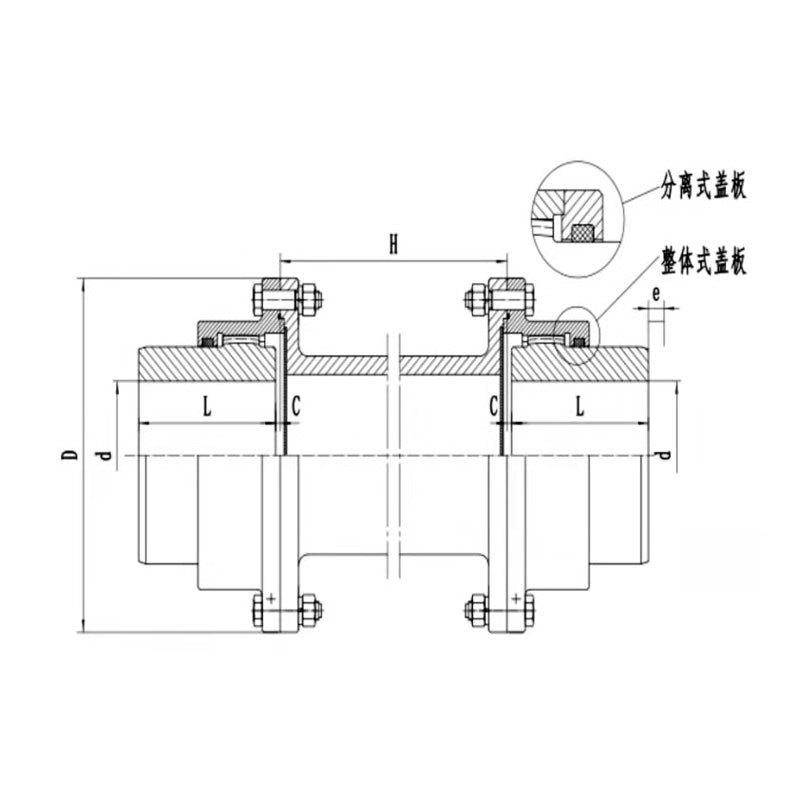

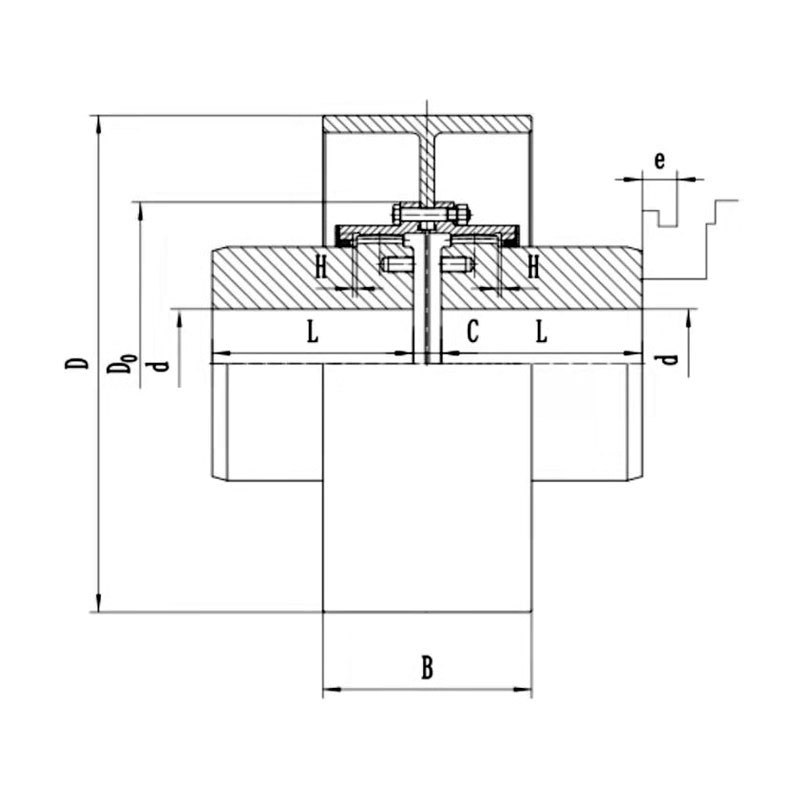

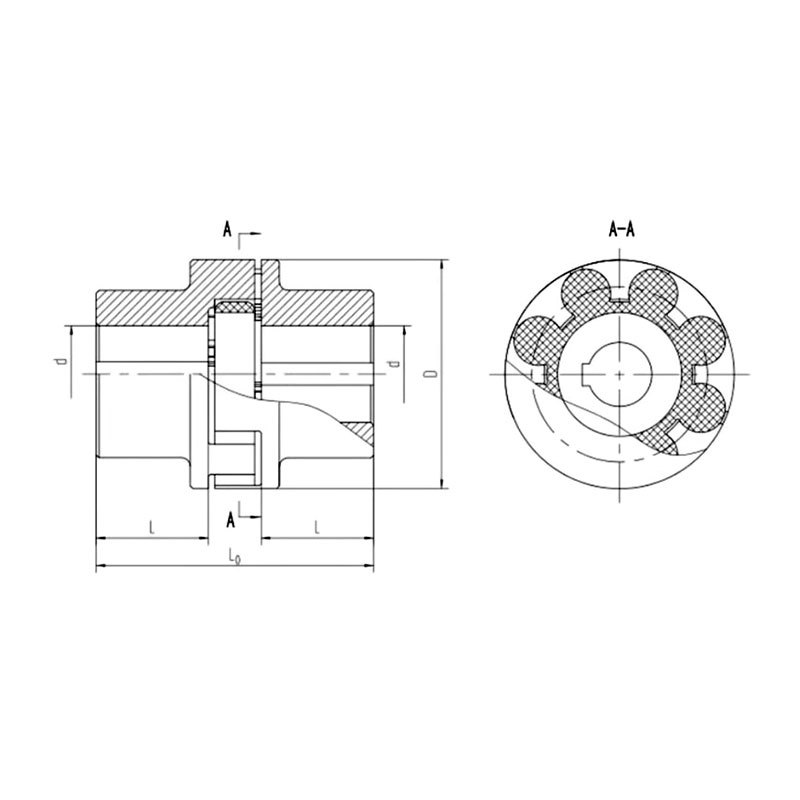

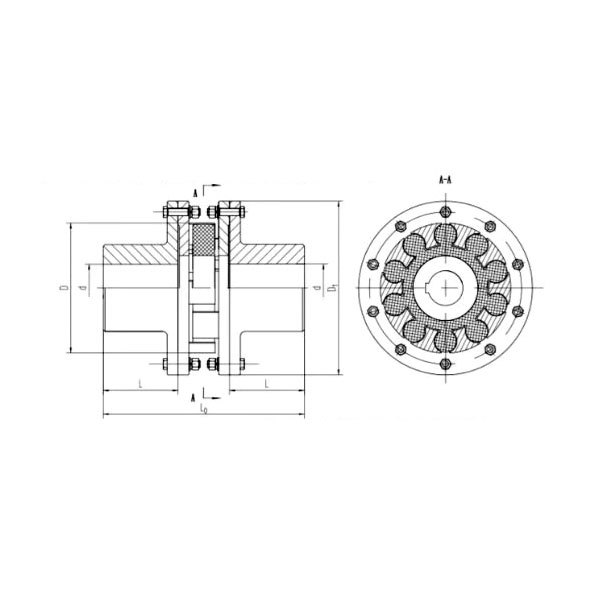

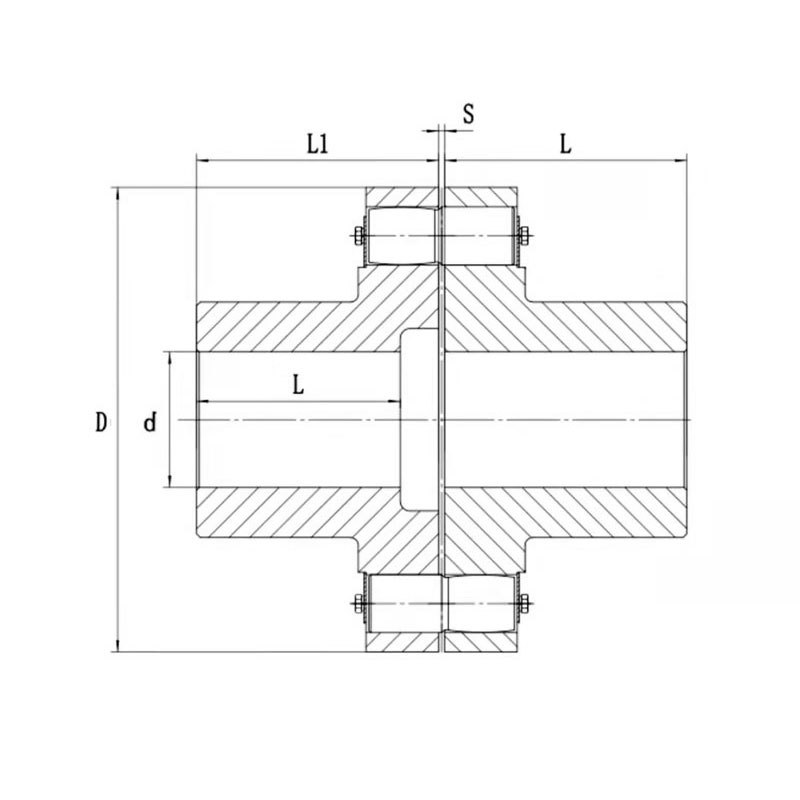

The WB-type rubber-block coupling is primarily used in applications involving high torque, severe shocks, or reversible rotating machinery; it features a small angular deformation (1° to 2°). The structural configurations are shown in Figures 5.1 and 5.2, while the technical parameters and main dimensions are listed in Table 5-1.

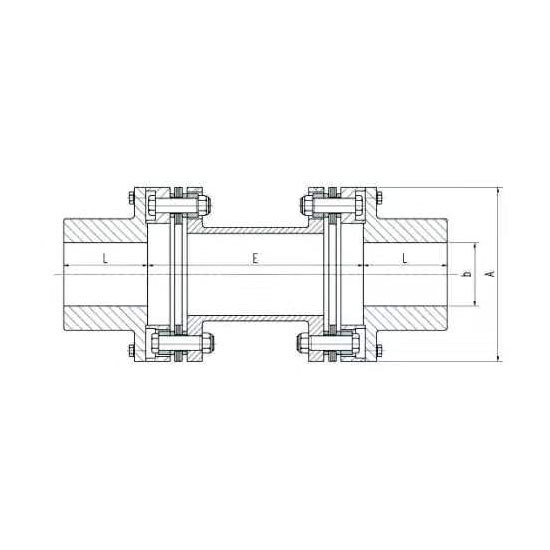

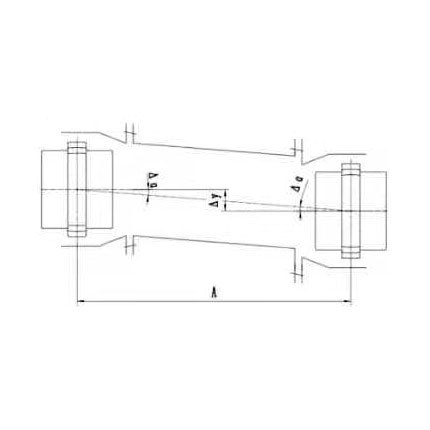

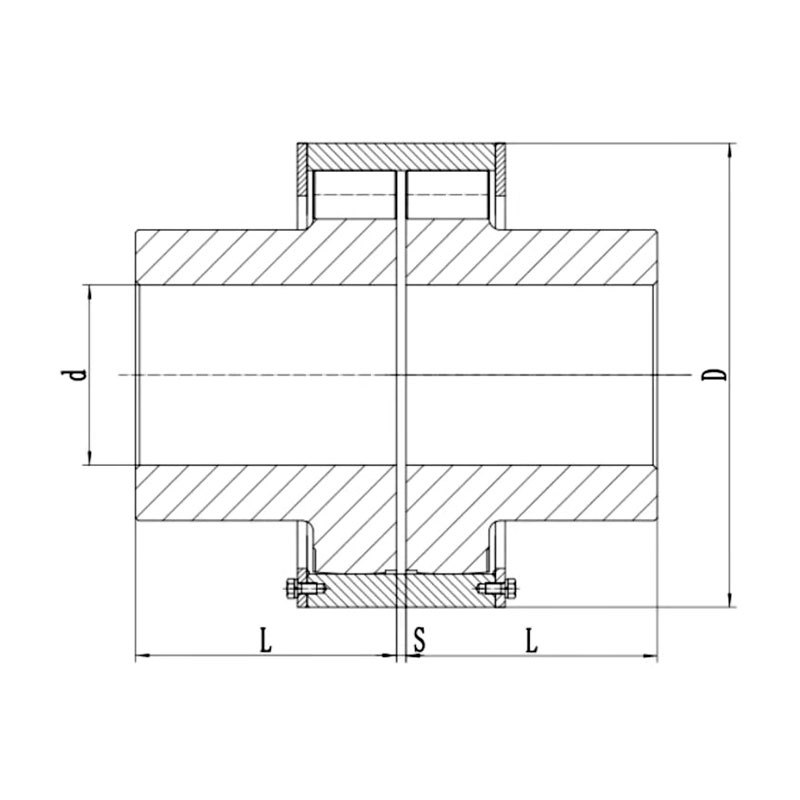

Figure 5.1 WB2.5-WB12 Type Rubber-Disk Coupling

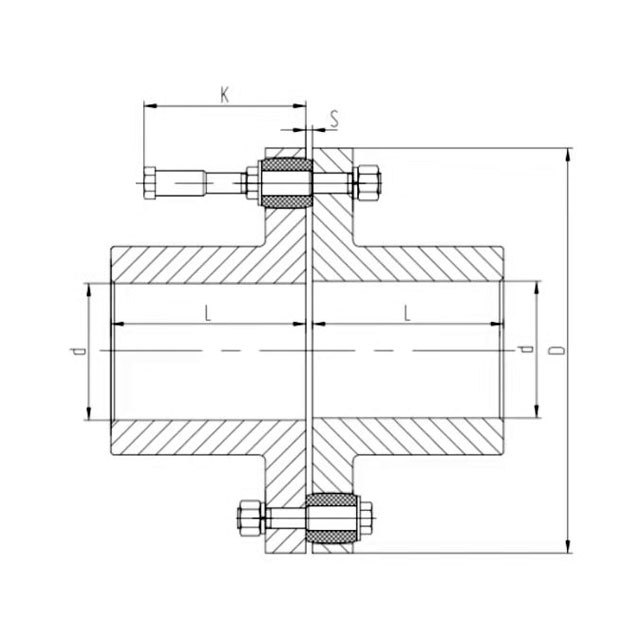

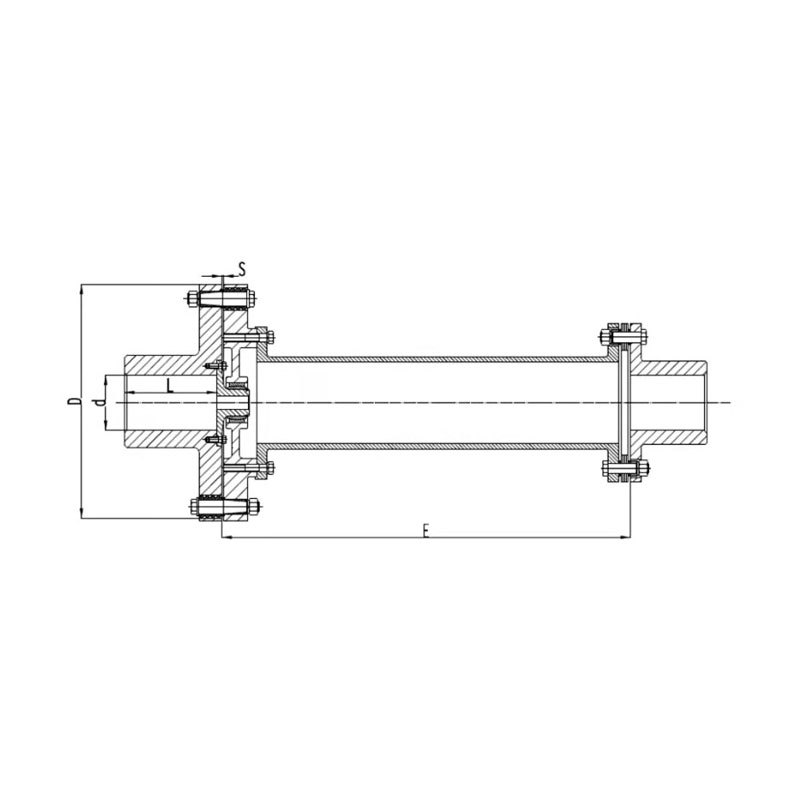

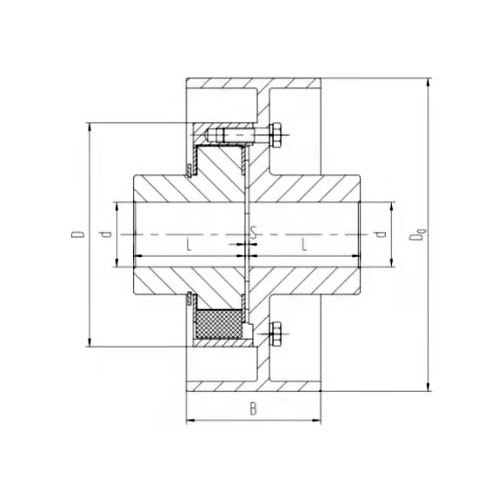

Figure 5.2 WB14-WB28 Type Rubber-Disk Coupling

Table 5-1: Technical Parameters and Main Dimensions of WB-Type Rubber Block Coupling

| Model | Peak torque kN·m |

Maximum rotational speed revolutions per minute |

Number of glue holes Z | Number of rubber blocks Quantity Z |

Maximum shaft hole d | D | L | S | K | W | Moment of inertia kg · m² |

Weight Kilogram |

Misalignment absorption capability | ||

| mm | Axial mm |

Radial mm |

Angular. | ||||||||||||

| 2.5 | 2.88 | 4470 | 12 | 12 | 76 | 260 | 70 | 3.2 | 73 | 0.16878 | 26 | 0.762 | 0.508 | 0.5 | |

| 3 | 5.29 | 3700 | 12 | 12 | 89 | 300 | 89 | 3.2 | 92 | 0.3451 | 45 | 0.762 | 0.508 | 0.5 | |

| 3.5 | 10.12 | 3250 | 12 | 12 | 108 | 360 | 108 | 4 | 130 | 0.8439 | 76 | 0.889 | 0.635 | 0.5 | |

| 4 | 14.61 | 2700 | 12 | 12 | 127 | 425 | 121 | 4 | 130 | 1.6791 | 117 | 0.889 | 0.635 | 0.5 | |

| 4.5 | 24.15 | 2660 | 12 | 12 | 133 | 450 | 125 | 4.8 | 178 | 2.2388 | 135 | 1.143 | 0.635 | 0.5 | |

| 5.5 | 37.95 | 2210 | 14 | 14 | 175 | 530 | 141 | 6.4 | 178 | 5.4897 | 227 | 1.270 | 0.889 | 0.5 | |

| 6 | 57.5 | 2030 | 16 | 32 | 200 | 575 | 156 | 6.4 | 203 | 8.5521 | 303 | 1.270 | 0.889 | 0.5 | |

| 6.5 | 86.25 | 1840 | 16 | 32 | 216 | 635 | 194 | 6.4 | 254 | 15.5382 | 450 | 1.270 | 0.889 | 0.5 | |

| 7 | 116.15 | 1710 | 16 | 32 | 232 | 685 | 213 | 12.7 | 159 | 22.1125 | 565 | 1.524 | 1.016 | 0.5 | |

| 8 | 155.25 | 1560 | 18 | 36 | 273 | 750 | 222 | 12.7 | 165 | 32.714 | 715 | 1.524 | 1.016 | 0.5 | |

| 9 | 190.9 | 1470 | 18 | 36 | 286 | 800 | 248 | 127 | 184 | 45.559 | 892 | 1.524 | 1.016 | 0.5 | |

| 10 | 278.3 | 1320 | 20 | 40 | 333 | 890 | 267 | 12.7 | 197 | 79.112 | 1230 | 1.524 | 1.016 | 0.5 | |

| 11 | 385.25 | 1200 | 20 | 40 | 381 | 980 | 318 | 12.7 | 232 | 138.214 | 1782 | 1.524 | 1.016 | 0.5 | |

| 12 | 593.4 | 1100 | 22 | 44 | 406 | 1060 | 375 | 12.7 | 273 | 223.88 | 2480 | 1.524 | 1.016 | 0.5 | |

| 14 | 828 | 1020 | 24 | 48 | 448 | 1142 | 406 | 19 | 302 | 20 | 330.6 | 3185 | 1.524 | 1.016 | 0.5 |

| 16 | 1092.5 | 880 | 24 | 72 | 540 | 1350 | 425 | 19 | 314 | 20 | 741.82 | 4830 | 1.524 | 1.016 | 0.5 |

| 19 | 1966.5 | 750 | 28 | 84 | 635 | 1568 | 508 | 19 | 362 | 20 | 1713.9 | 8073 | 2.286 | 1.524 | 0.5 |

| 22 | 3254.5 | 580 | 32 | 96 | 864 | 2020 | 610 | 25 | 362 | 25 | 5255.8 | 14562 | 3.175 | 2.032 | 0.5 |

| 25 | 4864.5 | 580 | 32 | 160 | 864 | 2020 | 724 | 27 | 540 | 52 | 6696.1 | 19113 | 3.175 | 2.032 | 0.5 |

| 28 | 6497.5 | 580 | 32 | 192 | 864 | 2020 | 889 | 30 | 714 | 132 | 8776.8 | 25182 | 3.175 | 2.032 | 0.5 |

CB and WB format selection

If the torque analysis of the shaft has already been performed, select C B or WB based on the results. If the torque analysis of the shaft has not been performed, follow the principles below:

a) For diesel engine-driven systems, please consult Schenck Engineering Department.

b) Motor-driven: If direct drive is used without gears and the vibration or impact originates from the motor side, then use WB; CB-type can also be used when it is more suitable.

c) Gear reducer: If the vibration or impact originates from the driven side, a WB-type is typically used; otherwise, a CB-type is employed.

d) Speed increaser: If the impact and vibration originate from the high-speed end, use the WB type; otherwise, if this is not the case, use the CB type.

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products