JS Snake Spring Coupling

Category

Contact Information

Detailed introduction

The snake-spring coupling features a simple structure, convenient maintenance, and excellent performance in shock absorption, vibration damping, and handling variable loads, making it a simpler and more ideal medium- to heavy-duty coupling.

The snake spring is made from high-strength alloy steel and undergoes a rigorous heat treatment process to meet even higher requirements for both rigidity and flexibility. The spring’s surface is precisely sandblasted, which densifies the molecular structure of the compressed surface, resulting in excellent wear resistance and an extended service life.

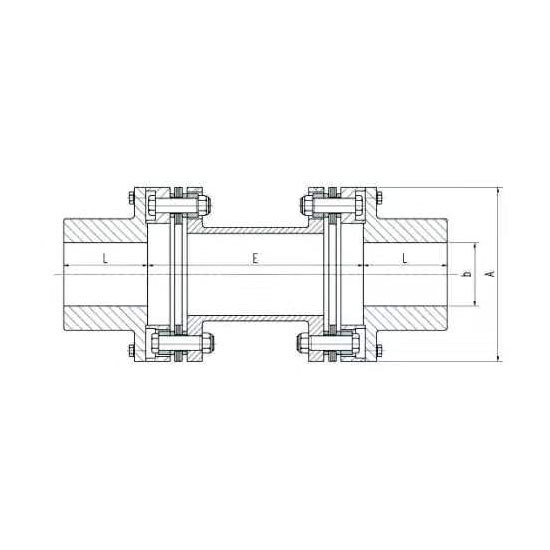

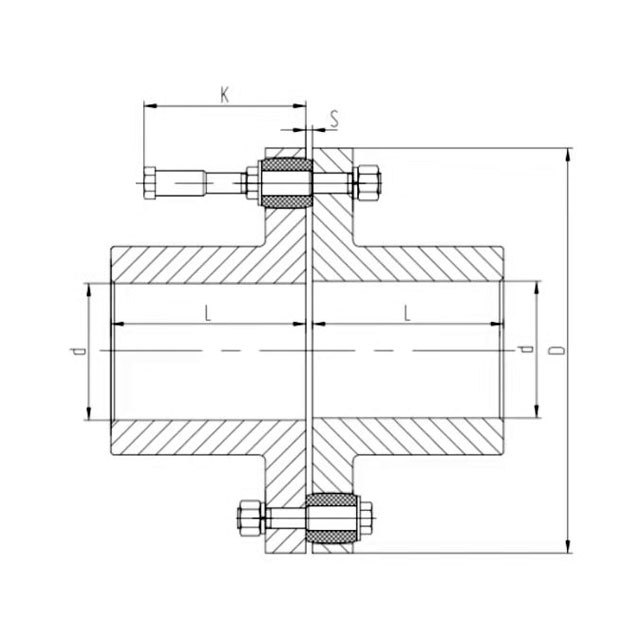

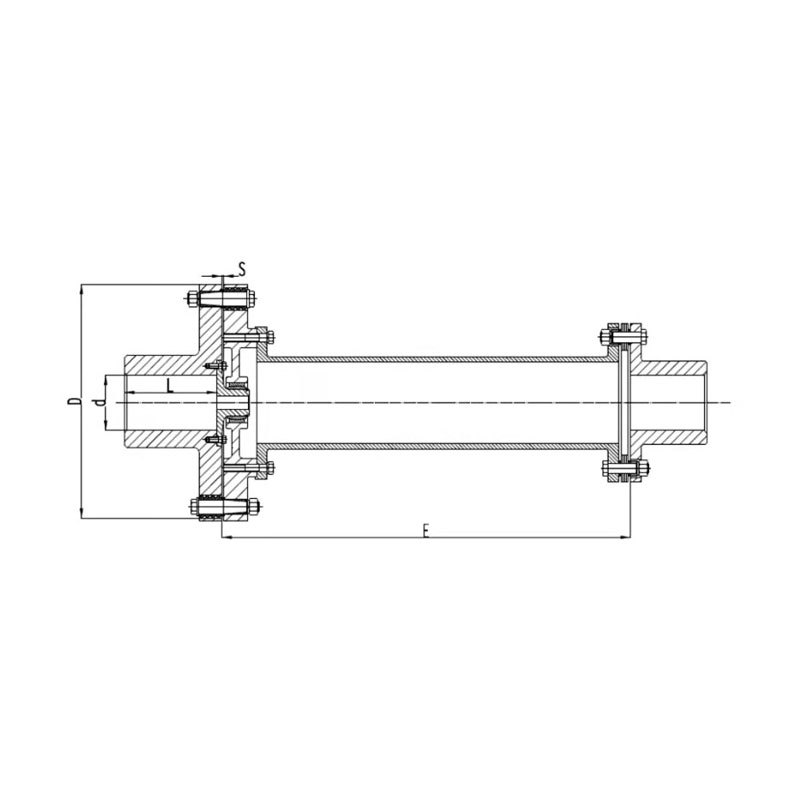

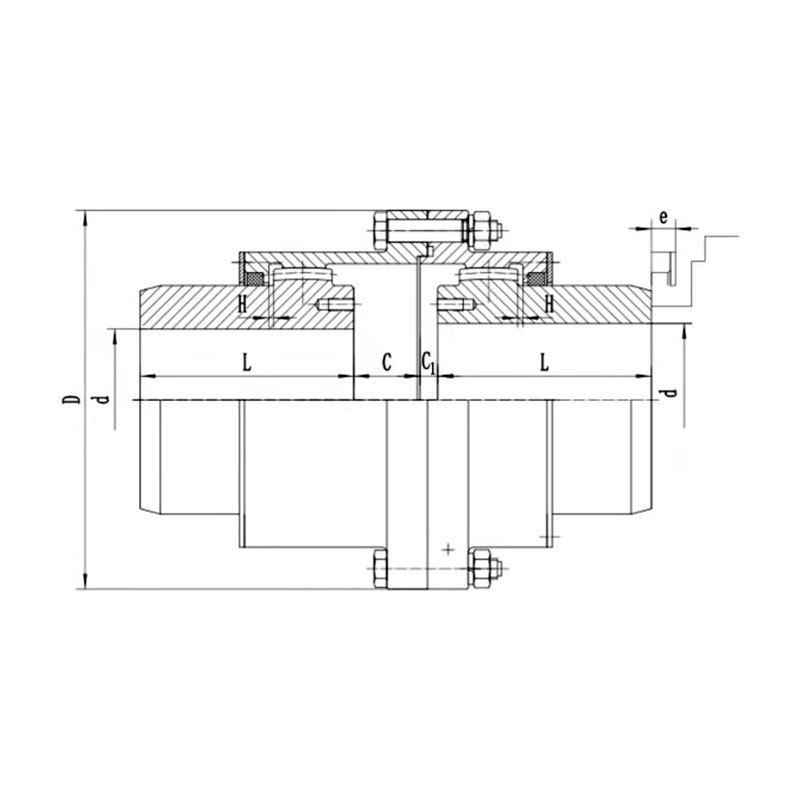

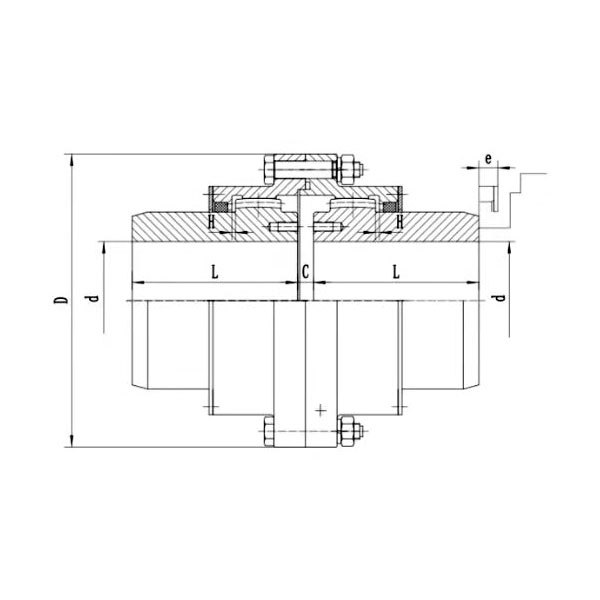

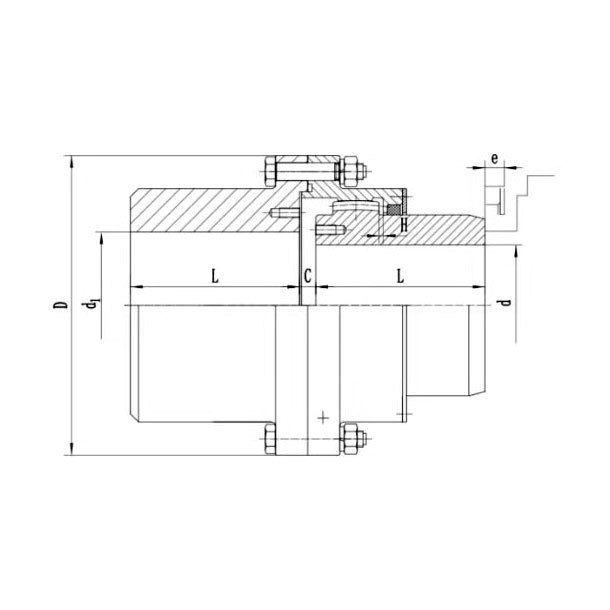

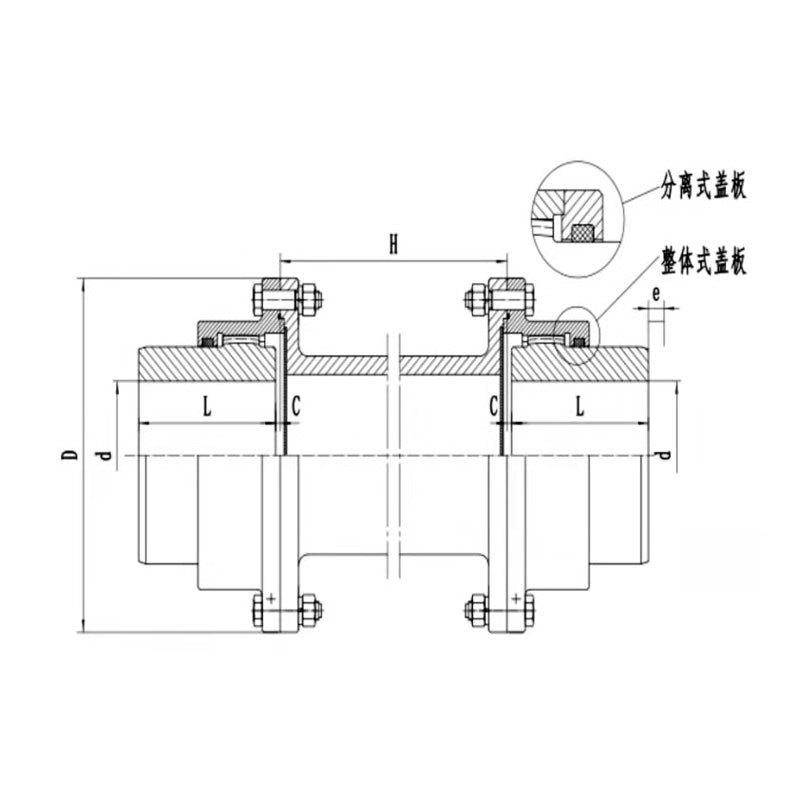

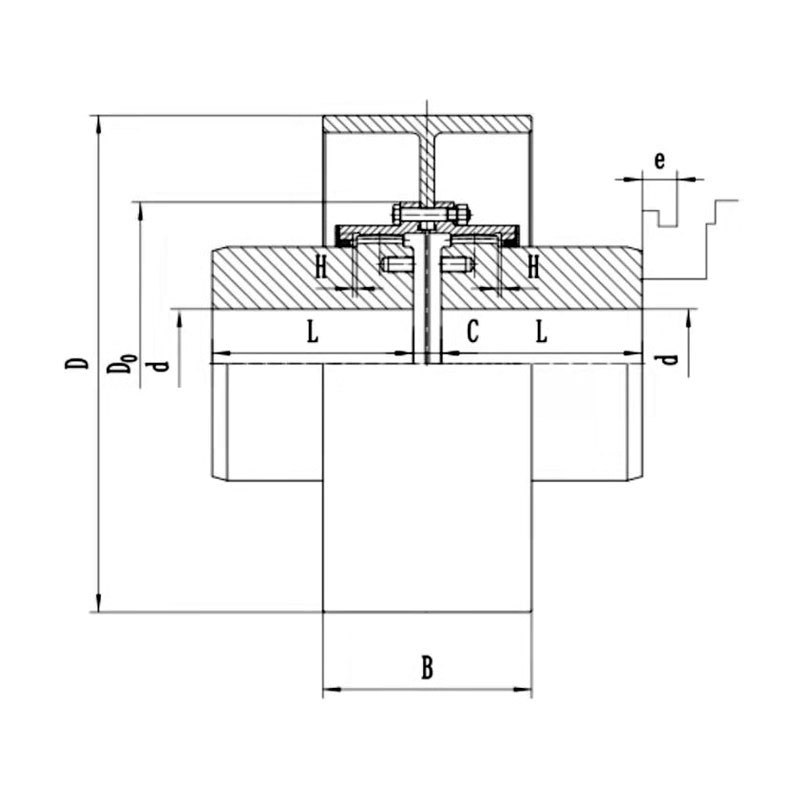

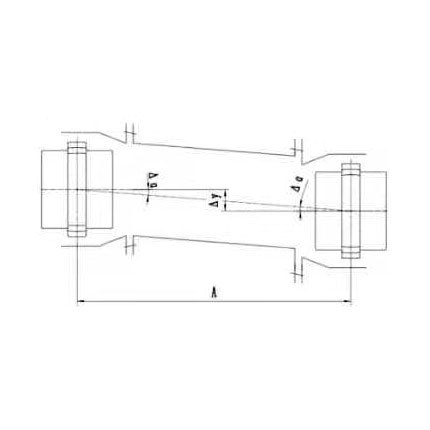

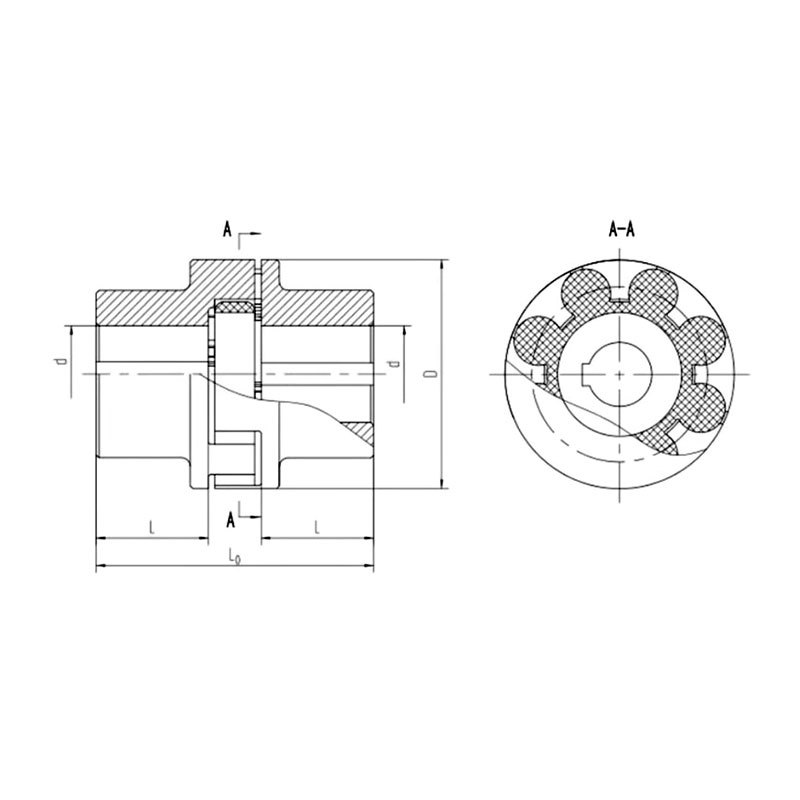

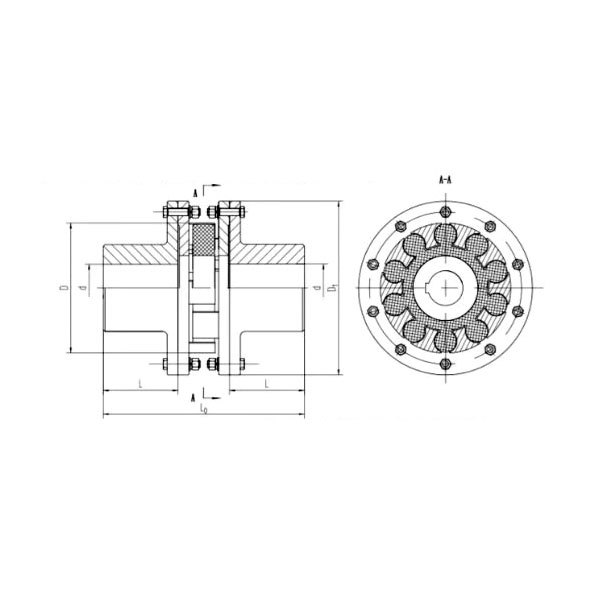

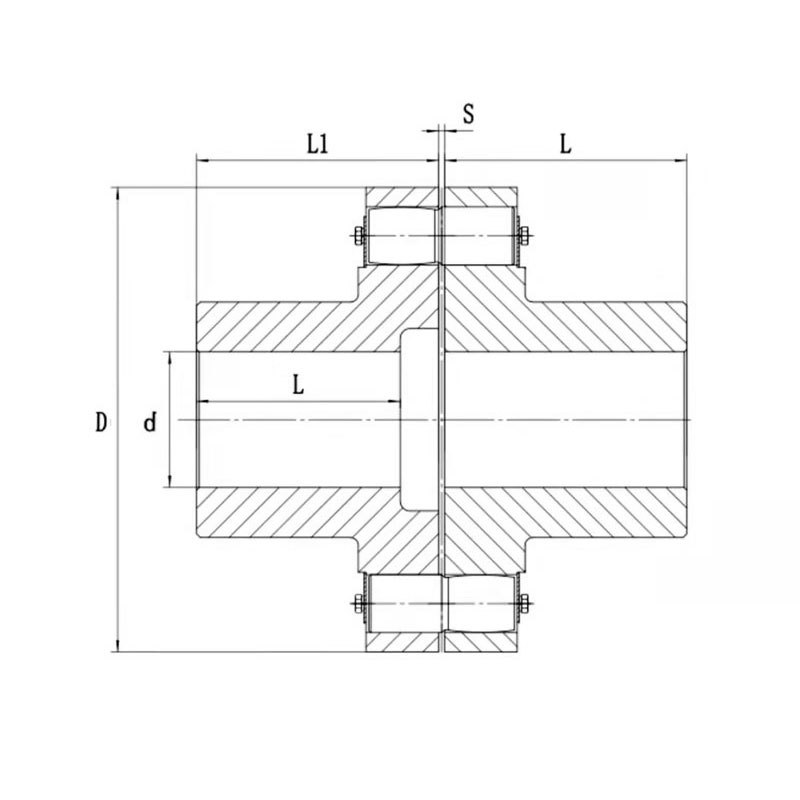

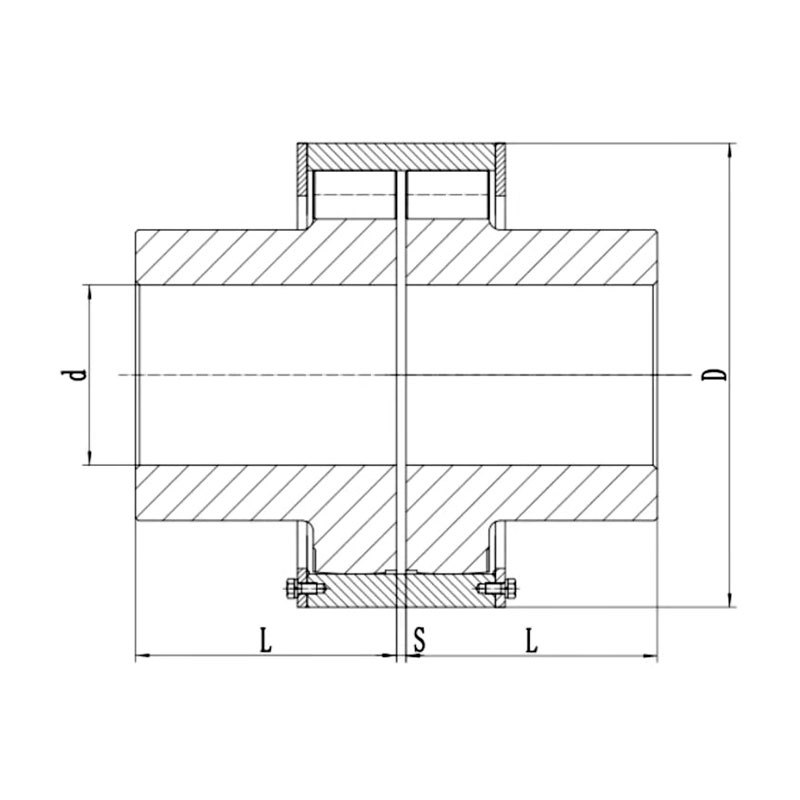

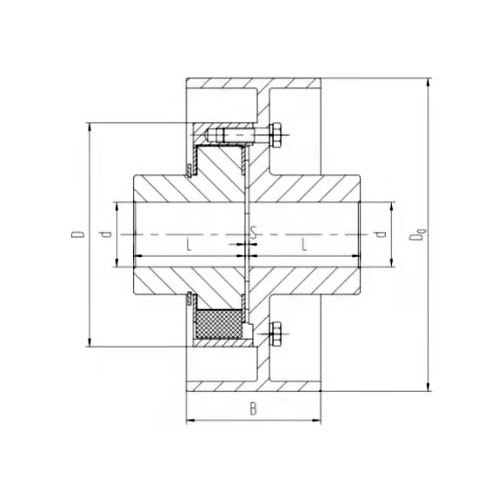

Its structural type is shown in Figure 9.1, and the technical parameters and main dimensions are listed in Table 9-1.

Figure 9.1 JS-type Snake Spring Coupling

Table 9-1: Technical Parameters and Main Dimensions of JS-Type Snake Spring Couplings

| Model | Nominal torque /N.m |

Permissible rotational speed /r· min -1 |

Shaft hole diameter d | L0 | L2 | D | Gap t |

Quality /kg |

Moment of inertia /kg · ㎡ |

Lubricating oil /kg |

| JS1 | 45 | 4500 | 18, 19 | 97 | 66 | 95 | 3 | 1.91 | 0.0014 | 0.0272 |

| 20, 22, 24 | ||||||||||

| 25, 28 | ||||||||||

| JS2 | 140 | 22, 24 | 97 | 68 | 105 | 2.59 | 0.0022 | 0.0408 | ||

| 25, 28 | ||||||||||

| 30, 32, 35 | ||||||||||

| JS3 | 224 | 25, 28 | 103 | 70 | 115 | 3.36 | 0.0033 | 0.0544 | ||

| 30, 32, 35, 38 | ||||||||||

| 40, 42 | ||||||||||

| JS4 | 400 | 32, 35, 38 | 123 | 81 | 130 | 5.44 | 0.0073 | 0.068 | ||

| 40, 42, 45, 48, 50 | ||||||||||

| JS5 | 630 | 4350 | 40, 42, 45, 48, 50, 55, 56 | 129 | 94 | 150 | 7.26 | 0.0119 | 0.0862 | |

| JS6 | 900 | 4125 | 48, 50, 55, 56 | 155 | 97 | 160 | 10.4 | 0.0185 | 0.113 | |

| 60, 63, 65 | ||||||||||

| JS7 | 1800 | 3600 | 55, 56 | 181 | 115 | 190 | 17.7 | 0.0451 | 0.172 | |

| 60, 63, 65, 70, 71, 75 | ||||||||||

| 80 | ||||||||||

| JS8 | 3150 | 65, 70, 71, 75 | 199 | 122 | 210 | 25.4 | 0.0787 | 0.254 | ||

| 80, 85, 90, 95 | ||||||||||

| JS9 | 5600 | 2440 | 75 | 245 | 155 | 250 | 5 | 42.2 | 0.178 | 0.426 |

| 80, 85, 90, 95 | ||||||||||

| 100, 110 | ||||||||||

| JS10 | 8000 | 2250 | 85, 90, 95 | 259 | 162 | 270 | 54.4 | 0.27 | 0.508 | |

| 100, 110, 120 | ||||||||||

| JS11 | 12500 | 2025 | 90, 95 | 304 | 191 | 310 | 6 | 81.2 | 0.514 | 0.735 |

| 100, 110, 120, 125 | ||||||||||

| 130, 140 | ||||||||||

| JS12 | 18000 | 1800 | 110, 120, 125 | 330 | 195 | 346 | 121 | 0.989 | 0.907 | |

| 130, 140, (150) | ||||||||||

| 160, 170 | ||||||||||

| JS13 | 25000 | 1600 | 120, 125 | 374 | 201 | 384 | 6 | 178 | 1.85 | 1.13 |

| 130, 140, 150 | ||||||||||

| 160, 170, 180 | ||||||||||

| 190, 200 |

Table 9-1: Technical Parameters and Main Dimensions of JS-Type Snake Spring Couplings

| Model | Nominal torque /N.m |

Permissible rotational speed /r· min -1 |

Shaft hole diameter d | L0 | L2 | D | Gap t |

Quality /kg |

Moment of inertia /kg · ㎡ |

Lubricating oil /kg |

| JS14 | 35500 | 1500 | 140, 150 | 370 | 271 | 450 | 6 | 227 | 3.49 | 1.95 |

| 160, 170, 180 | ||||||||||

| 190, 200 | ||||||||||

| JS15 | 50000 | 1300 | 160, 170, 180 | 402 | 278 | 500 | 309 | 5.82 | 2.81 | |

| 190, 200, 220 | ||||||||||

| 240 | ||||||||||

| JS16 | 63000 | 1200 | 180 | 438 | 307 | 566 | 448 | 10.4 | 3.49 | |

| 190, 200, 220 | ||||||||||

| 240, 250, 260 | ||||||||||

| 280 | ||||||||||

| JS17 | 90000 | 1100 | 200, 220 | 484 | 321 | 630 | 619 | 18.3 | 3.76 | |

| 240, 250, 260 | ||||||||||

| 280, 300 | ||||||||||

| JS18 | 125000 | 1000 | 240, 250, 260 | 526 | 325 | 675 | 776 | 26.1 | 4.4 | |

| 280, 300, 320 | ||||||||||

| JS19 | 160000 | 900 | 280, 300, 320 | 566 | 355 | 756 | 1057 | 43.5 | 5.62 | |

| 340, 360 | ||||||||||

| JS20 | 224000 | 820 | 300, 320 | 623 | 432 | 845 | 13 | 1424 | 75.5 | 10.53 |

| 340, 360, 380 | ||||||||||

| JS21 | 315000 | 730 | 320 | 663 | 490 | 920 | 1785 | 113 | 16.1 | |

| 340, 360, 380 | ||||||||||

| 400, 420 | ||||||||||

| JS22 | 400000 | 680 | 340, 360, 380 | 703 | 546 | 1000 | 2267 | 175 | 24.06 | |

| 400, 420, 440, 450 | ||||||||||

| JS23 | 500000 | 630 | 360, 380 | 749 | 648 | 1087 | 2950 | 339 | 33.82 | |

| 400, 420, 440, 450, 460, 480 | ||||||||||

| JS24 | 630000 | 580 | 400, 420, 440, 450, 460 | 815 | 698 | 1180 | 3833 | 524 | 50.17 | |

| JS25 | 800000 | 540 | 420, 440, 450, 460, 480, 500 | 877 | 762 | 1260 | 4682 | 711 | 67.24 | |

| JS26 | 1100000 | 460 | 520 | 1100 | 800 | 1350 | 5825 | 930 | 82.35 | |

| JS27 | 1300000 | 340 | 550 | 1120 | 850 | 1450 | 6600 | 1142 | 101.42 |

Keywords

Online Consultation

Contact us today for a free expert consultation!

Related Products