Contact Information

Shenyang Shenke Power Machinery Co,. Ltd.

Address: No. 34 Jia, Kaifa Avenue, Tiexi Economic and Technological Development Zone, Shenyang

Email:sincflex@vip.163.com

Phone:+86 24 25830257

Mobile phone:+86 15940017261

Fax: +86 24 25308993

What are the effects of a loose coupling bolt?

Release date:

2019-12-27

When using a coupling, if the coupling bolts become loose or slip out, the normal operation of the mechanical equipment will be affected. Now, let’s take a look at the specific impacts caused by loose coupling bolts: A coupling is used to connect…

When using a coupling, if the coupling bolts become loose or slip out, the normal operation of the mechanical equipment will be affected. Now, let’s take a look at the specific impacts caused by loose coupling bolts.

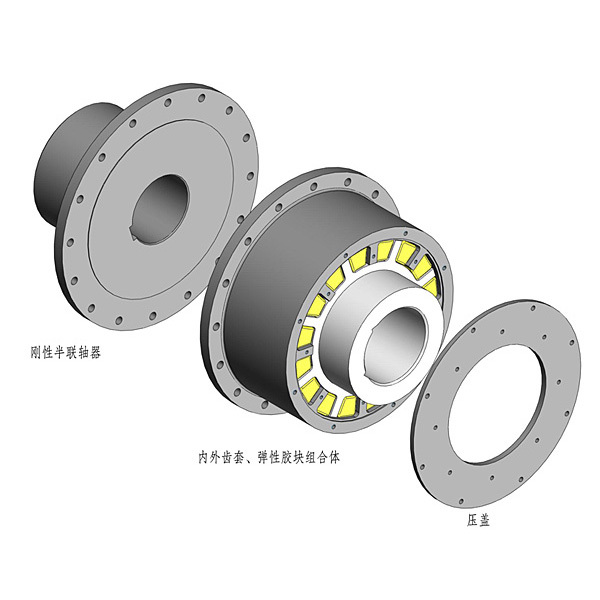

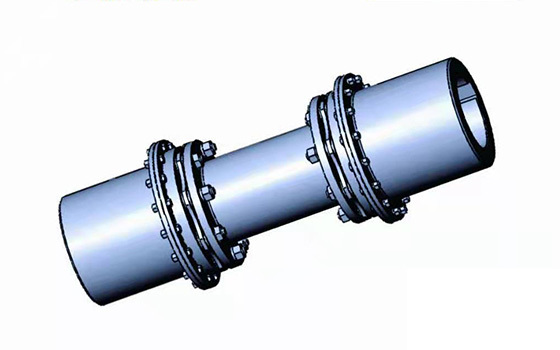

The coupling firmly connects the driving shaft to the driven shaft, enabling them to rotate together. There are three primary methods by which couplings transmit torque: bolted connections, frictional force at the coupling’s mating surfaces, and a combination of both. When using the combined method—where both bolted connections and frictional force are employed—each bolt must experience uniform torque. This ensures that, during load fluctuations, the force transmitted by each bolt increases or decreases equally across the board.

The coupling is secured by just two bolts, and if the shear forces on these two bolts are equal, the coupling experiences only torque. However, if the shear forces differ between the two bolts, an additional force—acting through the rotor’s center—also comes into play. This force, F, varies with changes in the unit’s load, which is why the unit’s vibration pattern itself shifts as the load fluctuates. Beyond force F, bolt loosening can lead to misalignment between the two half-couplings and cause the coupling’s mass center to shift, introducing new, unbalanced masses. These imbalances generate extra vibrational forces, often resulting in sudden spikes in vibration levels. Additionally, the misalignment of the coupling halves tends to change dynamically with varying loads, further contributing to the phenomenon of vibration surges that accompany load fluctuations.

In the coupling industry, premature coupling failures often occur due to loose fasteners, leading to significant financial losses. That’s why coupling manufacturers carefully select appropriate fastening methods to ensure the long-term, reliable, and trouble-free operation of their products. When purchasing couplings, it’s crucial to pay attention to whether the manufacturer has chosen a suitable locking mechanism—for example, membrane couplings typically use lock-type nuts, and extra care should be taken during installation and operation.

Keywords:

Previous page

Next page

Related Blog

2018-11-22

Improve the synchronized automatic clutch

2018-11-22