SINCE 1988

Shenyang Shenke Power Machinery Co,. Ltd.

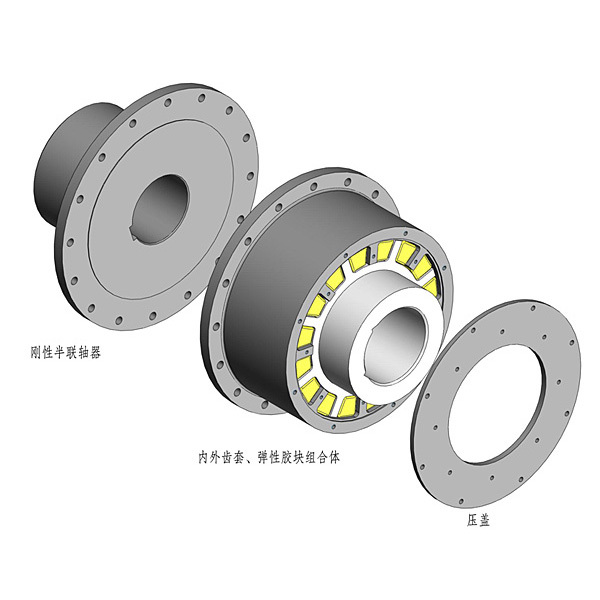

Shenyang Shenke Power Machinery Co,. Ltd. was established in 1988 and is located in the Shenyang Economic and Technological Development Zone. The company occupies a site of 100 mu and has a registered capital of 40 million yuan. Primarily focused on the manufacturing and processing of couplings, clutches, and related components, our main products include diaphragm couplings, diaphragm discs, drum-type gear couplings, elastic sleeve pin couplings, serpentine spring couplings, and other types of couplings and clutches. Additionally, we undertake custom production of both standard and non-standard products tailored to customer specifications.

1998 Year

100 Mu

1 Million Plus

100+

Choose ABT TURBO – Building Quality

Survive through quality, thrive through technology.

Independently developed

Our company boasts an outstanding R&D team.

01

Already secured multiple technical safeguards

02

Boasting a complete processing workflow and strong independent design capabilities.

03

Customized Processing

Offering OEM/ODM services

01

Accepting personalized customization of logos, packaging, and more

02

Achieve fast customization at low cost

03

Service Advantages

Swift response, expert answers

01

Providing customers with the right personalized services

02

Years of industry experience, direct factory supply

03

Serving the Globe

External collaboration is a key strategy for ABT TURBO. In the early 1990s, Schenck introduced coupling manufacturing technology from abroad, and in 1995, the company partnered with Xi'an Jiaotong University to jointly develop design software. To date, Schenck’s products are exported to 27 countries worldwide.

Production Series

Production Experience

Country of Production

BLOG

2018-11-22